New Electronics Fuel Formula E Racing

As the racing series continues, we take a closer look inside the new Gen2 Formula E race car to learn about the new electronics packages that make this machine faster, safer, and more powerful than previous versions.

The electronics industry takes a special interest in Formula E racing, as the championship series for electric vehicles is an important testing ground and demonstration venue for new automotive technologies. The vehicles that we see racing on urban courses through cities around the world are fantastic and futuristic, achieving speeds and battery powers that could have only been dreamed about a few years ago.

Gradually, these technologies are becoming mainstream, pushing industry to innovate even better iterations for racing. This season, a new version of the race car debuted. The Gen2 car has double the power and range, and can reach speeds of up to 280km/h (174mph), a significant increase over the the Gen1 Spark Renault SRT 01E’s 225km/h (140mph) potential. Its battery also lasts twice as long as the one in the Gen1 vehicle, which means the need to swap cars mid-race has been eliminated, and power output has increased from 200kW to 250kW.

Many connector suppliers and distributors, including Würth Elektronik, LEMO, Mouser, TTI Inc., Molex, and AVX sponsor or take part in research and development for Formula E cars and enjoy rooting for machines that contain their components. What happens at Formula E doesn’t stay on the race course, either.

The Nissan e.dams team heads to Morocco for the Marrakesh ePrix. LEMO is sponsoring the Nissan E.dams Formula E racing team.

“The connector development and internal know-how we gain through our work for Formula E will be translated into other markets and allows LEMO to approach other markets, including commercial drones and high-end motorbikes,” said Serge Buechli, marketing manager for LEMO, which is sponsoring the Nissan E.dams team this season. (LEMO previously sponsored the Renault e.dams team.) “The Formula E effect is well received in the offices. As LEMO has offices located worldwide, engineers and other employees try to see the race if it is near their location.”

Audi e-tron FE05 #11 (Audi Sport ABT Schaeffler), Lucas di Grassi

Oliver Opitz of Würth Elektronik eiSos GmbH &Co. KG, Technology Partnership eMotorsports

We talked with Oliver Opitz of Würth Elektronik eiSos GmbH & Co. KG, Technology Partnership eMotorsports, about the company’s work with AUDI SPORT team to develop the drive train, inverter, and electronic peripherals used in the Gen2 Formula E race car.

What can the new car do that the Gen1 car could not?

Run a single race without a pit stop/car swap, because its battery capacity is almost twice as big. With power up to 250kW for qualifying and 200kW for the race, Gen2 is faster. It also offers the HALO head protection device, meaning security to the driver is bigger and better. It has brake-by-wire for the rear brakes and cooling through brake ducts for the front brakes. New all-weather tires are lighter and have less rolling resistance. Overall, the electronics have improved a lot over the last four years, which results in way higher efficiency and regeneration levels.

What should we know about the new electronics?

The focus for electronics was on efficiency, performance, and reliability, as well as flexibility in terms of the software used for each single connected device. The new brake-by-wire system is controlled by the Electronic Control Unit (ECU). The electronics for the ATTACK MODE are totally new, as there was no ATTACK MODE in the first four seasons.

What Würth Elektronik components are in the new car?

