Onboard Technologies Chart Plain Sailing for Autonomous Shipping

Onboard technologies, including networks of instruments and high-tech navigation equipment, have prepared boats and ships for the next step: autonomous operation.

A proven history of semi-autonomous operation using networked instruments means that the maritime industry is well prepared for the next autonomous phase. Companies like Garmin supply chart plotters and auto-pilots for commercial vessels, cruisers, sailboats, and powerboats. The autopilot system is connected to the vessel’s hydraulic or mechanical steering system and reacts to conditions. It can hold a course that has been set, even when the boat is pitching in rough waters.

Onboard Communication Systems

Smaller yachts and boats rely on navigation instruments connected to wind, depth, and speed transducers. They may also be connected to a sonar instrument. Data is transmitted to multiple, dedicated displays via an NMEA0183 network, a combined electrical and data specification for communication between marine electronics and other instruments, such as such as an echo sounder, sonars, anemometer, gyrocompass, autopilot, and GPS receivers. The NMEA0183 interface standard has been defined and is controlled by the National Marine Electronics Association. Another data protocol, Raymarine’s proprietary SeaTalk network, also operates on a serial data protocol.

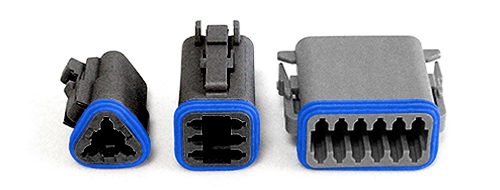

Transducers, GPS sensors, the course computer and autopilot, and their respective keypads, as well as the vessel’s power supply, are all connected to the network using small diameter cable connectors to make installation easier. In the Raymarine system, cable lengths vary but the company supplies all cable with overmolded plugs, so there is no need to cut or splice cables. For ease of installation and identification, Raymarine supplies color-coded cables to minimize the risk of misconnection, for example, or distinguish power cables from spur cables. The connectors used in these systems are from Bulgin’s Buccaneer Standard Series and are designed for quick connection, with a push-fit, twist lock operation. They are also waterproof.

Bulgin’s Buccaneer Standard Series of IP-rated circular connectors are ideal for marine applications. These dust-proof and waterproof connectors are IP68 and IP69 sealed.

Mating and Unmating

In larger vessels, onboard instruments and equipment are typically permanently installed in the bridge. In others, users may want to disconnect instruments to bring ashore, or for repair. A sealed outlet for the electrical cable allows for safe disconnection of onboard technologies. The interconnects used are typically two- or three-pole connectors, with a sealing grommet for the cable. Connectors supplied with a rubber gasket ensure a good seal, although Richard Roberts, managing director of Boat Fittings, a specialist supplier of hardware, instruments, fittings, and tools, advised using an additional silicone sealant to secure a good seal. Another feature is a locking ring to push the connector pins into place and make sure the connection will not be dislodged. A design with brass casing and chrome plating is good for harsh marine environments, added Roberts.

Many connector companies provide waterproof connectors but not all are specified for marine use. Amphenol LTW, however, has a range of plastic or metal connectors specifically for marine applications. The DeepTronica series consists of the Xiento-2M and Abyss circular connectors. They can be mated (and unmated) underwater as well as dry-mated and are available with plastic or metal sleeves. The range is designed to minimize size and weight onboard watercraft. For example, they can be configured with power or signal contacts, or a combination of the two in a hybrid version. They are also available with a bulkhead design for panel mounting.

Amphenol LTW’s Xiento-2M series operates at up to 200 m underwater, while the Abyss is suitable for 6,000 m. They are available from Amphenol LTW as well as distributors such as Arrow, Digi-Key, and RS Components.

Underwater Operation

For rugged underwater connector technology, TE Connectivity has developed the Seacon range. This portfolio of rugged underwater electrical and fiber optic connectors includes dry-mate and wet-mate electrical circular connectors as well as hybrid and optical connectors and underwater switches. All are designed with small, lightweight but rugged packaging to facilitate installation in the limited available area onboard a vessel.

TE Connectivity’s Seacon range includes the Globe-Con series, designed with a bulkhead connector receptacle and a glass reinforced epoxy (GRE) insert and a metal shell. It has up to 28 gold-plated contacts and a fluroelastomer O-ring. The cable connector plug of the design is GRE and molded in neoprene to standard or custom cable lengths. A spring ring is included to increase reliability during high vibration. Its current rating is up to 1.5A and Ethernet versions are available, making it suitable for use with small sensors as well as communications systems.

Autonomous Vessels

The use of sensors is significant, because sensors around a vessel hold the key to the next stage in maritime technology. Autonomous ships, like cars, are classified according to degrees of independence and human interaction. Industry watchers pointed out that if large shipping vessels could navigate oceans to deliver goods without crews, the cost of shipping would decrease.

Allied Market Research commented that autonomous ships could be “the next disruptive force in international transportation” and predicted a CAGR of 4.4% from 2020 to 2030, which would value the global autonomous ship market at just under $135 billion by 2030.

Shipping has a lower carbon footprint than air transport. Having onboard technologies in control of navigation and collision avoidance could make shipping safer in the future. The European Maritime Safety Agency (EMSA) reported that more than 1,500 general cargo ships were involved in accidents in 2017, and that for all maritime casualties, half were related to navigation error, such as going aground or collisions.

Sensors are vital for all levels of autonomous vessels. The International Maritime Organization defines four levels of automation. 1: A ship with automated process and decision support from crew. 2: A remotely controlled ship with seafarers on board and available to take control. 3: A remotely controlled ship without seafarers and 4: A fully autonomous ship with an operating system able to make decisions by itself.

Onboard technologies such as lidar, radar, and IR sensors will feed data to the positioning system. This data will also be used when berthing and mooring without assistance from the crew. Other communications systems will relay data from onboard systems, such as main engines, propellers, and machinery, to a central control and monitoring system as well as GPS and weather monitors.

Research Projects

There have already been some interesting research and collaboration projects around this goal. Rolls-Royce and Intel announced a partnership to design intelligent shipping systems with artificial intelligence (AI) capabilities and edge computing for navigation, obstacle detection, and communications.

Finferries demonstrated an autonomous trip with VIPs onboard the double-ended car ferry.

In 2018, Rolls-Royce established an R&D center in Turku, Finland, and is working with the country’s ferry operator, Finferries to develop an autonomous ferry. The 53.8m car ferry, Falco, made an autonomous voyage in the archipelago south of the Turku.

A semi-autonomous canal boat, using Shipping Technology’ and Xonmia’ data system.

In the Netherlands, semi-autonomous 10-meter-long canal boats are sailing in the shipping lanes using motor management, radar, and GPS data which is processed onboard. The system was developed by maritime automation specialist Shipping Technology and AI consultancy Xomnia to not only navigate the straits but to send real-time updates and historical data to the owner. These vessels are beta-testing the onboard Black Box Pro computer and software and will collect more data as the number of voyages increases. The expectation is that the gathered data, combined with the crew’s behaviour and reaction to certain situations, will be the basis for algorithms to determine the best navigation routes, streamline loading and unloading operations, and contribute to predictive maintenance systems.

To learn more about the companies mentioned in the article, visit the Preferred Suppliers pages for Amphenol LTW, Bulgin Components, and TE Connectivity.

Like this article? Check out our other ruggedized, and high-reliability articles, our Transportation Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Matter: A Show of Unity for Connectivity - September 5, 2023

- Brexit Update: UK Connector Industry - March 28, 2023

- Sensors Make it Plain Sailing for a Smart Ferry - February 21, 2023