The Digital, Automated Eye Exam

A new wave of optometry equipment relies on sensors, high-speed connectors, and the Internet of Things.

Until recently, a routine visit to the eye doctor included a series of tests conducted using mostly mechanical tools. The standard optometry devices have continually evolved since their historical origins, but upgrades have been incremental — modern lighting systems, new comfort and hygiene features, and updated physical designs. Today, though, new digital, sensor-rich, IoT-enabled equipment is coming into use, significantly improving diagnostics and the patient experience.

First, a walk through a traditional eye exam. The classic Snellen eye chart, published in 1862, remains in use around the world. Completely low-tech, in this test a patient simply reads a series of letters on the charts, which appear in descending sizes on a printed or projected surface. The ophthalmologist can ballpark a prescription based on the smallest line of characters the patient can decipher.

First, a walk through a traditional eye exam. The classic Snellen eye chart, published in 1862, remains in use around the world. Completely low-tech, in this test a patient simply reads a series of letters on the charts, which appear in descending sizes on a printed or projected surface. The ophthalmologist can ballpark a prescription based on the smallest line of characters the patient can decipher.

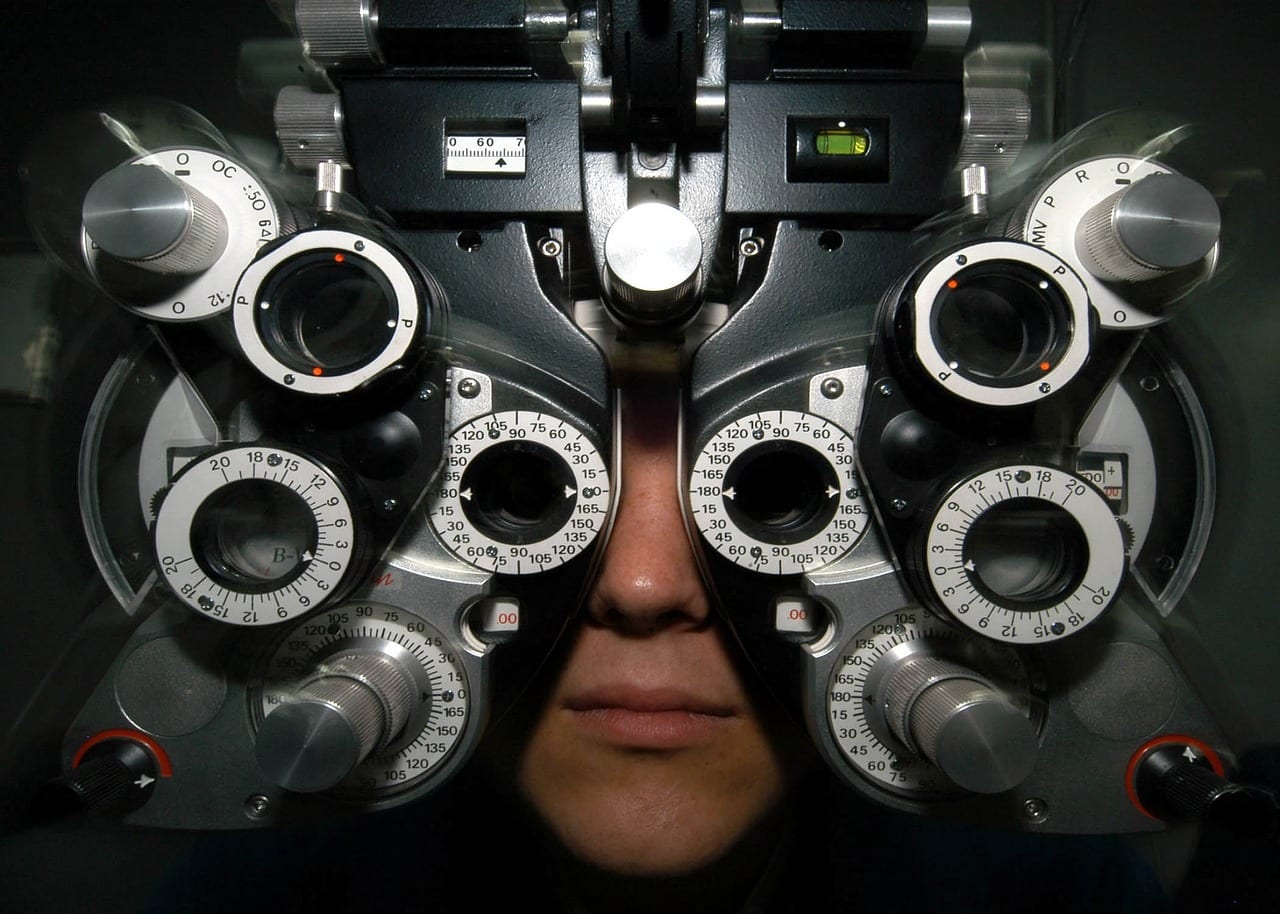

If the patient fails to achieve a 20/20 score on the reading test, they then sit behind a phoropter, also called a refractor. This device, which came into use in the early 1900s, contains a variety of lenses, which can be physically rotated or even swapped out for an expanded range. The patient reads the chart again through a series of magnifying lenses that simulate the experience of reading through a corrective lens. “Is this one better or is this one better?” the ophthalmologist asks, manually clicking between options to land on the most accurate prescription.

A keratometer

To assess the patient’s eye health, eye drops that dilate the pupils are applied, and then the eyes are viewed using a slit lamp microscope, keratometer, or a hand-held ophthalmoscope, devices that give the doctor a close-up view of the retina and interior structures in the eye.