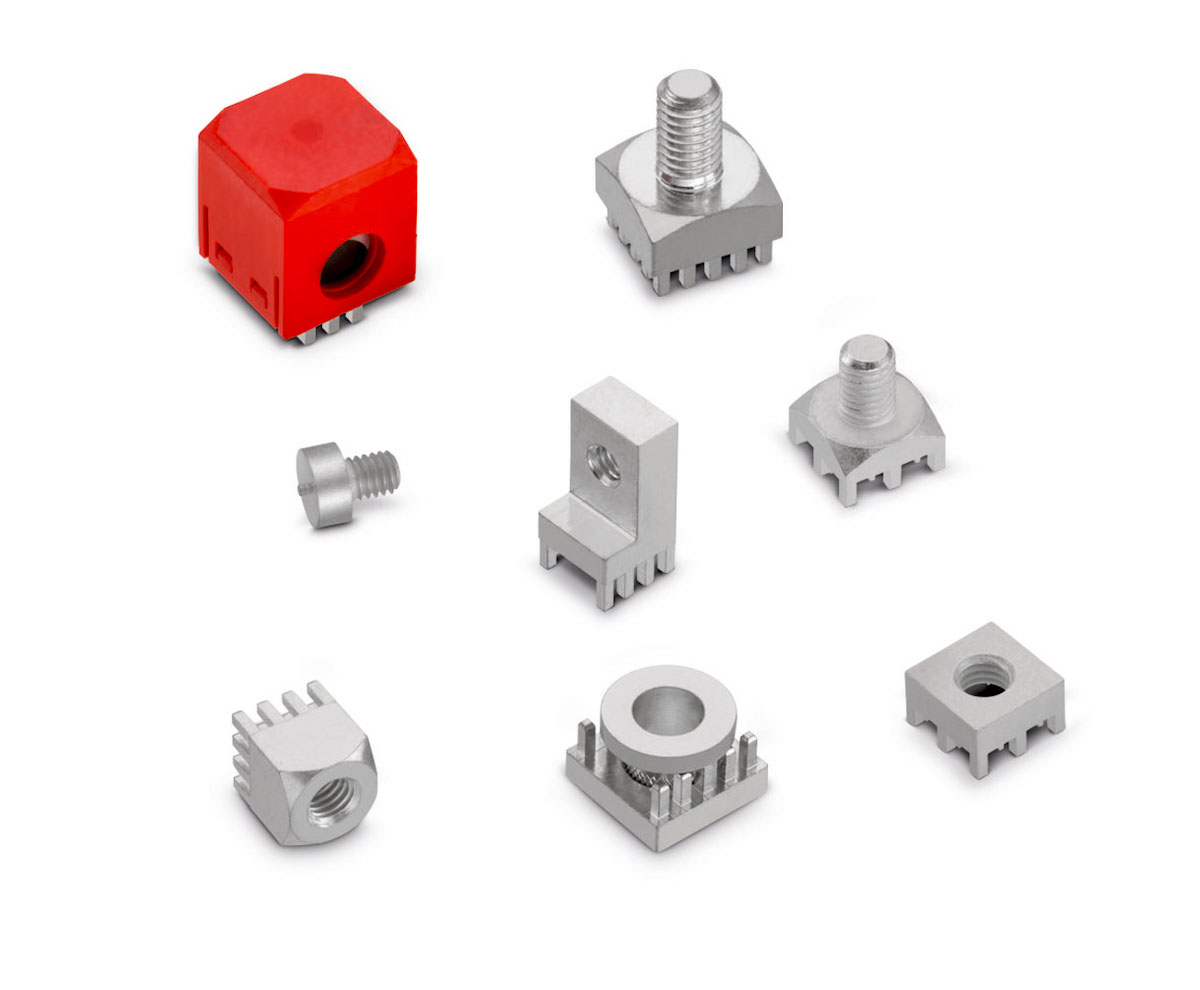

REDCUBES, passive components like inductors and capacitors, and of course the printed circuit boards. The portfolio will increase over the next year, as we have more and more freedom with AUDI SPORT to develop on Gen2, especially as we grew our portfolio over the last two years with new resistors, crystals, and quite important sensors and wireless modules. We really put research into it and it took almost six months to develop a new and game-changing passive component for the car.

Würth Elektronik’s REDCUBE press-fit plugs and connectors

Do you work with other electronics companies on this project?

We work closely with research facilities to improve continuously in regards to materials used in our components. Besides that, we do not involve external companies within our portfolio; we have the knowledge and experience in our product sector of components, as well as PCBs.

Have any components used in Formula-E racing become available for the consumer or commercial markets?

All the knowledge we’ve gained is applied during the development, design, and testing of new products for similar markets like e-mobility. There, we have strategic partnerships with a well- known manufacturer. The racing series is a harsh environment and we appreciate being able to test in such an environment, besides our extensive quality tests in our test facilities.

How does being involved with Formula-E affect life at Würth Elektronik?

The technology partnerships and especially our engagement in the Formula E series is present every day. This starts at the big entrance of the headquarters, with presentations about the topic and a 1:7 sized replica of the Gen2 car. Analog and digital information, as well as advertising material (coffee cups, note pads, etc.) with the claim “We speed up the future” are very popular here. We have our own eMotorsports fashion collection too. It’s one way to say thank you to the employees and partners who did a great job for the company. At the “home race” in Berlin, employees have the chance to be invited to the Berlin Tempelhof circuit or they watch from home and keep their fingers crossed for the team Audi Sport ABT Schaeffler, and especially for our drivers, Lucas and Daniel. The enthusiasm for our Formula E engagement is enormous and we are very proud of it.

Follow the races online as cities around the world host, culminating in a double-header season finale in New York City.

- March 10, 2019 | Hong Kong

- March 23, 2019 | Sanya

- April 13, 2019 | Rome

- April 27, 2019 | Paris

- May 11, 2019 | Monte Carlo

- May 25, 2019 | Berlin

- June 9, 2019 | Bern

- July 13 and 14, 2019 | New York

Like this article? Check out our 2018 interview with TE engineer Paul Webb at the conclusion of the fourth season of Formula-E, our automotive, e-mobility, electric car, and New Technology articles, our Automotive Market page, and our other 2019 articles.

- Meet the Connector: DIN Standard Connectors - April 16, 2024

- Software-Driven Radio Reinvigorates Old Technology - April 9, 2024

- What is a Busbar? - April 2, 2024