Small-but-Mighty Connectors Play a Big Role in Rail Safety

Billions of electrical connections control various aspects of rail transportation, playing a significant role in global freight and passenger movements. New secure, easy-to-maintain connections help make railways safer.

Rail safety depends on multiple factors. Accidents result from human error and track defects, wheels and axles can break over time from heavy loads at high speeds, and journal bearings can overheat — as happened right before the train derailment in East Palestine, Ohio. More than a thousand trains derail in the U.S. every year. Far fewer derailments occur on European railways, but accidents still occur regularly. Electronic systems can play a role in improving safety for freight and passengers.

Many railroad functions rely on electrical connections. Wires go in and out of the signal houses at crossings to power and control the crossing gates, the bells, and the flashing lights. Track signal cabling runs underground, connecting the rails and trackside equipment to the control and monitoring equipment inside cabinets and bungalows. Hotbox detectors and tag readers installed along the tracks often use wheel sensors to determine when a train approaches and turn on the device to monitor the train as it passes. These systems keep track of cargo; identify location, speed, and direction while monitoring the health of passing trains to identify potential failures before they create an unsafe condition. Without secure connections, none of these systems can reliably perform their intended functions, so it is easy to understand their importance.

ITT VEAM CIR connectors from Mouser Electronics use a positive-lock/quick-disconnect bayonet coupling mechanism to provide high shock and vibration resistance without the need for lock wires. VEAM CIR connectors comply with EN 45545-2 NFPA 130 fire and smoke standards, VG95234/MIL-DTL-5015 standards based on diverse plating options, and are RoHS and REACH-compliant.

