Overmolded Cable Assemblies Product Roundup II

This week’s Product Roundup highlights overmolded cable assemblies from leading suppliers.

Overmolded Cable Assemblies

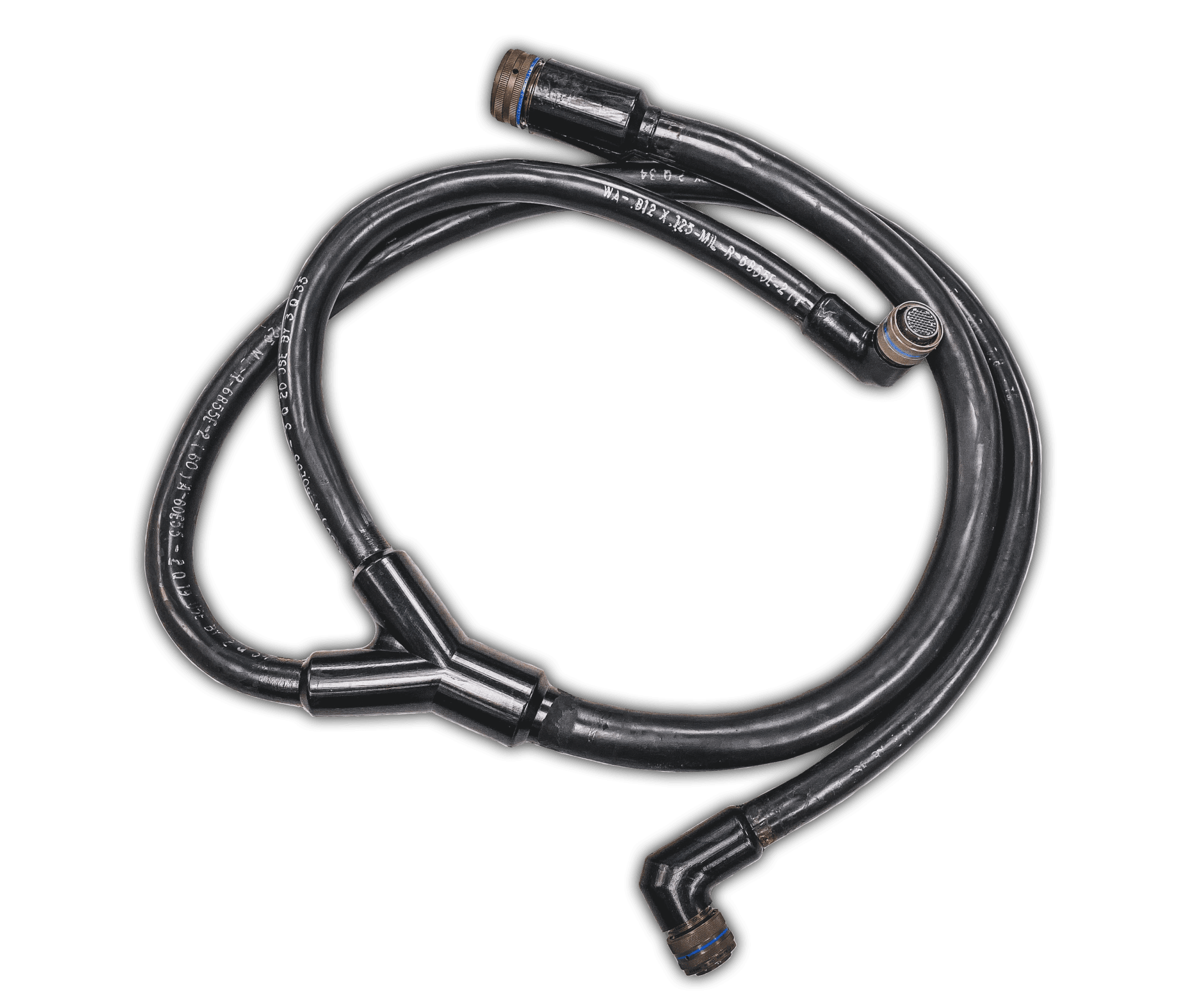

CDM now includes the overmolding process in its suite of value-added production capabilities for its connector and cable assemblies. Overmolding can form a solid strain-relieving seal over the junction and entire connector to allow for easier or more rigorous handling of the connector especially when mating. Generally, this process addresses all commercial, industrial, military, and agricultural interconnects exposed to a harsh environment or repeated mating/unmating cycles. Specific applications include intermediate and light duty power cable assemblies for industrial, medical, and military equipment; RF / coaxial cable assemblies; military/tactical communications cable assemblies; rugged-use or specialty Ethernet cable assemblies; wiring harnesses; D-sub and other mini connector cable assemblies; and telecommunications cable. Overmold plastics are available in a variety of colors and materials including polypropylene, polyethylene, TPUs, TPEs, and SantopreneTM. With 7.5 cubic-inch, 5-oz single shot capacity, it can accommodate a molded form up to 5” x 5” x 3”. Currently, CDM can manufacture up to 1,000 overmolded pieces per month, with the ability to ramp up capacity based on customer requirements. This is a 100% U.S. program, with all planning and manufacturing in CDM’s New Jersey facilities.

CDM now includes the overmolding process in its suite of value-added production capabilities for its connector and cable assemblies. Overmolding can form a solid strain-relieving seal over the junction and entire connector to allow for easier or more rigorous handling of the connector especially when mating. Generally, this process addresses all commercial, industrial, military, and agricultural interconnects exposed to a harsh environment or repeated mating/unmating cycles. Specific applications include intermediate and light duty power cable