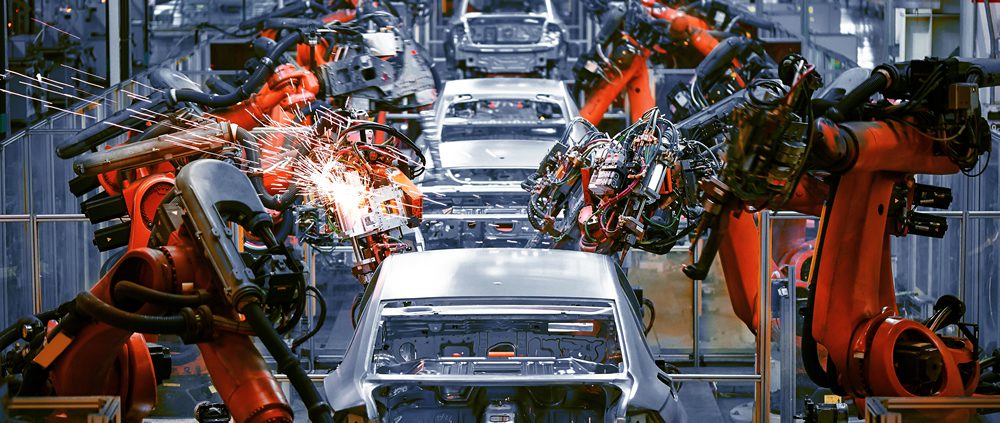

New SPE Standard Revolutionizes Automotive Manufacturing

Single-pair Ethernet technology has been integrated into recent models of automobiles, replacing controller area network (CAN) and other bus systems, with an eye towards a future in which controls, communication, and safety functions will run on Ethernet. Meanwhile, these advantages can also serve industrial automation and automotive manufacturing.

Automotive manufacturers have long had access to the high-speed communication capabilities of industrial Ethernet. The technology has proven its reliability, enables flexible automation, requires less investment, and helps reduce operational costs. However, there has been a gap at the field device level. Machine sensors and actuators have been held back from communicating with the rest of the network by analog and fieldbus technologies that do not speak the same “language” as high-speed Ethernet.

Fortunately, the new industrial single-pair Ethernet (SPE) standard changes all that, enabling virtually barrier-free connection from the cloud to the field devices connected at the edge. This nearly seamless connection will allow industrial communication to become more transparent and helps unlock greater artificial intelligence (AI) and machine learning capabilities for automotive manufacturers.

Defining a common industrial SPE standard

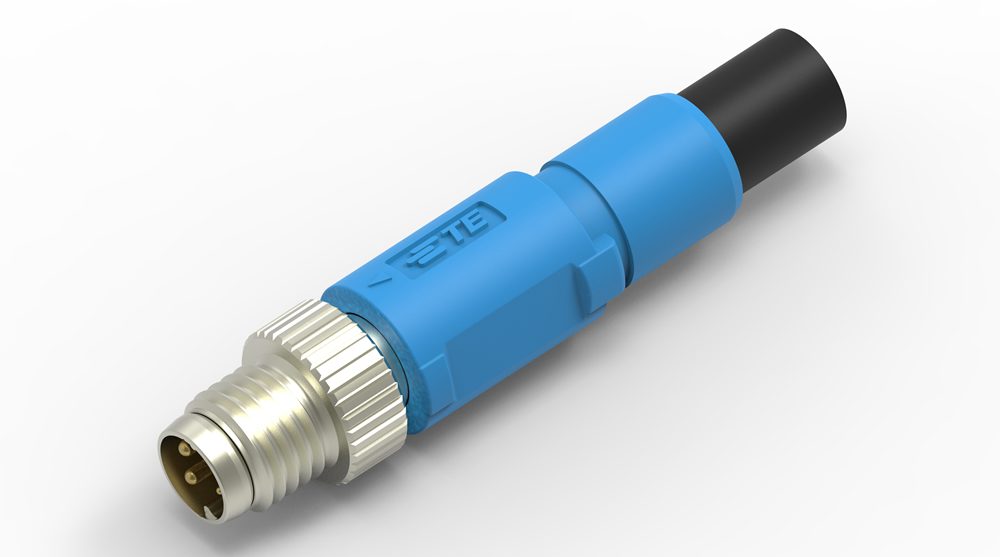

Established in September 2021, the industrial standard for SPE calls for an IEC 63171-7 cable with a M12 connector. The IEC 63171-7 (or “-7,” for short) provides an interface for hybrid SPE and power transmission in one cable, with high-speed data transmission up to 1 Gb/s/600 MHz and power up to 11 kW/16 A. This allows engineers to optimize machine-to-machine communication in their applications without loss of data, to decentralize computing power, and get data to the edge of the network in a more streamlined, transparent way.