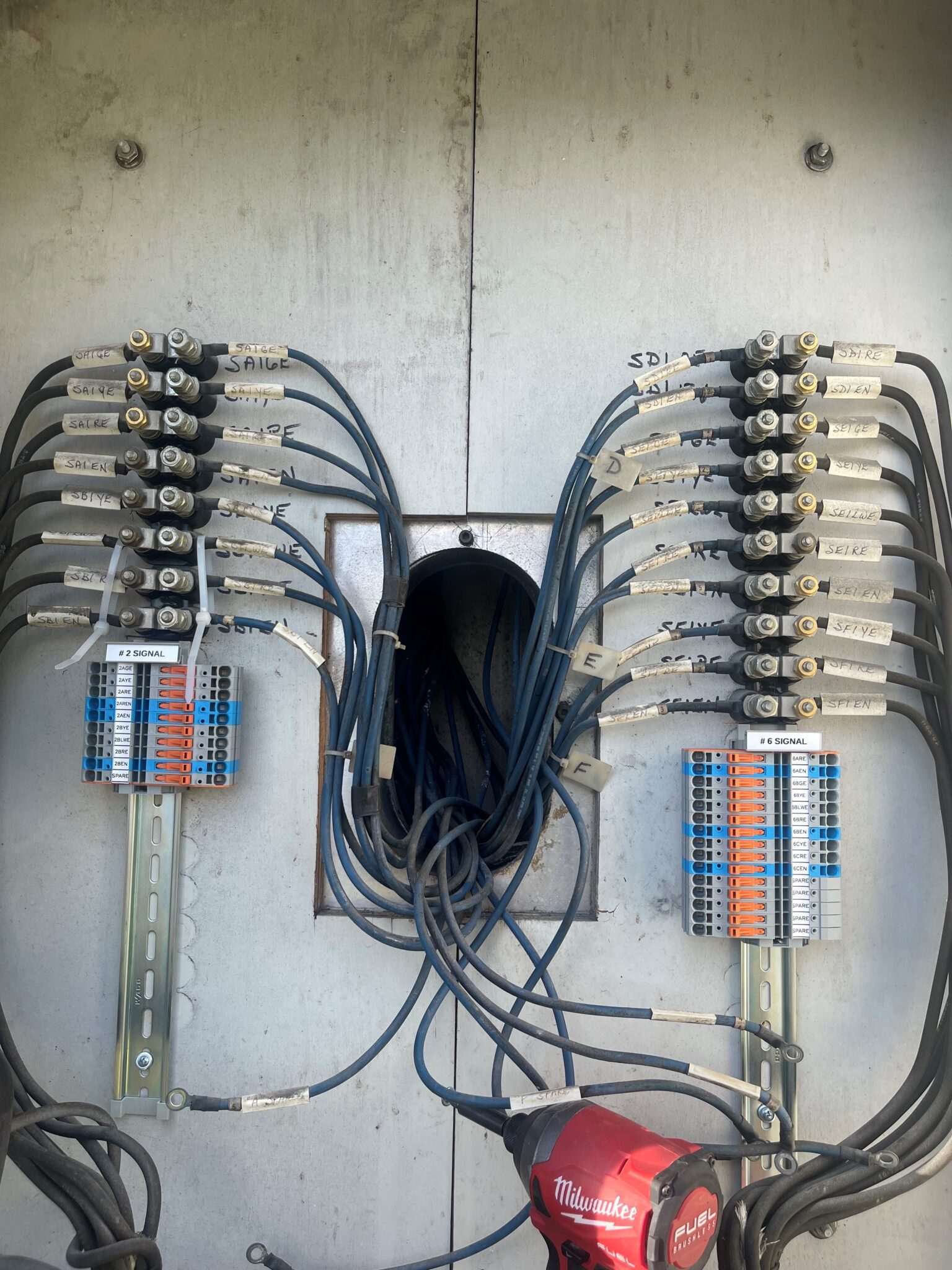

Whether on the trains, on the tracks, or housed in bungalows near the tracks, railway connectors are subjected to significant shocks and vibrations, as well as extreme temperatures. Many railway companies in the U.S. and Canada continue to rely on a system of screws and ring lugs mounted on Bakelite, a resin invented in the early 1900s, to secure the wires. This is the original standard, sometimes called AAR terminals or AAR posts and ring lugs, after the American Association of Railroads. These arrangements can be assembled securely but, when subjected to the shock, vibration, and temperature extremes of the rail environment, they are at risk of coming loose and letting air in between the terminal, the connector, and the crimps. This can cause corrosion and lead to intermittent or failed connections, which can stop a train and potentially result in unsafe scenarios.

Current connector technology simplifies these connections, making them more secure, as well as less time consuming to install, test, and maintain. These connectors are also less expensive and take up less space.