assemblies for industrial, medical, and military equipment; RF / coaxial cable assemblies; military/tactical communications cable assemblies; rugged-use or specialty Ethernet cable assemblies; wiring harnesses; D-sub and other mini connector cable assemblies; and telecommunications cable. Overmold plastics are available in a variety of colors and materials including polypropylene, polyethylene, TPUs, TPEs, and SantopreneTM. With 7.5 cubic-inch, 5-oz single shot capacity, it can accommodate a molded form up to 5” x 5” x 3”. Currently, CDM can manufacture up to 1,000 overmolded pieces per month, with the ability to ramp up capacity based on customer requirements. This is a 100% U.S. program, with all planning and manufacturing in CDM’s New Jersey facilities.

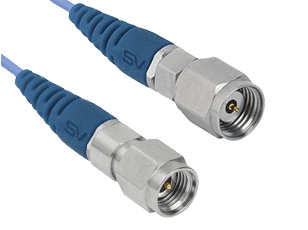

SV Microwave’s new line of strain relief cable assemblies features an overmolded boot to protect the sensitive cable termination area and allow for more flexibility and peace of mind. Now available with male interfaces in the SMA, 2.92 mm, 2.4 mm, or 1.85 mm connector series. These cable assemblies are ideal for test and instrumentation applications as well as harsh environments.

SV Microwave’s new line of strain relief cable assemblies features an overmolded boot to protect the sensitive cable termination area and allow for more flexibility and peace of mind. Now available with male interfaces in the SMA, 2.92 mm, 2.4 mm, or 1.85 mm connector series. These cable assemblies are ideal for test and instrumentation applications as well as harsh environments.

Weidmüller offers an extensive range of prefabricated cables, as well as an online configurator to create individual signal cord sets for sensors or data cord sets for Ethernet. Various individualization levels meet the needs in every planning situation. Overmolded versions are available. Demand-oriented cable lengths, plugs, markings, or colors are available from a batch size of one. Weidmüller cables are compatible for use in robots and are available with recyclable, halogen-free cables.

