Connector Materials: Platings and Housing Product Roundup

This week’s Product Roundup highlights the advantages of various platings and housings from leading suppliers.

Connector Materials: Platings & Housing

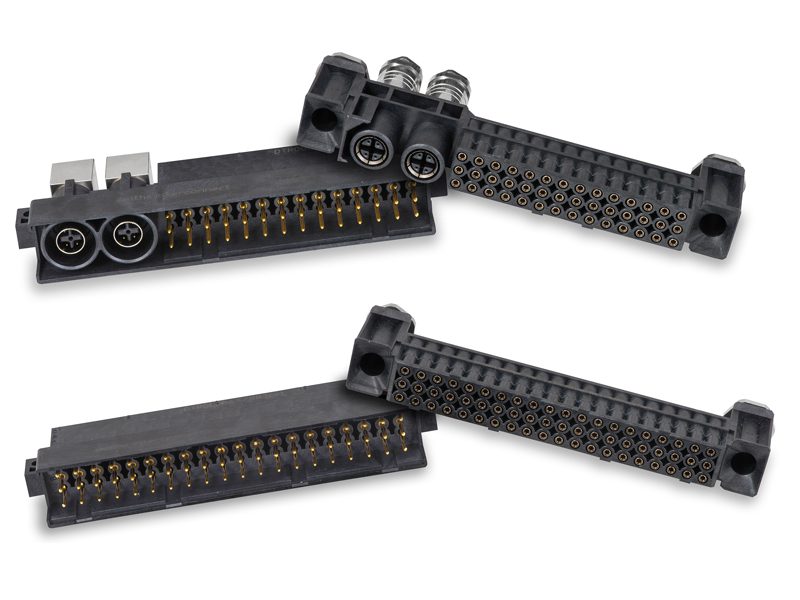

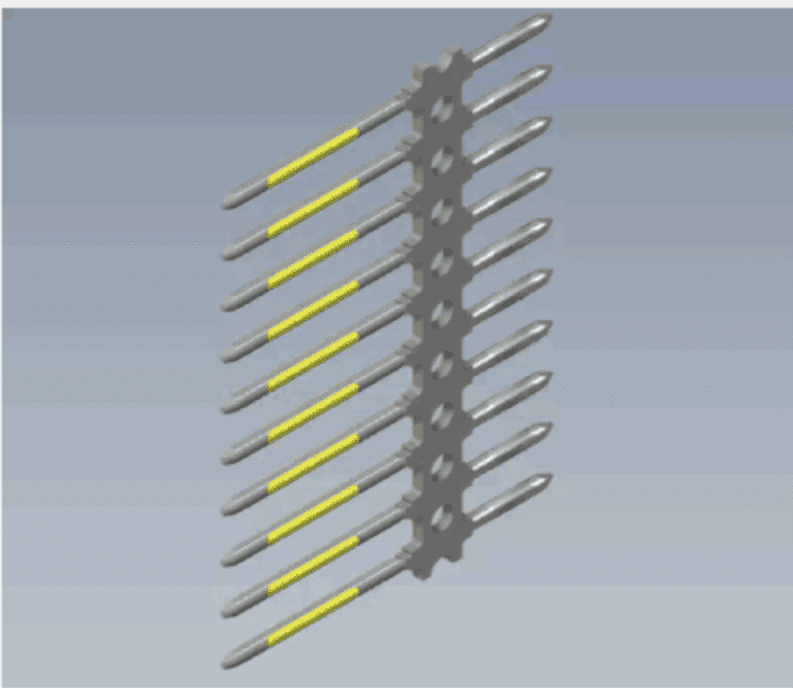

Intercompact from Smiths Interconnect features insulators in proprietary Liquid Cristal Polymer material and hyperboloid contact technology for an optimized insulation resistance in severe environment conditions. The very low contact resistance of the Hypertac socket ensures the minimum temperature rise at high currents. Peak temperature of insulator material is normally the primary limiting factor in demanding conditions. Materials used in Smiths Interconnect connectors are chosen to support the widest ambient temperature range (from -55°C to 125°C) and withstand temperature peaks during assembly, even those generated during vapor phase soldering. The shape of the contact sleeve formed by contact wires hyperbolically arranged around the pin provides a number of linear contact paths and offers immunity to shock and vibration.

