Plastic and Metal Connectors for Harsh-Environment Applications: A Pros and Cons Selection Guide

Metal connectors can endure the very roughest conditions. Plastic connectors offer exceptional resistance against moisture. Each material has advantages and disadvantages that make it important to select the right one for your harsh environment application.

Anyone in search of a rugged connector for a harsh-environment application will be confronted with a wide range of choices. Choosing the ideal connector for a particular application requires a careful assessment of the application and the environmental conditions the connector may have to face during its life cycle. For example, in high-traffic industrial environments, connectors might be stepped on, thrown on the floor, or pulled roughly. In transportation and outdoor applications, connectors could be exposed to freezing conditions, rain, mud, or direct sunlight. In medical, food production, and industrial environments, connectors are at risk of being exposed to corrosive chemicals and washed down with high-pressure sprays. Marine and coastal environments are likely to subject connectors to salt spray, humidity, and even submersion. Ensuring uninterrupted connectivity in harsh environments like these is quite a challenge, and requires durable, environmentally sealed connectors capable of withstanding even the most severe conditions. Solutions can include plastic connectors and metal connectors, as both are widely available in harsh-environment designs, but making the right choice can be challenging due to that wide range of options. To ensure optimal selections, it can be helpful to review the various advantages and disadvantages of both plastic and metal connectors as they pertain to different kinds of applications.

Advantages of Plastic Connectors

Lightweight, versatile, and cost-effective plastic couplings are less prone to the risk of moisture accumulating within the connector and more resistant to attack by saltwater. They are also more UV-stable, which makes them ideal solutions for long-term use in outdoor applications.

Plastic connectors also offer:

- More options for customized designs

- Better ergonomics

- Greater flexibility

- Lower per-connector costs

- Quick connections for easy service and maintenance

- A wider range of color-coding options for easy identification

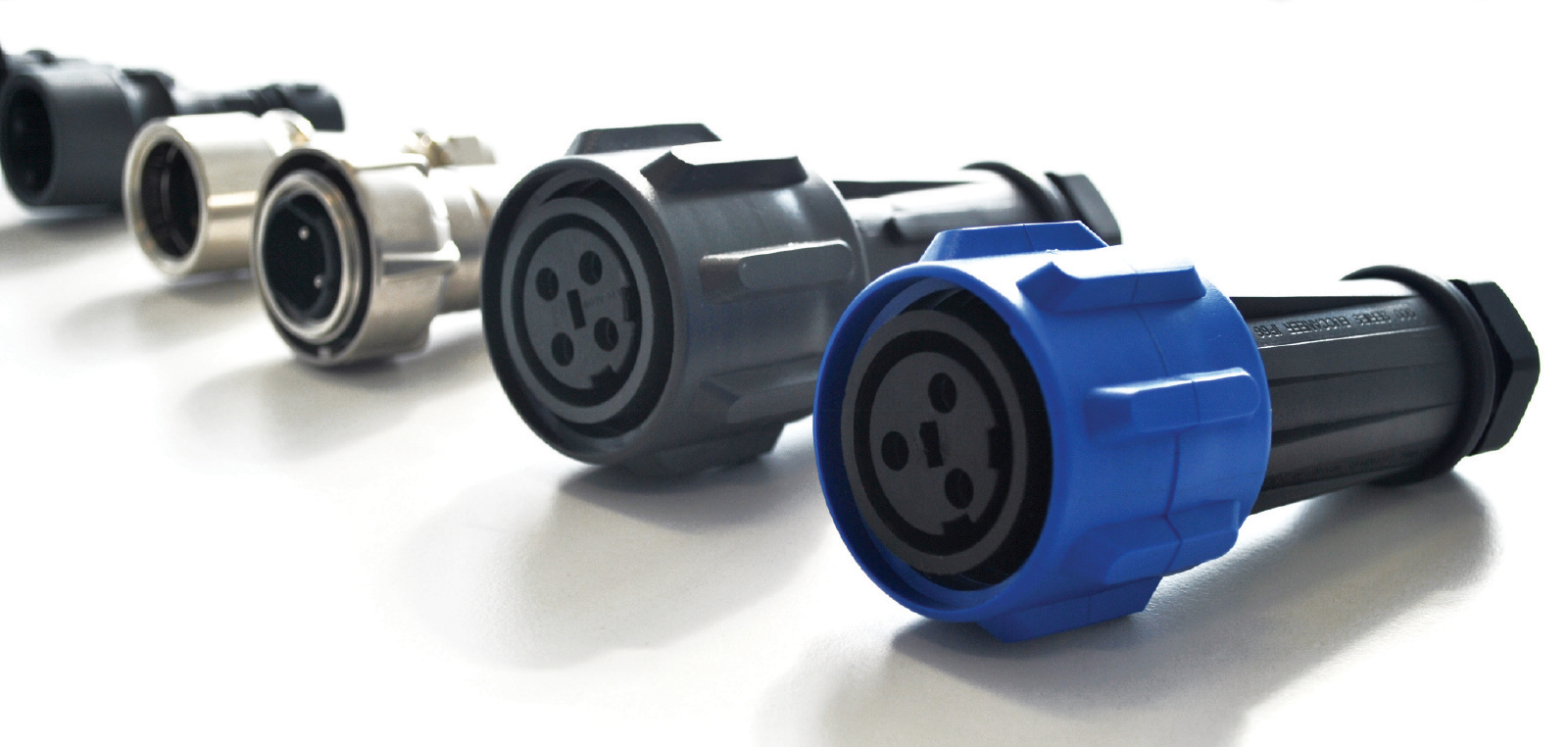

Bulgin’s 400 Series Buccaneer miniature power connectors have a rugged, lightweight construction with reliable sealing, offer numerous configurations for enhanced design flexibility, provide highly reliable power or signal connections, and are ideal for use in space-constrained medical, industrial, infrastructure, transportation, and automotive applications.

Disadvantages of Plastic Connectors

However, not all types of plastic connectors are suitable for use in transportation, industrial, medical, laboratory, or other harsh-environment applications. Plastic connectors may break faster than metal connectors, as long-term exposure to heat or direct sunlight can decondition certain types of plastic, causing cracks and deterioration.

Advantages of Metal Connectors

Metal connectors are generally more suitable for applications that require extreme environmental resistance and electromagnetic compatibility, as they can complete a Faraday cage to block electromagnetic fields by providing a continuation of the cable screen from the cable through to the mating connector.

Metal connectors also offer:

- Extreme durability

- Robust resilience to high temperatures

- Compatibility with food-grade and other sterile environments that require stainless steel

- Improved resistance to chemical corrosion

Bulgin’s wide range of M12 connectors provide efficient, reliable, and cost-effective connections ideal for sensor and fieldbus systems in process control, industrial machinery, and factory automation applications. They have a small footprint, a high degree of mechanical and electrical stability, and an extremely low failure rate, are sealed to IP67, and significantly reduce installation time and maintenance downtime with flexible plug-and-play connectivity.

Disadvantages of Metal

However, metal connectors are heavier than plastic connectors, have a higher per-connector cost, and may rust in marine environments or if exposed to moisture for long periods of time.

Dual-Material Solutions

For maximum application flexibility, users can also mate metal connectors with plastic connectors. For instance, customers that require effective protection from electromagnetic interference (EMI) can choose to combine a metal connector with the corresponding plastic mating connector to reduce the interconnect cost as much as possible while still meeting application requirements for enhanced EMI protection. Similarly, a plastic connector could provide an ideal application solution with regard to cost, flexibility, and ease of maintenance, but require the additional strength and robustness of a metal connector on the cable mounting half of the interface to ensure it is not damaged in use.

Bulgin’s Buccaneer® range of circular, dust- and waterproof connectors for power and data are suitable for use in external or internal environments and are ideal for applications in which ease of connection, space, and appearance are also important considerations.

Continuing Developments

Despite many of the traditional limitations for plastic, new types of plastic compounds are now increasingly able to meet demanding industry requirements in many harsh-environment applications. Plastic connectors are even steadily replacing metal in some of the most challenging and specialized harsh-environment applications, including laboratories and a wide spectrum of industrial environments.

Selecting a Solution

An ever-expanding range of both plastic and metal power, data, and signal connectors designed to provide peak performance in harsh environments are widely available through distribution. Additionally, leading connector suppliers like Bulgin can offer expert advice about how to choose the best product for your application or, if an off-the-shelf solution isn’t readily available, provide custom-engineered solutions.