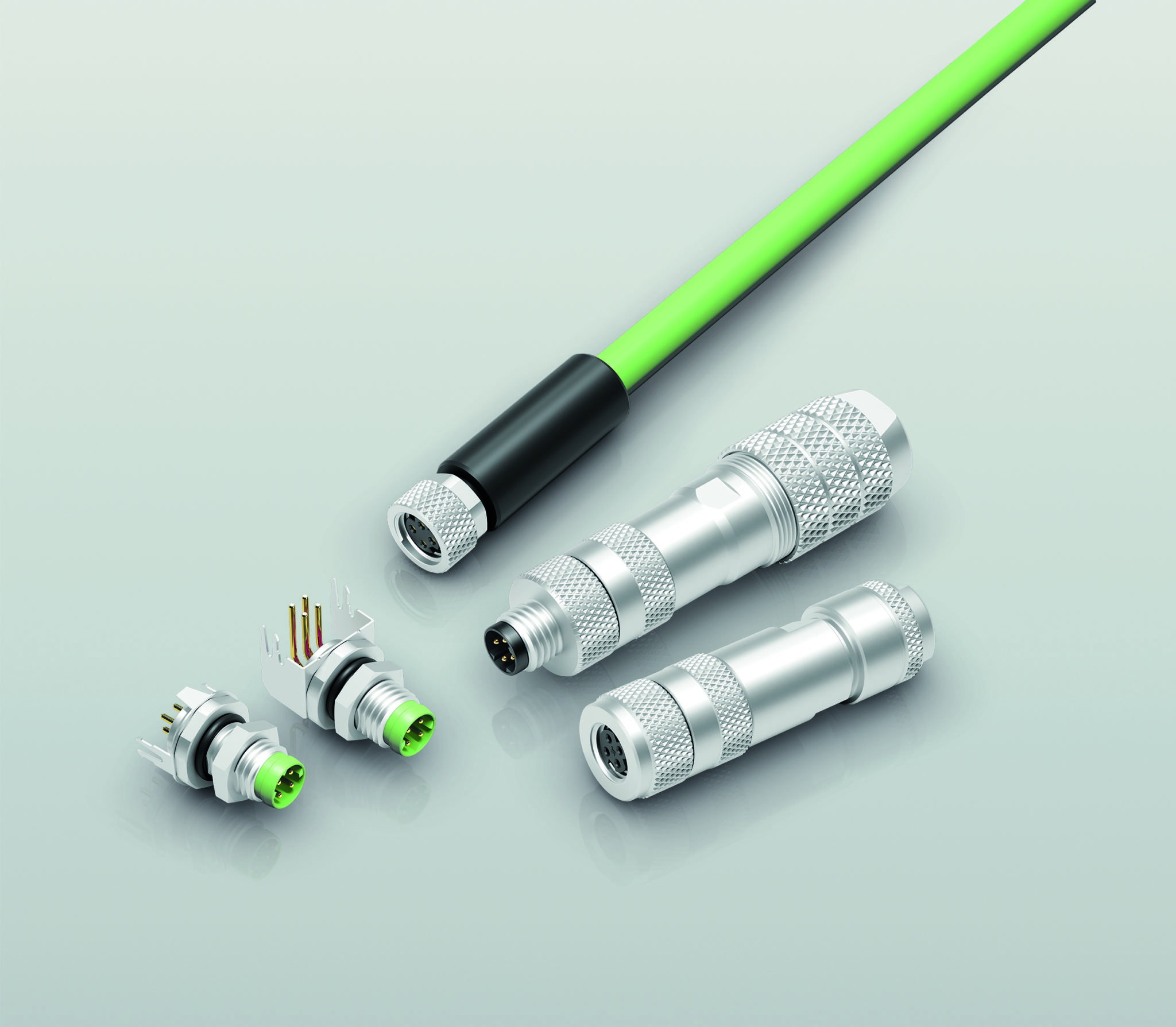

Binder’s M8 connectors with D-coding of the 818 series according to DIN EN 61076-2-114 are designed for secure Ethernet data transmission up to 100 Mb/s in the network. They have 360° shielding and comply with protection class IP67, have four contacts, and are available as straight cable connectors and as straight and angled flange connectors. The cable connectors that can be assembled have screw terminals, and the flange connectors have dip solder terminals and shielding plate. Featuring overmolded and shielded or screw termination, the 4-pin D-coded M8 connectors are equipped with gold-plated and symmetrically arranged contacts and are designed for more than 100 mating cycles. A rated voltage of 63 V(DC), a rated current of 4 A, and a rated surge voltage of 1500 V are specified for the products. The operating temperature range extends from -25 °C to +85 °C (idle state).

Binder’s M8 connectors with D-coding of the 818 series according to DIN EN 61076-2-114 are designed for secure Ethernet data transmission up to 100 Mb/s in the network. They have 360° shielding and comply with protection class IP67, have four contacts, and are available as straight cable connectors and as straight and angled flange connectors. The cable connectors that can be assembled have screw terminals, and the flange connectors have dip solder terminals and shielding plate. Featuring overmolded and shielded or screw termination, the 4-pin D-coded M8 connectors are equipped with gold-plated and symmetrically arranged contacts and are designed for more than 100 mating cycles. A rated voltage of 63 V(DC), a rated current of 4 A, and a rated surge voltage of 1500 V are specified for the products. The operating temperature range extends from -25 °C to +85 °C (idle state).

