Smart, Rugged Connectors for the New Age of Agriculture Technologies

A new age of high-tech farming is changing the way our food is produced. Pest control using drones, embedded sensors that monitor soil conditions, and LED-lit indoor vertical farms all depend on rugged connectors for agricultural equipment.

Out of sheer frustration, many farmers are turning to new agricultural technologies such as drones for help fighting invasive species that have invaded crops or become resistant to mass application of chemicals. Programmed from the comfort of the farmer’s office, with accurate flight paths, speed, and altitude, ruggedized agricultural drones are being used to assess problems not readily visible from the ground and deliver strategic applications of biological pesticides.

The global robotic agricultural technologies market, which includes everything from unmanned aerial vehicles (drones), milking robots, driverless tractors, and automated harvesting systems, is slated to grow from $4.9 billion in 2021 to $11.9 billion by 2026. Water shortages, new climate and insect threats, and a global population that is expected to grow by another billion humans in the next 15 years will put incredible pressure on farmers to produce more food under increasingly challenging conditions. New agricultural technologies are helping to meet these challenges. Farmers are adapting, upgrading, and renewing their equipment to meet the needs of this new age of agriculture.

This equipment depends on powerful interconnects that can deliver the speed, power, and connectivity needed to communicate data across equipment. Connectors are responsible for everything from delivering power to equipment, connecting cameras to screens in tractor cabs, connecting sensors and transmitting the data they collect, to facilitating the connection between the tractor and its various harvesting attachments.

Ostrinia nubilalis, more commonly known as the European corn borer, is a grass moth of the family Crambidae that has a penchant for eating grain crops, especially corn. Measuring in at just 25 mm, the adult female corn borer has a light, yellowish brown complexion with dark wavy bands across its wings. Despite its diminutive size, it has been given the nickname billion-dollar bug because it has, in the past, cost farmers over a billion dollars of damage annually in the form of insecticide costs and lost crop yields.

Thanks to their multispectral imaging systems that allow them to capture footage in the near-infrared and visual spectrum, drones are ideal for identifying issues with irrigation, soil variation, and insect and fungal infestations. These images help farmers make informed decisions about treatments, ultimately increasing crop production.

Materials

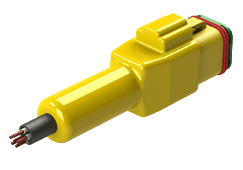

Rugged connectors for agricultural equipment must be able to handle harsh conditions, including ingress from water and debris, vibration and shock, UV exposure, and extreme hot and cold temperatures. However, the next generation of connectors will need to be more adaptable to meet the needs of automated equipment.

Take drone applications, for example. While a stainless-steel connector is commonly used in applications that require heat shielding, it’s too heavy for use in a drone. Conversely, connectors made from plastic or composites are light, strong, and immune from corrosion, but plastic can become brittle with prolonged use outdoors in direct sunlight.

Design engineers may instead specify aluminium connectors with an electroless nickel plating. This strong, durable, and lightweight material complements large implement connectors as well as the micro- or nano-miniature interconnects that drones or other small monitoring technologies need. This kind of balance will make rugged connectors for agricultural equipment more adaptable to the harsh environment conditions that agricultural technologies must endure.

Bandwidth

What goes inside the connector is just as critical as the choice of exterior material. With increased automation comes increased data transfer and electrical power demands. The next generation of rugged connectors for agricultural equipment will need high bandwidth fiber optic connections that can seamlessly transfer thousands of points of telemetry data and control signals from remote devices.

Quick connections

Another common issue is the ease with which connectors can be mated or disconnected. While a connector with a screw-type fitting allows a cable to be securely attached, it makes it much harder to connect or disconnect equipment when wearing gloves, especially in cold or rainy weather. Here, a bayonet or push-fit connector may be a better option for equipment that needs to be regularly swapped.

Platform flexibility

Because of the complexity that automation will bring to farming in the coming years, rugged connectors for agricultural equipment also need to offer flexibility for use across lighting and power systems, steering, and motion devices, as well as monitoring and control systems.

This is where modular connector assemblies may help to futureproof connector designs. Here, farmers can integrate many types of connectors into a single plate, allowing them to keep the same outer connector shell and housing, but swap out just the inserts when they need to update the type of cable or the pin configuration in a few years’ time. Combine this with a common ISOBUS platform — a type of serial communications protocol used for off-road, agricultural, and forestry equipment — and farmers will be able to use different equipment from different manufacturers interchangeably across tractors and towing vehicles.

Agricultural technologies are bringing about a new age of farming. Whether adopting new equipment comes out of sheer frustration at the likes of the billion-dollar bug, or comes along with a planned schedule of upgrades, a new generation of rugged connectors for agricultural equipment will help farmers rise to this challenge.

To learn more about connectivity solutions for agricultural technologies, visit PEI-Genesis.

Like this article? Check out our other ruggedized, harsh environment and automation articles, our Transportation Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Smart, Rugged Connectors for the New Age of Agriculture Technologies - August 23, 2022