What to Consider When Selecting IoT Connectors

Selecting the right connector for IoT applications is critical, not only in terms of delivering reliability and performance but also for keeping the footprint of IoT sensors and nodes to an absolute minimum.

Experts on the Internet of Things (IoT) believe that the technology can only reach its full potential if it is based on wireless communications. Although a huge number IoT nodes are battery-powered and connected wirelessly, IoT systems benefit significantly from the use of sensors that are connected via cables. Many connectors are well suited to IoT applications but designers searching for the best IoT connectors look for differentiating factors — what makes a product unique, what benefits it provides, and if the supplier has extensive knowledge of the product and can support it in applications.

Why the future isn’t all wireless

The focus for IoT connectors is primarily on wireless sensors but the reality is that hardwired connectors are vitally important components within many IoT systems. Companies such as Newark offer an extensive range of connector solutions for these applications, particularly small connectors that are ideal for fitting to IoT sensors and nodes.

Hardwired connections can be preferable for many reasons. For example, wired networking often provides far more resilience and robustness in electrically noisy environments where reliable communications are essential without any interference. Similarly, in harsh environments it makes sense to make use of industrial Ethernet connectors that perform far better than wireless technology, including IP-rated connectors that protect against the ingress of water, dust, and other elements. In such applications, IoT connectors need compact form factors to minimize the circuit board real estate; standard RJ45 connectors are usually too large.

Examples of IoT-friendly connectors include HARTING’s RJ45 Industrial Ethernet data interfaces that incorporate features such as intuitive locking mechanisms, tool-free fast connection, and thermoplastic or metal hoods and housings. Offering data transmission speeds of up to 10 Gb/s, these connectors tend to be rated to IP20, IP54, IP65, and IP67, while some also provide 4 x 48V/16A or 3 x 300V/16A.

HARTING’s ix Industrial family of Ethernet interfaces offers a miniaturized alternative to the RJ45 (requiring 70% less space). Referred to as a “small giant” for IoT applications, the ix Industrial family consists of robust plug-in connectors that can produce Cat6A performance for 1 Gb/s to 10 Gb/s Ethernet. Ideal for harsh industrial environments, the units ensure safe data transmission with high EMC immunity.

Some IoT applications require connectors that incorporate USB connections. TE Connectivity’s universal connectors provide bi-directional, simultaneous signals for full speed (12 Mb/s) or low speed (1.5 Mb/s) used in USB systems. Easy to install, TE’s systems comprise a single, four-position board-mount receptacle (BMR) and mating cable mount overmolded plug. For flexibility and versatility in all types of USB applications, BMRs are available in standard, Type B, stacked, and side-by-side configurations. While Type-C USB connectors are small enough for use in mobile phones, micro USB 2.0 connectors are the smallest connectors of their kind that are capable of reliable and robust delivery of high-speed data. For transferring data 10 times faster than USB 2.0, design engineers can choose from a range of USB 3.0 connectors which support a data transfer rate of up to 5 Gb/s.

Another reason for using hard-wired sensors would be to meet the radio frequency (RF) challenges of environments such as noisy industrial installations. Although many IoT applications will not use external antennas, they can often prove ideal in difficult RF environments where more reliable communications are required than could be provided by wireless sensors.

Even though Wi-Fi, Bluetooth, and Zigbee cannot provide trouble-free connections over long distances, these technologies can enable fast and easy RF integration into connected systems, making them ideal for helping compact devices provide high-performance internet and data connectivity. For example, Molex offers 2.4 GHz/5 GHz and 900 MHz ultra-thin ceramic and LDS/MID IoT antennas alongside their associated connectors. Molex also offers complete RF solutions for high frequency performance while delivering superior signal integrity, even in extremely demanding environments. Available in ultra-microminiature format (with a profile as low as 1.8 mm) as well as larger RF units, Molex’s coaxial connectors and cable assemblies operate across a range of frequencies – from DC to 65 GHz.

Available in ultra-microminiature format (with a profile as low as 1.8 mm) as well as larger RF units, Molex’s coaxial connectors and cable assemblies operate across a range of frequencies – from DC to 65 GHz.