Intercompact from Smiths Interconnect features insulators in proprietary Liquid Cristal Polymer material and hyperboloid contact technology for an optimized insulation resistance in severe environment conditions. The very low contact resistance of the Hypertac socket ensures the minimum temperature rise at high currents. Peak temperature of insulator material is normally the primary limiting factor in demanding conditions. Materials used in Smiths Interconnect connectors are chosen to support the widest ambient temperature range (from -55°C to 125°C) and withstand temperature peaks during assembly, even those generated during vapor phase soldering. The shape of the contact sleeve formed by contact wires hyperbolically arranged around the pin provides a number of linear contact paths and offers immunity to shock and vibration.

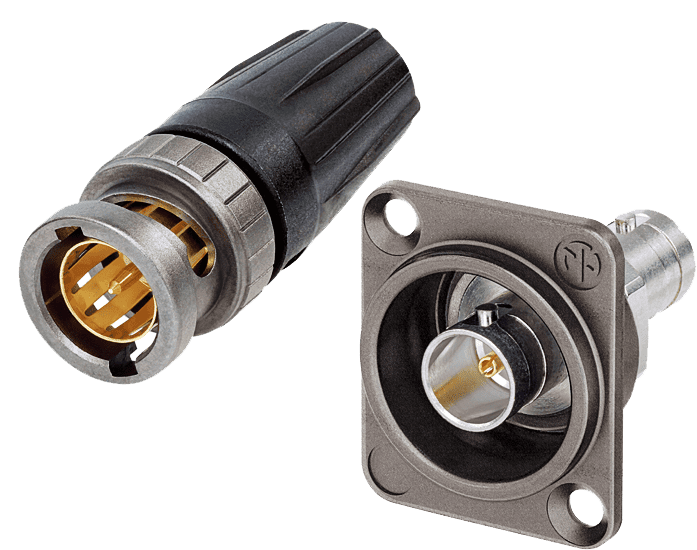

Neutrik’s UHD BNC 75-ohm cable and chassis connectors feature antraloy plating, a Swiss process with excellent durability and aesthetics. The rear TWIST UHD BNC connectors are specifically designed for high-resolution video signal transmissions. Due to the unique insulator and contact pin design, the connectors feature low return loss values for 4K and 8K signals and offer additional return loss reserve for potential impedance deviations resulting from cable bending, incorrect connector assembly, or faulty connection interfaces without signal interruption. They are fully compatible with conventional BNC chassis connectors.

Neutrik’s UHD BNC 75-ohm cable and chassis connectors feature antraloy plating, a Swiss process with excellent durability and aesthetics. The rear TWIST UHD BNC connectors are specifically designed for high-resolution video signal transmissions. Due to the unique insulator and contact pin design, the connectors feature low return loss values for 4K and 8K signals and offer additional return loss reserve for potential impedance deviations resulting from cable bending, incorrect connector assembly, or faulty connection interfaces without signal interruption. They are fully compatible with conventional BNC chassis connectors.

Amphenol ICC’s BarKlip BK150 connector comes with AGT plated contacts to provide lower resistance at a lower cost. AGT is one of two silver-based plating technologies developed by Amphenol that offer between a 10% and 20% increase in current-carrying capacity compared with the same products that are plated with either gold or GF-pdNi. Amphenol ICC offers several plating technologies, including GXT, a plating alternative to gold, and GCS and AGT silver plating solutions.

Amphenol ICC’s BarKlip BK150 connector comes with AGT plated contacts to provide lower resistance at a lower cost. AGT is one of two silver-based plating technologies developed by Amphenol that offer between a 10% and 20% increase in current-carrying capacity compared with the same products that are plated with either gold or GF-pdNi. Amphenol ICC offers several plating technologies, including GXT, a plating alternative to gold, and GCS and AGT silver plating solutions.

SOS Engineering has developed new selective plating techniques that allow you to specify the plated areas. Selective gold plating has become a cost-effective way to plate electrical contacts because it limits gold use without reducing the functionality or performance of the connector. With selective plating, gold is only applied to the critical areas on the contact that require additional material to meet performance requirements. Previously, the M39029 specification required .000050” of gold plating over the entire outer surface of the contact. The specification now allows for selective gold plating, providing significant cost savings for M39029 connectors. Selective plating methods vary depending on desired contact characteristics, but primarily employ electroplating processes. Selective plating techniques include spot plating, stripe plating, brush plating, controlled depth plating, and vibratory barrel plating. Depending on the size of the contact, these selective plating techniques can save up to 50% of gold plating costs.

