How to Specify Rail-Industry Ethernet Networks: Five Key Considerations and Why Connectors Are Critical

Data demands are exceeding what legacy technology can handle. See why more train manufacturers and system integrators are moving towards rail-industry Ethernet.

The rail industry’s accelerating demand for higher bandwidth requirements has outpaced what the existing Train Communication Network (TCN) standard for data communication can provide.

Designed for real-time applications, the TCN standard is a hierarchical combination of two fieldbus systems: a wire train bus (WTB), which connects the equipment within a vehicle, and a multifunction vehicle bus (MVB), which connects the vehicles. This solution became the standard thanks to its low cost, extreme reliability, and simplicity. With WTB and MVB, there’s no risk of message collision, and when something does go wrong, it’s a quick fix.

On-board surveillance, information, and entertainment systems increase railway bandwidth demands.

Even so, a proliferation of new sensors, on-board processing equipment, and other electronic systems have flooded the rail transportation industry in recent years, causing bandwidth requirements to skyrocket well beyond what any fieldbus can provide.

In response, leading global train manufacturers have begun to supplement legacy systems with Ethernet technology. Currently, rail-industry Ethernet is primarily used for on-board video surveillance and information or entertainment systems, while most other systems still function off separate TCN fieldbus interconnection networks.

Full Rail-Industry Ethernet is on its Way

Soon, Ethernet will replace TCN entirely. It will carry all data types needed for control, security, and passenger information, ranging from announcements to propulsion and lighting.

Ethernet technology provides unlimited network length and reliability, with speeds surpassing 1Gb/s (compared to TCN’s 1Mb/s). This high level of performance is also available from off-the-shelf products, eliminating the higher customization, maintenance, and replacement costs typical of rail-specific network equipment.

Five Key Considerations for Specifying Rail-Industry Ethernet Networks

Interested in upgrading your network? Follow these five steps to ensure a smooth, cost-effective transition.

Step 1: Identify the Implementation Challenges

Applying Ethernet technology in the on-board environment presents some technical challenges in terms of network configuration and component performance. The main challenge is compensating for fault tolerance. A network that’s resilient to the failure of one or more components is essential to accommodate for train architecture and the length of time it takes for an information packet to travel along a network path.

It’s also important to ensure the data cabling and connectors deployed in the network satisfy railway fire and smoke standards, as well as the mechanical and environmental requirements for vibration, sealing, and temperature. This is especially true for vehicle-to-vehicle interconnects, which are subject to a wider range of stresses and climate changes.