Axon’ Cable designs and manufactures overmolded cable assemblies for harsh environments. For medical applications, the cable and the overmolding are made to withstand the sterilization process. For marine applications, they are designed to withstand high pressure. Overmolding provides robust and tailor-made mechanical protection for the cable/connector interface which is traditionally the weakest point of cable assemblies. The process of overmolding involves joining together a set of parts while guaranteeing mechanical integrity and providing resistance to a variety of conditions such as abrasion, shock, radiation, chemicals, temperature, and moisture ingress. The adhesion effect highly depends on the compatibility of the materials chosen. Learn more about Axon’s expertise in overmolded cable assemblies.

Axon’ Cable designs and manufactures overmolded cable assemblies for harsh environments. For medical applications, the cable and the overmolding are made to withstand the sterilization process. For marine applications, they are designed to withstand high pressure. Overmolding provides robust and tailor-made mechanical protection for the cable/connector interface which is traditionally the weakest point of cable assemblies. The process of overmolding involves joining together a set of parts while guaranteeing mechanical integrity and providing resistance to a variety of conditions such as abrasion, shock, radiation, chemicals, temperature, and moisture ingress. The adhesion effect highly depends on the compatibility of the materials chosen. Learn more about Axon’s expertise in overmolded cable assemblies.

DX07 Series connectors from JAE are compatible with the next-generation USB specification “USB Type-C” and with Universal Serial Bus Type-C Specification Release 2.0, USB Power Delivery 3.0, and SuperSpeed USB 10 Gb/s communication (USB 3.2 Gen2). The DX07 Series supports 100 W (5 A/20 V) maximum power supply (compatible with USB Power Delivery Standard Power Range). The reversible plug structure eliminates any concerns about the plug orientation. These connectors demonstrate superior EMI/ EMC characteristics. They feature a lock structure with superior durability and are available with a screw lock for securely fixing to the device housing. (The screw lock attachment dimensions conform to the screw lock USB Type-C standard.)

DX07 Series connectors from JAE are compatible with the next-generation USB specification “USB Type-C” and with Universal Serial Bus Type-C Specification Release 2.0, USB Power Delivery 3.0, and SuperSpeed USB 10 Gb/s communication (USB 3.2 Gen2). The DX07 Series supports 100 W (5 A/20 V) maximum power supply (compatible with USB Power Delivery Standard Power Range). The reversible plug structure eliminates any concerns about the plug orientation. These connectors demonstrate superior EMI/ EMC characteristics. They feature a lock structure with superior durability and are available with a screw lock for securely fixing to the device housing. (The screw lock attachment dimensions conform to the screw lock USB Type-C standard.)

Phoenix Contacts M8, M12, and MINI 7/8” form factors have become an industry standard for robust and watertight quick-connect applications. Used primarily on sensors, actuators, instruments, and devices, these circular connectors are now an essential component on many industrial machines. M8 and M12 stocked product is made with 105 °C yellow PVC. M8 products are ideal for areas with space constraints or devices with the smaller M8 interconnect. The cable is sunlight resistant and is offered in both shielded and non-shielded variants. M12s with 18 or 22 AWG wires are PLTC (power limited tray cable)-rated, which allows easier cable routing according to NEC guidelines. Configurable cables are now available in black and gray PVC. The “Sweet Spot” model features overmolded solutions for M8 and M12.

Phoenix Contacts M8, M12, and MINI 7/8” form factors have become an industry standard for robust and watertight quick-connect applications. Used primarily on sensors, actuators, instruments, and devices, these circular connectors are now an essential component on many industrial machines. M8 and M12 stocked product is made with 105 °C yellow PVC. M8 products are ideal for areas with space constraints or devices with the smaller M8 interconnect. The cable is sunlight resistant and is offered in both shielded and non-shielded variants. M12s with 18 or 22 AWG wires are PLTC (power limited tray cable)-rated, which allows easier cable routing according to NEC guidelines. Configurable cables are now available in black and gray PVC. The “Sweet Spot” model features overmolded solutions for M8 and M12.

Northwire, a LEMO Group Company, offers overmold assemblies to meet the specific requirements of end applications for a variety of industries: medical, off-road heavy equipment, aerospace and defense, industrial, robotics, and more. As a design engineering, custom cable manufacturer, Northwire offers custom solutions for end applications that need low-pressure injection molding, 10-ton horizontal with vertical clamp high-pressure injection molding with four-ounce maximum shot size, strain-relief molding, or cable-to-connector overmolding.