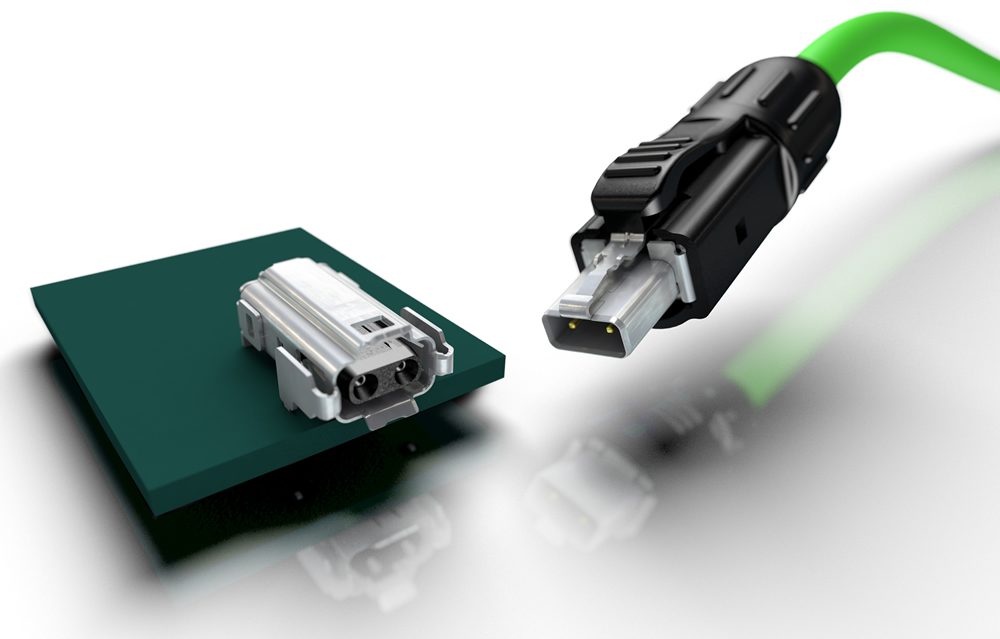

TE Connectivity’s SPE T1 industrial connectors (IP20). Instead of transmitting Ethernet over two pairs (for Fast Ethernet (100Mb/s) or four pairs (for Gigabit Ethernet), Single-pair Ethernet (SPE) specifies Ethernet transmission over only one pair of copper wires.

Instead of transmitting Ethernet over two pairs (for Fast Ethernet (100Mb/s) or four pairs (for Gigabit Ethernet), Single-pair Ethernet (SPE) specifies Ethernet transmission over only one pair of copper wires.

TE Connectivity’s single-pair Ethernet (SPE) solutions include the M8 hybrid board receptacle (IP67) and SPE M8 hybrid cordset (IP67). The M8 Hybrid solution also provides power transmission over a separate wire pair. Data transmission is possible up to 1 Gb/s, and power supply up to 400W. At 10 Mb/s speed transmission distances up to 1,000 meters are possible.

Adopting the -7 as the industrial SPE standard has several additional advantages for automotive manufacturers:

- It melds seamlessly with existing Ethernet infrastructure.

- It provides simple plug-and-play connectivity capabilities.

- Like today’s fieldbus and analog solutions, it uses a single cable and connector combo that is built to withstand harsh environments and is resistant to vibration, shock, welding sparks, chemicals, and high temperatures that are commonly found in automotive manufacturing applications.

- It uses separate pins for data and power contacts, increasing the power options.

- It provides the reliability, durability, and security that are required in automotive manufacturing settings.

- Its one-cable/one-connector design reduces overall cost and allows it to fit smoothly into compact spaces — important for the ongoing trend toward miniaturization.

Making field-level insights more accessible

Aligning on the -7 standard is a key step in making the bold future of Industry 4.0 possible for more automotive manufacturers. This slim, lightweight, yet powerful connectivity solution enables the industry to digitize at the field level and is a critical part of the industrial internet of things (IIoT) infrastructure. The acceptance of this universal SPE standard will help unlock technological advancements for the industrial market and help more automotive manufacturers optimize production.

Creating a universal standard also streamlines manufacturers’ connectivity choices, allowing automotive OEMs and automation companies to embrace the new technology with confidence so they can install industrial SPE in their field devices (sensors, etc.). Aligning on the -7 standard interface also improves planning security. And it enables automotive manufacturers to gain efficiencies in real-time communication and transparency from the cloud to the field level, thanks to the Ethernet-based hybrid power/data solution. These two areas are key motivators for manufacturers to make the transition to SPE.

Getting ready for the next step in smart automotive manufacturing

Because the M12 connector is already in wide use throughout the industrial market, the -7 standard will be easier for automotive manufacturers to adopt. And it also grants engineers the flexibility needed to design the network that works for their specific manufacturing needs. Since the -7 combines power and data in one cable, engineers can be agile in how they configure software and data to create a barrier-free communication ecosystem from the sensor to the cloud, enabling seamless communication from machine-to-machine and machine-to-human.

The hybrid configuration of the -7 standard also provides increased flexibility to distribute power across networks versus the point-to-point connection that power-over-data-line Ethernet requires. That means it is possible to distribute higher currents to several cascaded power devices.

Bringing greater innovations to manufacturing

Adoption of a hybrid single-pair Ethernet standard moves the automotive manufacturing industry closer to making Industry 4.0 a reality, finally bringing Ethernet capabilities to the edge of the network.

See TE Connectivity’s portfolio of SPE products and services that support advanced manufacturing and Industry 4.0 goals.

Like this article? Check out our other articles on manufacturing and Ethernet connectors, our Automotive Market Page, and our 2023 and 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- New SPE Standard Revolutionizes Automotive Manufacturing - March 7, 2023