Different connectors for different needs

Memory connectors

Although soldering memory directly to a board will minimize space, it can also limit flexibility. Many engineers choose memory modules, allowing them to expand the available memory should they need additional processing or other options. Both Molex and TE Connectivity offer excellent solutions in this area, with ranges of memory connectors and custom memory modules for server, storage, and communication applications.

Board-to-board connectors

Often, designers of IoT systems stack boards to allow flexibility, such as connecting different sensors to a standard communications board. The free height board-to-board connectors produced by TE Connectivity are designed for parallel board stacking. Ideal for downsizing applications, these versatile units use sub-miniature connectors.

The free height connectors offer a range of position sizes, from 40 to 440 positions in contact pitches of 0.5 mm, 0.6 mm, 0.8 mm, and 1 mm. By mating various combinations of vertical plug and receptacle housing heights, board-to-board stack heights from 4 mm to 20 mm can be achieved in 1 mm increments. If further space savings are required, flexible board-to-board connections enable boards to be placed in any position to minimize a device’s footprint.

At the same time, flexible cable connectors can offer extremely high connection density combined with small pitch sizes. To meet the demand for smaller, more reliable connections, Molex has developed a range of low-profile/high-density interconnects with pitches from 0.2 mm to 2 mm and a dual-contact design.

Power and data connectors

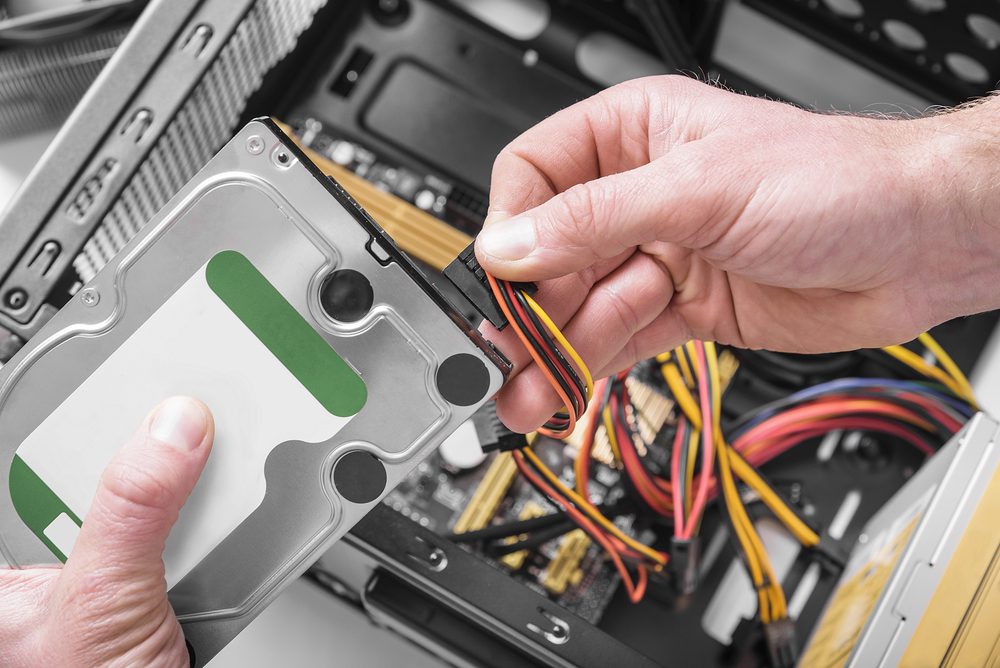

While some wireless sensors can deliver battery lives of up to 20 years, for many IoT applications, particularly in the Industrial Internet of Things (IIoT), powering devices through cables can remove the burden of replacing batteries. Being hardwired also enables designers to incorporate higher-power processors and peripherals into their schemes.

