Secure Connectors Rev Up Automotive Safety

As automotive manufacturing advances, high-speed, press-fit, and other connector technologies evolve to meet current industry demands.

Today’s cars are essentially high-end computers on wheels. A decade ago, vehicle electronics centered on basics like power windows, anti-lock braking systems (ABS), and satellite radio. Today’s cars contain a full suite of safety, comfort, and convenience features such as lane detection, blind spot alerts, 360° cameras, heated steering wheels, and parking assist. These technologies rely on sophisticated interconnects that gather and process data, much of it coming from optical cameras, sensors, lidar, and radar. High-speed, secure connectors manage the data demands and protect signal integrity, while press-fit technology provides security and robustness.

Ensuring a high quality, reliable signal

“Automotive has always been a high safety environment, but with new products such as ADAS [advanced driver assistance systems], high speed is now at the forefront in the automotive game,” said Joshua Jacobi, chief sales officer at ept connectors. “The car is now a cell tower and high-performance computing machine. Signal integrity and security are a must. Extremely precise products are required to meet the speed and special material requirements to ensure that the signal is protected.”

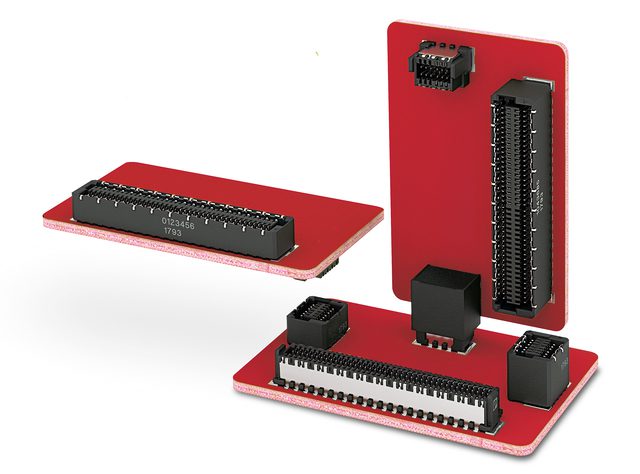

Cameras and sensors around the vehicle constantly take in data. This data is processed in real- time by in-vehicle software, which instructs the vehicle to activate automated functions or conveys information to the driver, such as an alert when another vehicle is in the driver’s blind spot. The system may also display graphics, like a map for GPS or a live image of the area around the car. “This requires a graphics card, like a gaming computer,” Jacobi said. “Automotive manufacturers need high-speed secure connectors to make sure that their cameras, sensors, and computers are working efficiently and reliably. The Zero8 PCB connector series from ept is an example of a robust connector that is secure enough for the high-vibration automotive environment.”

ept’s Zero8 0.8 mm SMT PCB connector with ScaleX technology ensures reliable mechanical and electrical connects, and data transfer rates greater than 16 Gb/s. With optional shielding, it achieves excellent EMC characteristics.

While high-speed secure connectors are ideal for managing the flow of data, press-fit connectors are better suited for getting the data from the control module to the main computer or to a gateway security platform, Jacobi explained. “Extreme robustness is required especially on safety-related aspects, which is where press-fit is a requirement, as the field failure analysis is the safest of all connection types.”

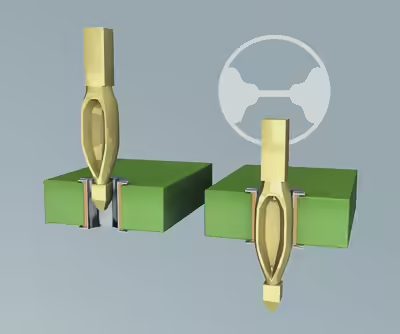

Press-fit technology has been an automotive staple for decades and is specified by USCAR (United States Council for Automotive Research). In addition to the functions already mentioned, press-ft is used in the engine controller for fuel injection and ignition, as well as control of turbochargers, monitoring exhaust gas values, and the monitoring of start/stop systems. The electrical-mechanical connections are made with controlled force, as the pins have a slightly larger diameter than the holes in the PCB. As pressure is applied, the holes deform slightly and the flexible interior of the connector’s terminals absorb the force. This process of cold welding creates a stable atomic lattice that allows electricity to pass through. It is similar to thermal welding, but without introducing heat that could damage the PCB and nearby electronics. As a solder-free option, it eliminates soldering defects and flux residues.

Press-fit technology provides an electrical, mechanical, gas-tight, corrosion-proof, and low-resistance connection with high retention forces.

USCAR Compliance

To meet USCAR specifications, automotive manufacturers must demonstrate 100% compliance for all qualifications, including materials, dimensions, and testing requirements. “This is largely measured by optical equipment or even CT [computerized tomography] scans to ensure that if a customer needs to replace, repair, or initial install the connector, it fits into the system seamlessly and without issue. Even if a robot is doing the installation, it must fit perfectly the first time, as machines don’t wiggle or align by feel when placing the part,” Jacobi said.

Because of these extremely strict requirements, parts cannot become obsolete for a minimum of 15 years after the program life for a given car model, which is typically about seven years. A priority for connector suppliers, therefore, is keeping their products on hand, in some cases indefinitely. “One of the best approaches is being vertically integrated — making your own components and machines to ensure they will not be obsoleted and you can support the manufacturers for many years to come,” Jacobi said.

Another consideration is the supply chain, he says. “This is likely the single largest issue we have faced, especially since COVID-19. To manage it, you must have production around the world and supply chain partners or be vertically integrated. Ept is vertically integrated. We do the molding, stamping, assembly, plating, and testing in our locations in North America, Europe, and Asia to ensure all customers are supported around the globe with local and direct support,” he added.

USCAR connectors include a mix of new and legacy products, such as the venerable TE/AMP line available from Mouser Electronics. Mouser stocks TE’s FAKRA automotive connector system, which is based on FAKRA RF and USCAR standards requirements and includes RF cable assemblies, terminals, and housings.

Many regulations and specifications go into the design and manufacture of an automobile. Ensuring the connectors used are robust and reliable enough for the life of the vehicle is critical.

Visit the Preferred Supplier page for ept to learn more about the company and its products.

Like this article? Check out our other articles on Manufacturing and PCB, our Automotive Market Page, and our 2023 and 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024