SOS Engineering has developed new selective plating techniques that allow you to specify the plated areas. Selective gold plating has become a cost-effective way to plate electrical contacts because it limits gold use without reducing the functionality or performance of the connector. With selective plating, gold is only applied to the critical areas on the contact that require additional material to meet performance requirements. Previously, the M39029 specification required .000050” of gold plating over the entire outer surface of the contact. The specification now allows for selective gold plating, providing significant cost savings for M39029 connectors. Selective plating methods vary depending on desired contact characteristics, but primarily employ electroplating processes. Selective plating techniques include spot plating, stripe plating, brush plating, controlled depth plating, and vibratory barrel plating. Depending on the size of the contact, these selective plating techniques can save up to 50% of gold plating costs.

Han-Eco from HARTING includes a range of hoods and housings made of high-performance plastic. Due to their resistance to environmental impacts, the hoods and housings are suitable for both indoor and outdoor applications. The use of plastic also brings significant weight and cost advantages over metal hoods and housings. A wide range of Han-Modular modules can be directly inserted into the hoods and housings of Han-Eco Modular connectors without screws and tools. The installation is based on a simple and reliable locking solution called “Click & Mate.” This creates new possibilities for plastic hoods and housings used in indoor and outdoor applications. Compared to the equivalent counterparts within the Han B standard, each hood/housing of the four standard sizes of Han-Eco Modular offers enough space for one more module.

Han-Eco from HARTING includes a range of hoods and housings made of high-performance plastic. Due to their resistance to environmental impacts, the hoods and housings are suitable for both indoor and outdoor applications. The use of plastic also brings significant weight and cost advantages over metal hoods and housings. A wide range of Han-Modular modules can be directly inserted into the hoods and housings of Han-Eco Modular connectors without screws and tools. The installation is based on a simple and reliable locking solution called “Click & Mate.” This creates new possibilities for plastic hoods and housings used in indoor and outdoor applications. Compared to the equivalent counterparts within the Han B standard, each hood/housing of the four standard sizes of Han-Eco Modular offers enough space for one more module.

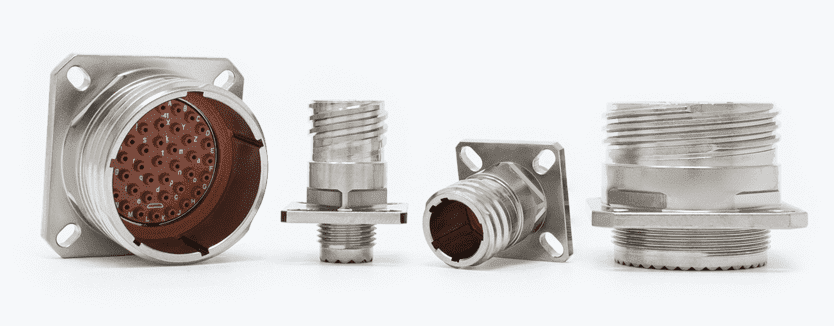

AP-93 from Amphenol Aerospace is a conductive REACH/RoHS-compliant finish that outperforms cadmium olive-drab cadmium plating (Class W) with 1,000 hours of dynamic salt spray and 500 mating cycles, as well as meeting the millivolt drop shell-to-shell conductivity of nickel (Class F). AP-93 also meets a 200°C temperature rating, is compatible with other platings, and is available on all D38999-style Series III connectors. AP-93 is intermateable with cadmium, making it the perfect drop-in replacement for applications where cadmium has been the preferred option. With its superior barrier protection and excellent lubricity for threaded applications, AP-93 is an excellent choice for harsh applications related to sea, air, weapons systems, and space systems.

