What are MIL-DTL-26482 connectors?

What are MIL-DTL-26482 connectors?

Meet the Connector: MIL-DTL-26482 Connectors

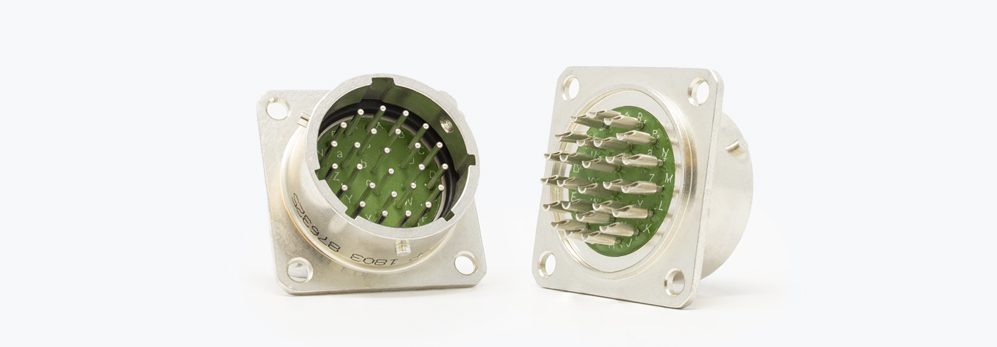

The MIL-DTL-26482 specification outlines the requirements for two series of miniature circular harsh environment connectors. These input-output (I/O) connectors are used to connect systems that require electrical power and signal, such as aircraft, ground vehicles, radar systems, shipboard applications, or mobile power-generation systems.

MIL-DTL-26482 (originally MIL-C-26482) was developed in the1950s when the military sought a derivative of the MIL-C-5015 for use with smaller gauge wire. “The 5015 was considered good technology in its time, but it used size 16-gauge contacts and larger. As things got a little bit more advanced in the electronics world, 18- and 20-gauge wire became available. The size 16 contacts in the 5015 family could handle it, but performance wasn’t as good,” said Scott Miller, director of product management at Cinch Connectivity Solutions.

Cinch Connectivity Solutions offers MS3110 through MS3129 and commercial versions of the MIL-DTL-26482 environmentally sealed circular connector. Available in threaded and bayonet coupling with solder, crimp, or pc tail contacts, and in PW, PWF, and PWC series commercial versions.

The 5015 circular Mil-spec is referred to as the standard product and the 26482 is the miniature product line. While 16 and 12 contact sizes are available with 26482, using 20-gauge contacts (one size down from the 5015), 26482 was more specific to the range of wires being developed at the time.

Much of the popularity around the MIL-DTL-26482 connector comes from its long-standing reputation for durability, reliability, and performance. “When engineers are designing a system that used 26482 in the previous generation, they’re going to stick with that 26482 most of the time because it’s tried and true and it’s a great value,” said Miller. “These connectors can be sitting in the middle of the worst environment in the world and can last for 15 to 20 years in the field.” Other connectors might be less expensive, but when factoring in the cost and difficulty of replacement, possibly multiple times in that same time frame, the 26482 typically comes out ahead in terms of cost.

TE Connectivity’s MIL-DTL-26482 Standard Series II bayonet connector is a miniature, circular with quick disconnect coupling. It is widely used in aerospace applications.

Design Notes

Commercial versions of MIL-DTL-26842 or those qualified to VG95328 may deviate from the official military specification.

ITT Cannon’s KPT miniature circular connector series is designed per MIL-DTL-26482 standards.

Standards: MIL-DTL-26482; MIL-STD-1669 provides insert arrangements

Series: Series I includes MS3110, MS3111, MS3112, MS3114 and MS3116 solder cup connectors and MS3120, MS3121, MS3122, MS3124, and MS3126 front release crimp contact connectors. Series II includes MS3470, MS3474, MS3475 and MS3476 rear release crimp contact connectors.

Environmental properties: Includes hermetic receptacles.

Temperature range: Classes E, F, J, and P connectors are used in environment-resisting applications with an operating temperature range of -55 to +125 °C.

Pressure: Class H receptacles are used when pressures must be contained across the walls or panels on which the connector is mounted.

Mounting types: Panel mount or inline receptacles

Mating: The two series of connectors are intermateable when using standard power and signal contacts, but not when using shielded contacts.

Contacts: Copper alloy

Plating: For the contacts, gold plating is required in MIL-spec versions (qualified to SAE AS39029 requirements). For the standard aluminum shell housings, options for the defense industry include olive drab cadmium, black zinc nickel, black anodized nickel, and electroless nickel. Olive drab cadmium offers the best combination of corrosion resistance and conductivity in harsh environments. Black zinc nickel is a suitable alternative for cadmium in terms of conductivity and corrosion resistance, while still eliminating the shiny finish. Electroless nickel plating has slightly less corrosion resistance but higher conductivity than cadmium.

Pins: Multiple options exist for number of pins and configuration.

Termination: Solder cup and crimp termination versions are available. They offer the same level of performance, but crimp termination offers better field serviceability, and may be preferred for extreme high vibration applications, e.g., rockets, satellites, and launching missiles.

Materials: Aluminum or stainless steel

Insulation: Neoprene

Locking mechanism: Threaded or bayonet coupling. Bayonet coupling provides a quick disconnect mechanism.

Deviations: Commercial and industrial versions of MIL-DTL-26482 may deviate from the official military specification.

Markets and Applications

Military, Aerospace, Industrial

Aircraft, ground vehicles, marine equipment, power generation and distribution, sensors and instrumentation, vacuum chambers, telecommunications, factory automation, traffic signal, oil and gas/energy, entertainment, rail/mass transit, heavy equipment, agricultural.

Suppliers

- Amphenol Aerospace

- Cinch Connectivity Solutions

- ITT Cannon

- PEI-Genesis

- Sealtron (AMETEK)

- TE Connectivity

- Glenair

- Souriau

- Newark

Related products

- MIL-DTL-5015 connectors

- MIL-DTL-83723 connectors

- MIL-DTL-38999 connectors

Like this article? Check out our other Meet the Connector and Circular Connectors articles, our Transportation Market Page, and our 2024 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- M-Type Connectors Product Roundup - May 14, 2024

- May 2024 Connector Industry News - May 14, 2024

- Testing is Vital for Electronics Performance and Reliability - May 7, 2024