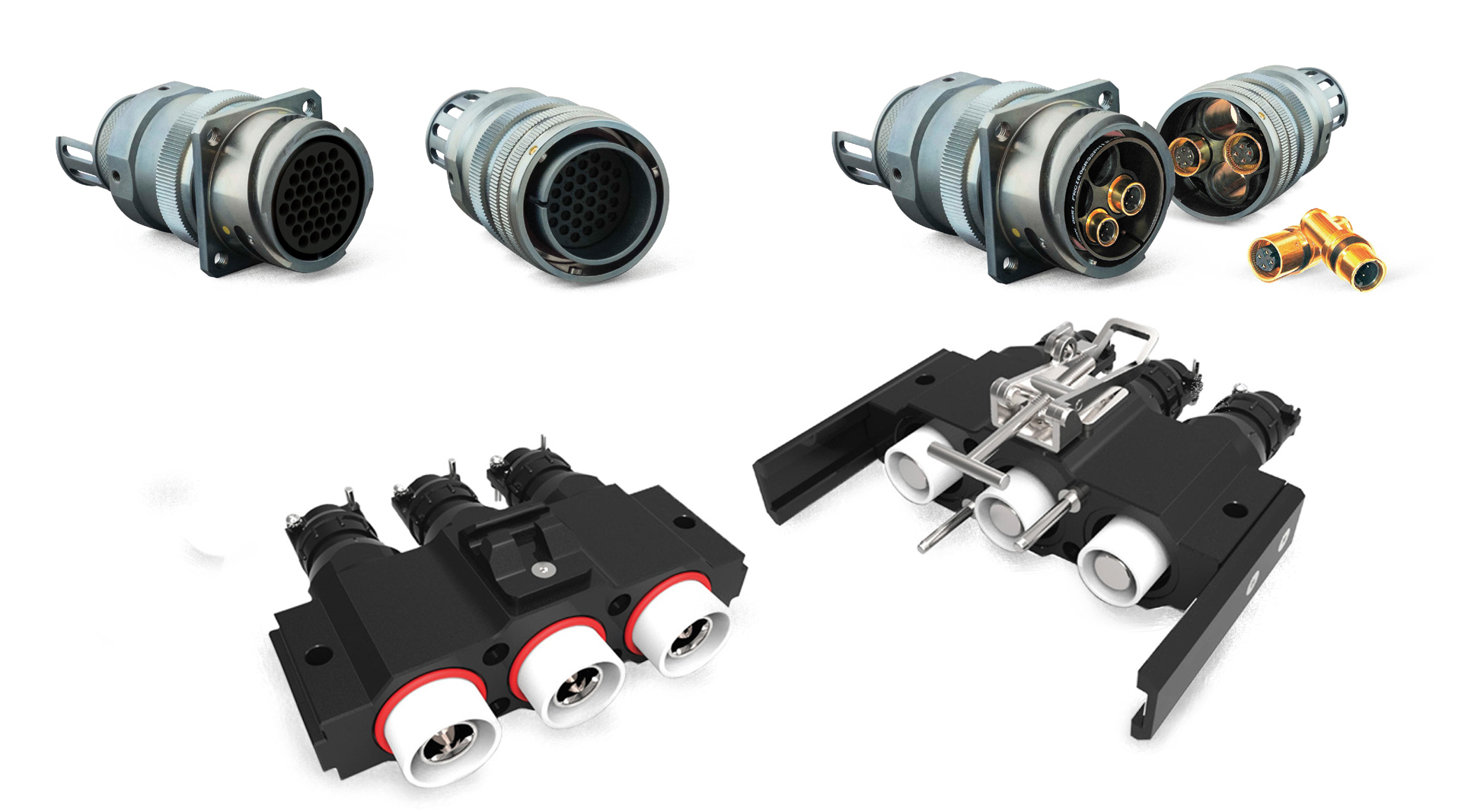

ITT Veam offers a broad range of interconnect solutions for harsh-environment rail applications.

Step 2: Define Network Performance Requirements

The next step is to define the performance requirements for rail-industry Ethernet networks in terms of either megabits or gigabits per second. This specification will depend upon the bandwidth requirements of the desired on-board systems.

Step 3: Select the Rail-Industry Ethernet Application

Choose a corresponding Ethernet application so that you can establish the network transmission hardware and protocol you will need. The appropriate Ethernet class for the application will be based on the network performance requirements, as well as several key variables, such as train topology, that affect the required channel length for the network.

Step 4: Consider Cabling Options

The two main cabling standards in use today include twisted pair copper cable and fiber optic cable. Twisted pair copper cabling, used in many Ethernet networks, utilizes a pair of wires to form a circuit that can transmit data. Fiber optic cable is a more advanced option that transmits data as pulses of light through thin, flexible tubes of glass. It’s faster and more secure, but also less versatile and much more expensive. Copper is more physically robust and cost-effective, but it provides slower speeds and is at risk of interference when unshielded.

Step 5: Establish Connector Requirements

Finally, one of the most critical considerations is the interconnection of jumper cables between vehicles. The ideal solution is one that works in harsh railway environments and fulfills all requirements for both standard TCN and high-speed Ethernet communication, as this helps to ensure that the transition to full-Ethernet trains is smooth and cost-effective. Selecting a connector with ruggedized RoHS-compliant plating can help ensure durability and performance. There are also connector solutions available with pretested cable assemblies.

Putting it Into Practice

A major high-speed Italian rail network operator implemented this approach when designing their Ethernet network. Borrowing directly from state-of-the-art data center design, they created a sophisticated network architecture that was able to overcome the challenges of train topology and achieve a high level of fault tolerance.

Italy has an extensive network of high-speed trains.

After defining network performance requirements, they used a highly specialized cabling scheme with fully shielded twisted pair cables and connectors to achieve performance well above Ethernet requirements. Then, when they realized they needed contacts with a higher network threshold than the 4-pole M12 contacts that have been adopted by a few leading European train manufacturers, they contracted with ITT to develop a custom solution.

ITT Veam has a rich history in rail connectors, and its CIR M12 connectors deliver industry-leading Gigabit per second Ethernet (GbE) transmission, optimal sealing, and extreme shock and vibration resistance especially designed for today’s harsh-environment rail communication applications. CIR M12 connectors are bayonet-coupling circular connectors that combine reliable and robust FRCIR connectors with M12 and coax contacts within a single shell to support up to 10GbE (i.e., up to Class FA ISO/IEC 11801 channel performance), MVB, WTB, and video lines. Available as 1-, 4-, and 7-way variants with 2-, 4- and 8-pole contact options, the series has a minimized circular footprint and is fully compliant with the latest state-of-the-art rail standards for fire and smoke.

ITT Veam’s CIR M12 Connectors for vehicle-to-vehicle railway connections.

ITT based its custom rail vehicle-to-vehicle interconnection solution for high-speed Italian trains on this series, delivering an 8-pole M12 contact that not only met the target performance level, but was able to mix both WTB and MVB fieldbus and Ethernet services by combining multiple M12 contacts in the same connector body.

On Track for the Future

The demand for higher rail industry connectivity is growing greater by the day. If you want to take advantage of the benefits of bandwidth-intensive data management systems and deliver a better experience for both operators and passengers alike, now is the time to get on board.

If you thoroughly evaluate your needs, follow these five steps, and build your network with proven, future-proof components, you can easily transition to a fault-tolerant rail-industry Ethernet network that adheres to the unique topology of individual trains and reliably performs under even the most severe mechanical and environmental stress.

Like this article? Check out our other Connector Basics articles, our Transportation Market Page, our 2019 Article Archives, and ITT’s Preferred Supplier Profile Page, which offers links to both editorial features and product solutions.

M12 Connectors Provide Rugged Performance for Industrial Ethernet