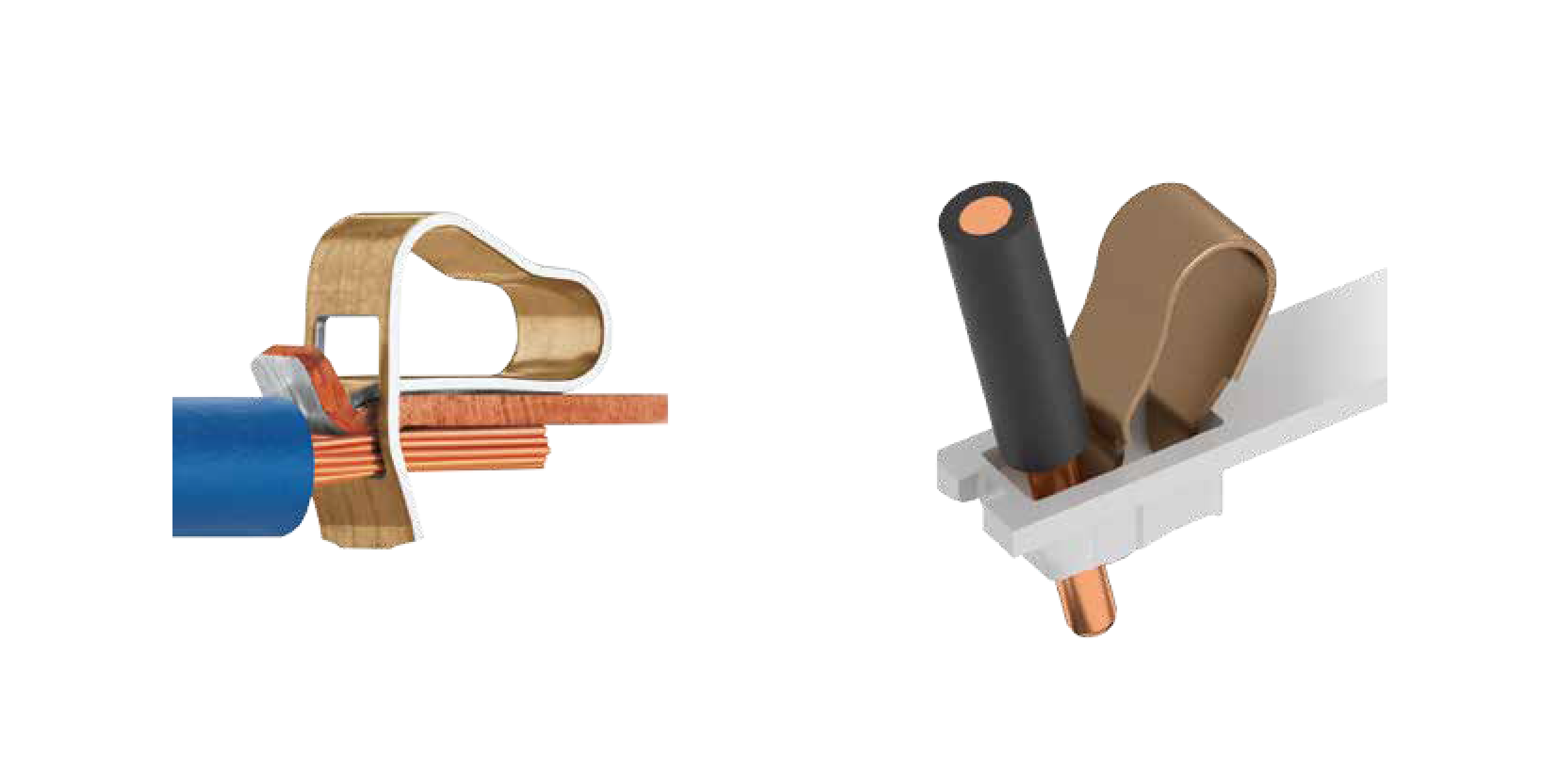

“Basically, every time you attach a wire to any of our products, whether it’s as a terminal block or connector, or even automation equipment and power supplies, those wires go into a Cage Clamp, which is spring pressure technology,” said Brian Ley, industry manager-railway at WAGO Corporation. The cage clamp holds a wide range of wires in the same device, without the need for a crimp tool; just strip the wire and put it in without the need for torquing of screws. The cage clamp is proportional and dynamic, which is important for maintaining the connection despite the shocks and vibrations and the wide swings in temperatures. “You can put in a large wire and it holds it properly and meets all the specs and you can put a very small wire into the same device and it meets all the specs. The spring follows the wire. If the wire is conducting, it heats up and expands. The spring expands with it but maintains that gas-tight connection. When that circuit is off, or the ambient temperature comes down, the spring follows the wire as it contracts,” Ley added.

The WAGO Cage Clamp. The original design (left) holds a stripped wire that is inserted. The push-in (direct insertion) version shown can be used with a ferruled, solid, or substantial stranded wire. To remove the wire, simply open the spring, using either a tool slot, push-button, or lever.

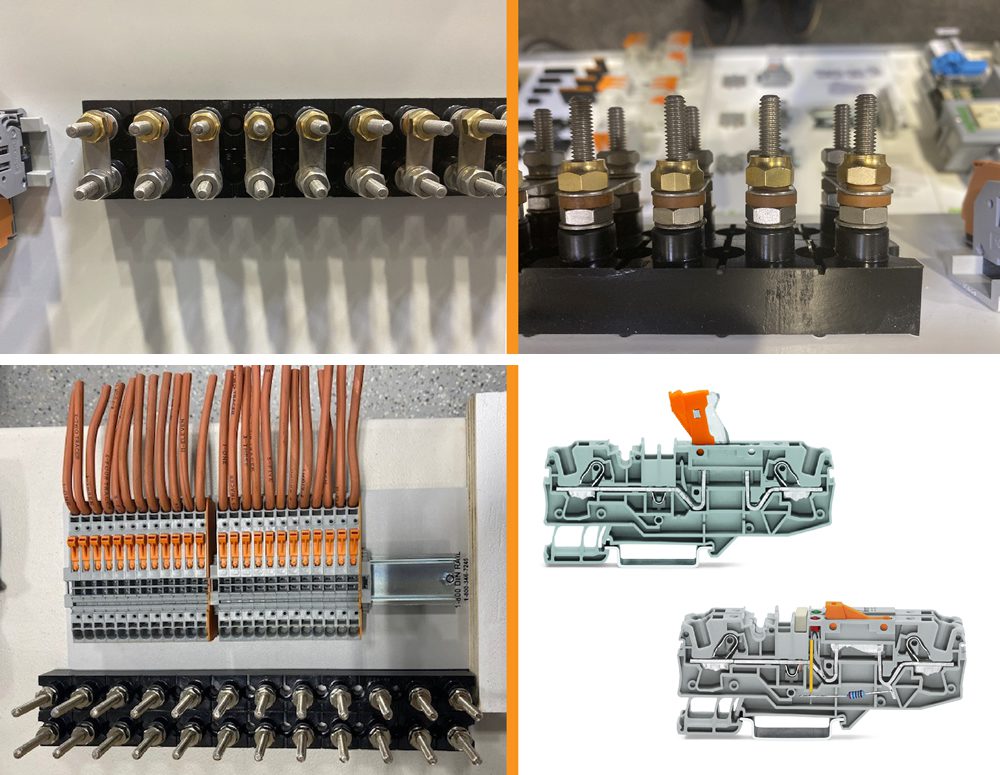

Existing technology (top) that is still widely used in the U.S. and Canada. On the bottom are DIN rail mounted, molded case terminal blocks with spring pressure technology. (Images courtesy of WAGO)