These traditional optometry tools are rapidly being replaced by new digital, autonomous, and connected versions that depend on medical-grade electronics. LEDs, LCD screens, memory cards, and cameras are integrated into many diagnostic devices, which transmit that information to labs, patient record systems, and other, next-step diagnostic equipment.

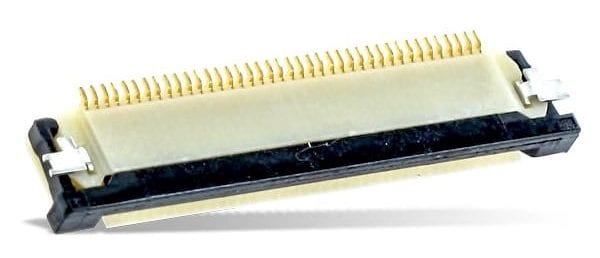

TE Connectivity’s Low-Profile FPC Connectors (Photo courtesy of Mouser Electronics)

“Professionals will have the choice of many more assessment, prevention and early intervention tools at their fingertips in the coming years,” said the authors of the Foresight Project Report, an assessment of optical technologies commissioned by the Optical Federation and the College of Optometrists in the UK. “The availability of this technology within community practice will in part be driven by market competition: an offering of the latest health technologies may well give a business the commercial edge over competitors.”

Electronics companies are supporting this evolution with a wide range of secure, high-speed, and scaled down connectors, sensors, and cable assemblies. Companies including TE Connectivity, Amphenol, Fischer, Omron, and Bel Power Solutions work closely with product designers to understand the goals of this highly specialized field of medicine.

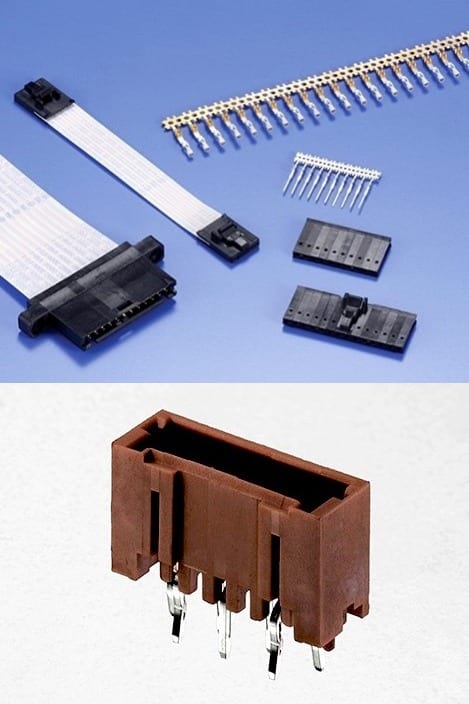

TE Connectivity’s Low Power Drawer connectors (TE Connectivity)

The components that empower this generation of optometry equipment typically don’t receive the rough handling, environmental conditions, and frequent disconnection that many other medical devices experience in daily practice. Yet they must endure frequent on-off cycles, withstand shock, resist materials wear and breakdown, deflect EMI, and preserve signal integrity. In some cases, portability is also a factor, as telemedicine and traveling care are becoming part of optometry practices. These scaled-down packages require smaller, compact components with secure connections.

TE Connectivity says the components used in optometry equipment include discrete wire connectors, flexible connectors, multimedia I/O connectors such as USBs and HDMIs, and antennae. They aren’t specific to the optometry world; components designed for medical and small devices are highly suitable to these applications.

New Equipment, Better Prescriptions

Now let’s take an eye exam conducted with the latest equipment. You may still read the classic Snellen eye chart, but it could be projected via a new digital visual acuity (VA) system. These software-driven eye charts can be randomized and customized, can test color vision, and can be adapted for pre-verbal or disabled patients. They are presented on a wall-hung in-plane-switching (IPS) panel display and controlled using an iOS device or even a gamepad. The information they collect is communicated to the clinic’s patient records system via Bluetooth.

Autorefractors are replacing manual refractors (i.e., phoropters).

What if you can’t read the 20/20 line? You’re in good company: Only 35% of adults can. On to the phoropter to determine your prescription. Except now it has been replaced by a new automated version called an autorefractor, or automated refractor. Sensors take over the role of the patient in the “This one or this one?” part of the eye exam. This machine uses sensors to measure how the eye responds to a cone of infrared light. The instrument automatically changes the magnification of an image until it comes into focus, a point determined by measuring the size and shape of a ring in the retina at the back of the eye. It can also measure cornea and pupil diameters.

TE Connectivity FFC and AMP connectors

Next, the doctor will examine the back of your eye. Instead of using eyedrops to dilate the pupil, many clinics are upgrading to retinal scanners, which require no dilation, a process some patients find uncomfortable and disruptive, as it can take several hours to return to normal. The new technology uses two lasers of different wavelengths and a mirror to take a scan of the back of the eye. Some scanners add a technique called fundus autofluorescence imaging to record chemical structures in the eye that fluoresce (or glow) in the presence of light of a certain wavelength. These machines allow doctors to take and store pictures of the eye, which can be used to track the progression of disease or anticipate problems.

Beyond the basic exam, a range of specialty equipment is undergoing the same digital transformation. From sensor-guided laser surgical tools to smart contact lenses embedded with microelectronic sensors, actuators, and components to transfer energy and data, the next wave of eye care will take advantage of recent developments in computing and IoT design.

Amphenol FCI FFC/FPC connector

In the meantime, better diagnostics, more precision prescriptions, faster and less invasive exams, and an visual historical record of eye health make the latest high-tech eye exam better than ever. Many clinics are now undergoing the upgrade process to stay competitive and correct their service to 20/20.

Interested in a specific market? Click a market below for current articles and news.

Automotive, Consumer, Industrial, Medical, Mil/Aero, Datacom/Telecom, and Transportation

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024