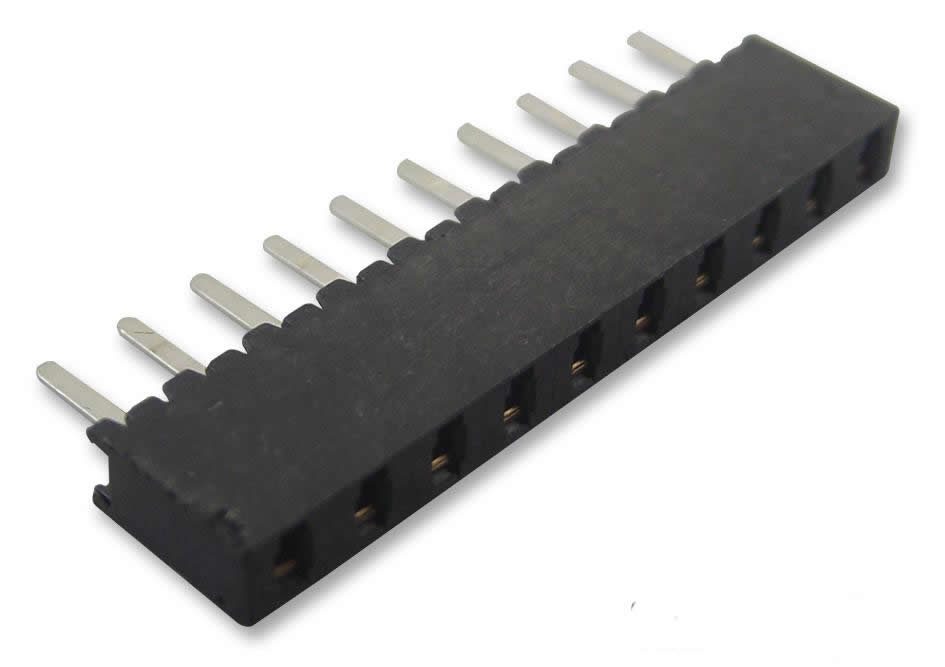

Samtec’s PCB receptacle, board-to-board, wire-to-board, 2 mm, 1 row, 10 contacts, through-hole mount, available at Farnell and Newark, Avnet companies.

Where power and data need to be combined, 2 mm connectors are a standard option. Samtec’s pitch sockets, headers, terminals, and board stackers, for example, are available in low-profile, elevated, and high-density designs to connect multiple boards together. Vertical and right-angle/horizontal orientations are available, as well as through-hole, surface mount, press-fit, and pass-through terminations.

If an IoT designer is looking for a more compact form factor than the more conventional 2 mm connectors, TE offers 1.5 mm AMP CT connectors that are miniature wire-to-board interconnect solutions, while Samtec offers 1.27 mm pitch board stacking socket and terminal strips. These rugged, low-cost products combine low profile with high-density and are available in various orientations and contact styles.

Ingress preventing connectors

Some IoT devices must be resistant to water or dust ingress. This requirement can be met with products such as HARTING’s lightweight Han industrial connector families, which can transmit both power and data, and are ideal for linking heating or cooling units, fans, control terminals, lighting systems, drives, and vibration conveyors. In outdoor installations, Han connectors offer protection against the ingress of dust and liquids up to IP65.

Configurable connectors

In the vast majority of IoT and IIoT applications, space is always a key factor. So, instead of working with standard off-the-shelf products that could include more contacts than required – and therefore take up space unnecessarily – it often makes sense to work with connectors that can be configured to meet the exact needs of an installation.

Reliability and cost are key

Reliability and cost are key criteria for connector selection. TE Connectivity’s cost-conscious FASTON quick-connect line includes low insertion force terminals, high temperature units, and low-profile terminals. Available in insulated and uninsulated versions, straight and flag configurations, and with various plating options, the terminals feature stress-relieved receptacles with positive lock for easy installation and secure retention.

There is still a significant market for wired connectors for IoT systems and installations. Small, reliable, powerful, robust, and battery-free – those are the benefits offered by hardware-based connectivity systems.

Visit Newark to learn more.

Find this article and more expert insights on connectivity components in our new eBook Connectivity Components: Everything but Complete Connectors, available for free download now.

Find this article and more expert insights on connectivity components in our new eBook Connectivity Components: Everything but Complete Connectors, available for free download now.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- What to Consider When Selecting IoT Connectors - September 14, 2021

- Why You Can No Longer Ignore Connectors - May 21, 2019