What are MIL-DTL-83513 connectors?

Meet the Connector: MIL-DTL-83513

MIL-DTL-83515 specifies the requirements for micro-D connectors used in military applications.

MIL-DTL-83513 is a detailed specification controlling dimensions, materials, performance, and testing of plastic and metal shell micro-D connectors. This specification applies to micro-D connectors used in military applications, although because of their ruggedness, micro-Ds are also found in many industrial and other harsh environment applications, like geophysical and medical equipment.

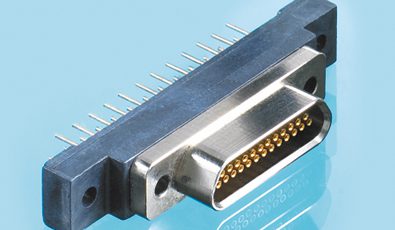

Size: Typically, these connectors are half the size of standard D-Subminiature connectors with contacts on .050 inch (1.3 mm) centers.

Layouts: Eight standard layouts (9, 15, 21, 25, 31, 37, 51, and 100 pin).

PCB termination: Straight printed circuit board, right angle printed circuit board, narrow profile right angle printed circuit board.

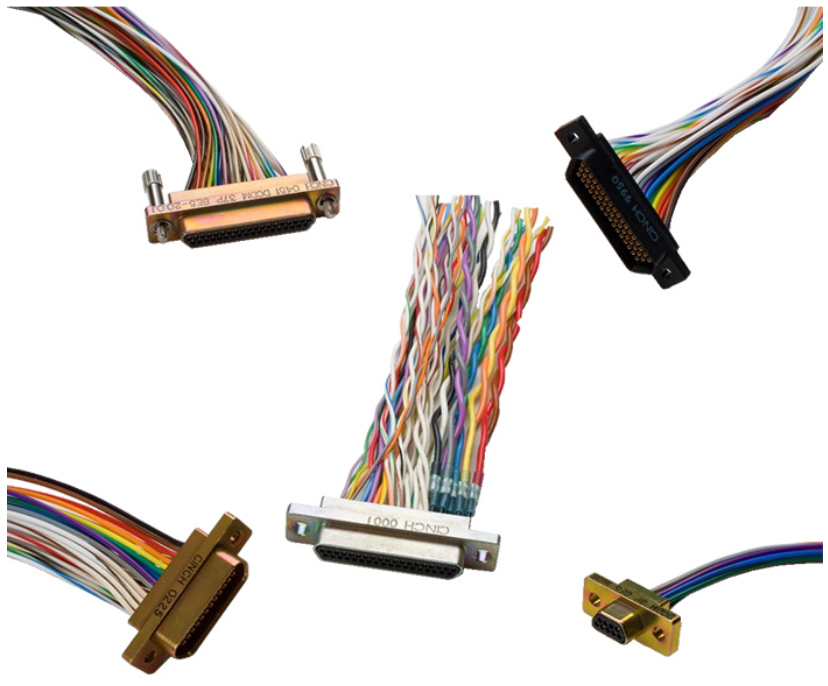

Wire termination: Products are available with pre-terminated insulated or uninsulated leads in a variety of wire colors and lengths based on customer specifications. They are also available in solder.

Axon’ Cable offers a complete range of QPL qualified micro-D connectors to MIL-DTL-83513 based on the highly reliable twist pin contact. By its design and performance this technology enables the system to meet the most severe requirements. Axon’ offers micro-D connectors plated with black zinc nickel in compliance with the RoHS Directive. This environmentally friendly plating offers the same electrical and physical characteristics as cadmium.

Some of the specifications outlined in MIL-DTL-83513

Shells: Die cast or extruded aluminum type A380 in accordance with ASTM B85, or bar stock aluminum in accordance with ASTM B 221, or aluminum alloy 2024 in accordance with SAE AMS-QQ-A-250/4 or 6061, in accordance with SAE AMS-QQ-A-200/8 or SAE AMS-QQ-A-250/11 or 7075 in accordance with SAE AMS-QQ-A-200/11 or SA

Finishes: Class M. Must withstand 48-hour salt spray.

A – Pure electrodeposited aluminum in accordance with MIL-DTL-83488, type II, color shall be nonreflective

C – Cadmium in accordance with SAE-AMS-QQ-P-416, type II, class 3. A suitable underplate is permissible for aluminum shells when cadmium plating is used.

K – Zinc nickel in accordance with ASTM B841 over a suitable underplate

N – Electroless nickel (space applications only) in accordance with SAE AMS2404, class 3 or 4, .0005 inch minimum thickness or ASTM B733, class 3 or 4, service code SC2 for space applications only.

P – Passivated stainless steel

T – Nickel fluorocarbon polymer, High phosphate nickel with fluorocarbon polymer additive over a suitable underplate. Color shall be non-reflective. Finishes shall withstand 48-hour salt spray.

Cinch Connectivity’s DURA-CON D-shaped micro-miniature rectangular connectors are designed for applications that require a rugged, high performance, densely compacted interconnect. They are ideal for applications where weight and space must be kept to a minimum while maintaining maximum reliability. The twist pin provides seven points of contact when mated. Qualified (QPL) to MIL-DTL-83513.

Temperature extremes: Low -55 °C +0, -3; High +125° C +3, -0

Interfacial seals: Made from silicone or fluorosilicone elastomer in accordance with A-A-59588 or SAE-AMS-R-25988.

Tin content: The use of pure tin is prohibited; tin content used in connector materials shall not exceed 97%. An alloy material must be chosen to inhibit the growth of tin whiskers.

Contacts: Nonremovable solder and crimp contacts. Contacts are either a unique twist pin or solid tube socket construction. The twist pin contact is constructed by welding seven wires together. Unlike regular D-sub contacts, pin contacts are housed inside the insulator to protect them from damage, while socket contacts extend from the socket insulator.

Shell polarization: Keystone shape shell design with polarization accomplished before engagement of the pins and sockets.

Mating and unmating force: The maximum force shall not exceed a value equal to 10 ounces times the number of contacts. Mating life is a minimum of 500 cycles.

Contact retention: Contacts for connectors shall be retained in the insulators by a 5-pound minimum force.

Dielectric withstanding voltage: Mated or unmated connectors shall show no evidence of breakdown or flashover when subjected to the test voltages and altitude. Corona shall not be considered.

Mouser supplies Glenair QPL Micro-D MIL-DTL-83513 connectors and hardware. They offer outstanding mating performance, durability, and minimal contact resistance. Micro-D connectors feature high-density micro TwistPin contacts set on 0.050 centers in arrangements from 9 to 130 contacts. They are available with insulated or uninsulated wire, PCB, solder cup, and flex terminations.

Markets/Applications: Military, aerospace, industrial, navigation and guidance systems, smart munitions, downhole equipment (oil & gas), medical equipment, geophysical equipment, and other harsh environment applications.

Suppliers: Many suppliers offer MIL-DTL-83513 connectors, including AirBorn, Axon’ Cable, Bel Cinch, ITT Cannon, Mouser Electronics , Nicomatic, Omnetics Connector Corporation, PEI-Genesis, TE Connectivity, BTC Electronics, Glenair, Hermetic Solutions Group, Newark.

Related products:

Like this article? Check out our other Meet the Connector, Mil-Spec Connectors, and our Transportation Market Page, and our 2022 and 2023 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024