Northwire, a LEMO Group Company, offers overmold assemblies to meet the specific requirements of end applications for a variety of industries: medical, off-road heavy equipment, aerospace and defense, industrial, robotics, and more. As a design engineering, custom cable manufacturer, Northwire offers custom solutions for end applications that need low-pressure injection molding, 10-ton horizontal with vertical clamp high-pressure injection molding with four-ounce maximum shot size, strain-relief molding, or cable-to-connector overmolding.

Omnetics Connector Corporation offers extensive overmolding design and manufacturing capabilities, typically provided for Omnetics’ own standard or custom-designed connectors, and value-added molds such as strain reliefs, grommets, and yokes. Omnetics’ expertise extends to customers in the medical, defense, aerospace, electronics, and other industries with design criteria such as biocompatibility (USP Class VI/ISO10993) for extended skin contact, high-strength and long flex life characteristics, halogen and flame-free UL 94 materials, tight tolerances (down to .002” in certain cases), all thicknesses as low as .010” for select applications, selective material bonding for water-resistant applications, and product identification or improved aesthetics of a connector assembly. Omnetics has many high-performance material options in-stock and can help customers identify the proper material for their application.

Omnetics Connector Corporation offers extensive overmolding design and manufacturing capabilities, typically provided for Omnetics’ own standard or custom-designed connectors, and value-added molds such as strain reliefs, grommets, and yokes. Omnetics’ expertise extends to customers in the medical, defense, aerospace, electronics, and other industries with design criteria such as biocompatibility (USP Class VI/ISO10993) for extended skin contact, high-strength and long flex life characteristics, halogen and flame-free UL 94 materials, tight tolerances (down to .002” in certain cases), all thicknesses as low as .010” for select applications, selective material bonding for water-resistant applications, and product identification or improved aesthetics of a connector assembly. Omnetics has many high-performance material options in-stock and can help customers identify the proper material for their application.

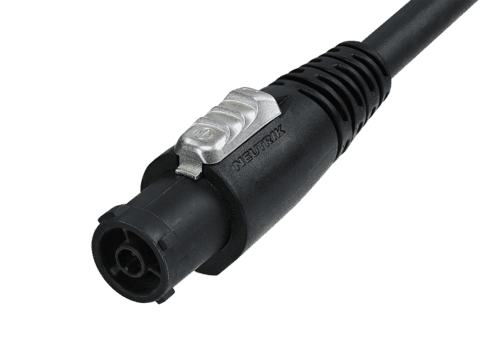

Neutrik’s powerCON TRUE1 Power Cord is a ready-made overmolded power cord in protection class IP65. The cable utilizes standard duty cord with three conductors with cross section 1.5 mm2 or AWG 12. The cables are equipped with overmolded Neutrik powerCON TRUE1 NAC3FX-W or NAC3MX-W. The other end is open for termination of local connectors. Overmolded local connectors are available on request. The cables are available in different lengths.

Neutrik’s powerCON TRUE1 Power Cord is a ready-made overmolded power cord in protection class IP65. The cable utilizes standard duty cord with three conductors with cross section 1.5 mm2 or AWG 12. The cables are equipped with overmolded Neutrik powerCON TRUE1 NAC3FX-W or NAC3MX-W. The other end is open for termination of local connectors. Overmolded local connectors are available on request. The cables are available in different lengths.

TTI Inc. now supplies the full range of Off-the-Shelf (OTS) Single Row Micro-Fit Overmolded Cable Assemblies. These cable assemblies complement TTI’s range of single row, micro-fit discrete products and allow designers and engineers to try out an assembly and ensure it works before ordering the perfect custom-length product assembly for a new design. Applications include consumer and industrial.

TTI Inc. now supplies the full range of Off-the-Shelf (OTS) Single Row Micro-Fit Overmolded Cable Assemblies. These cable assemblies complement TTI’s range of single row, micro-fit discrete products and allow designers and engineers to try out an assembly and ensure it works before ordering the perfect custom-length product assembly for a new design. Applications include consumer and industrial.

Dive deeper into cable assemblies with these previously published product roundups: Space Grade Connectors and Cable Assemblies, Fiber Optic Connectors & Cable Assemblies, and Hybrid Cable Assemblies with Copper & Fiber Conductors.

Like this article? Check out our other Product Roundup, Product News, and Connector Industry News features and our 2022 and 2021 Article Archives.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024