AP-93 from Amphenol Aerospace is a conductive REACH/RoHS-compliant finish that outperforms cadmium olive-drab cadmium plating (Class W) with 1,000 hours of dynamic salt spray and 500 mating cycles, as well as meeting the millivolt drop shell-to-shell conductivity of nickel (Class F). AP-93 also meets a 200°C temperature rating, is compatible with other platings, and is available on all D38999-style Series III connectors. AP-93 is intermateable with cadmium, making it the perfect drop-in replacement for applications where cadmium has been the preferred option. With its superior barrier protection and excellent lubricity for threaded applications, AP-93 is an excellent choice for harsh applications related to sea, air, weapons systems, and space systems.

Robust outdoor housings from Phoenix Contact’s ECS series are the ideal solution for protecting sensitive electronics used in indoor and outdoor applications from dust, dirt, and water. Thanks to IP67 and IP69 degrees of protection and a wide temperature range from -40°C to 100°C, the housings are ideal for challenging ambient conditions. The ECS housing design supports a range of PCB thicknesses. Proven PCB connection technology permits practical customization. Integrated interlock protects against unintentional release of the PCB. Optional pressure compensation membrane is available for vented housing designs. A simple seal protects against tampering. The robust ECS electronics housings are ideal for wall and mast mounting and permit easy integration of PCBs with a thickness of 1.59 mm and 2.38 mm.

Robust outdoor housings from Phoenix Contact’s ECS series are the ideal solution for protecting sensitive electronics used in indoor and outdoor applications from dust, dirt, and water. Thanks to IP67 and IP69 degrees of protection and a wide temperature range from -40°C to 100°C, the housings are ideal for challenging ambient conditions. The ECS housing design supports a range of PCB thicknesses. Proven PCB connection technology permits practical customization. Integrated interlock protects against unintentional release of the PCB. Optional pressure compensation membrane is available for vented housing designs. A simple seal protects against tampering. The robust ECS electronics housings are ideal for wall and mast mounting and permit easy integration of PCBs with a thickness of 1.59 mm and 2.38 mm.

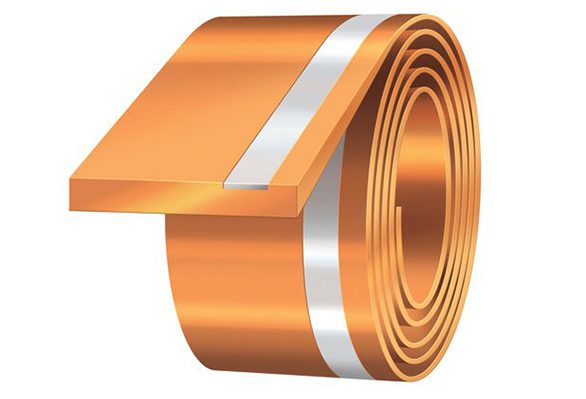

Materion’s iON EV Clad was engineered to be a drop-in replacement for the pure silver often used in electric vehicle charger connections. It was specifically designed to have low insertion friction/force, outstanding wear characteristics, and high electrical conductivity. iON EV clad offers improved performance and the ability to withstand the high energy environment of fast charge connectors.

Materion’s iON EV Clad was engineered to be a drop-in replacement for the pure silver often used in electric vehicle charger connections. It was specifically designed to have low insertion friction/force, outstanding wear characteristics, and high electrical conductivity. iON EV clad offers improved performance and the ability to withstand the high energy environment of fast charge connectors.

Meco SFRS technology can plate two sides only on miniature connectors with a pitch as small as 1.8 mm. With selective plating, metal consumption is substantially reduced by plating front and rear sides only on (semi) rectangular connectors. Achievable metal reductions versus controlled depth plating are 45%.

Meco SFRS technology can plate two sides only on miniature connectors with a pitch as small as 1.8 mm. With selective plating, metal consumption is substantially reduced by plating front and rear sides only on (semi) rectangular connectors. Achievable metal reductions versus controlled depth plating are 45%.

Learn more from these recent materials-focused products roundups: Overmolded Cable Assemblies, Low-Smoke, Zero Halogen Cable Assemblies, and EMI/RFI Shielded Connectors.

Like this article? Check out our other Product Roundup, Product News, and Connector Industry News features and our 2022 and 2021 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Mezzanine Connectors Product Roundup - April 16, 2024

- Out Now! New eBook Shares Bright Ideas for Electrification - April 16, 2024

- What are ARINC 801 Connectors? - April 9, 2024