To test the system of wires, nuts, and ring lugs, someone goes through the installation and loosens all the gold nuts to disconnect the wires. The image above shows the gold nuts loosened to different degrees from tight on the left to very loose on the right. Once testing is complete, all the nuts must be tightened with a torque wrench. This takes time and there is no easy way to spot a nut that wasn’t properly tightened. The DIN rail connectors on the bottom have a knife disconnect (shown above in orange) that is either up or down, clearly indicating if it is connected or disconnected.

This image shows a combination of old-school AAR terminals with gold nuts and newer DIN Rail molded case terminal blocks. The orange switches on the newer products make it easy to spot any disconnects. (Image courtesy of WAGO)

The newer technology offers many advantages.

- Saves space (more than 50%)

- Saves wiring time (more than 50% faster)

- Touch safety

- Gas tight connection

- Levers replace gold nuts (less expensive, more secure)

- No crimp tools or torque wrenches needed

- No ring lugs or bent eyelets

- Clear and permanent marking

- Vastly improves reliability

The DIN rail solutions are modular. Any terminal block can be replaced individually, if necessary. With the old system, if a bolted connection is stripped out, the whole assembly has to be replaced and rewired.

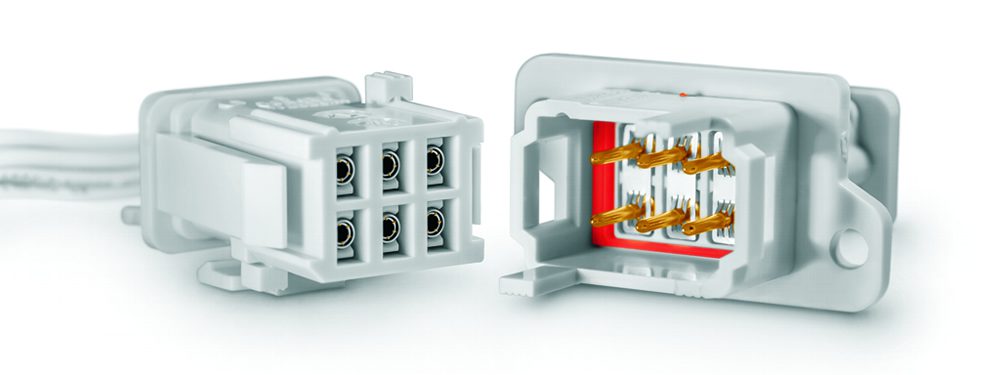

TE HDC series from Avnet complies with the EN45545 European standard on flame retardancy for materials and products in railway rolling stock. HDC inserts meet R22 and R23 requirements set on level HL3. The modular inserts enable signal, data, and power to be transmitted via one single connector with a high level of flexibility when configuring railway connector systems.

Railway standards for electronic equipment cover a variety of issues in addition to shock, vibration, and temperature. Connectors and cable assemblies must be compliant with requirements for passenger and cargo trains. Specifications established by AREMA (American Railway Engineering and Maintenance-of-Way Association), APTA (American Public Transportation Association), EN (European Norm), and others address electromagnetic compatibility (EMC), power supply voltage, smoke and flammability, smoke toxicity, and more.

Quick-mating REP panel and cable connectors from Smiths Interconnect are a highly cost-effective interconnect solution for rail applications. The series is qualified to French and European rail standards and ensures IP66/IP67 protection, high resistance to shock & vibration and fire, smoke, and toxicity compliance to EN 45545.

As rail operators and train designers continue to incorporate new technologies into our transportation networks, connector suppliers are meeting the challenge with solutions that are safe and secure; easy to install, test and maintain; and save space, time, and money.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for WAGO, Avnet, TE Connectivity, Smiths Interconnect, Mouser Electronics, and ITT Cannon.

Like this article? Check out our other Harsh Environment and Terminal Blocks, our Transportation Market Page, and our 2022 and 2023 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024