Modern Connector Density Eased by Retro Manufacturing Process

Solid machined contact manufacturing, which has been in use for more than 70 years, is now being rediscovered for its power density advantages.

By Natesh Kannan Gopalakrishnan, Product Manager, Positronic

Sometimes, the solution to a new problem is found in time-tested methods, hidden in plain sight. We’re seeing that today in the supply of electrical power.

There is a growing need for more power to be sent through increasingly smaller electrical connectors, as next-generation microprocessors and other components demand more current. The upshot of sending more current through smaller areas is more heat. Previously, the best way to reduce heat was to add space, but that’s no longer an option. In addition, agencies are regulating connector parameters such as creepage and clearance distances to help ensure safety. This further complicates the pursuit of downsizing.

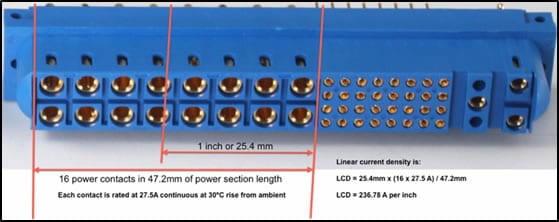

What is required is higher linear current density (LCD), the amount of current that can be fed through a connector within a linear space of 25.4mm (1”) along the connector body.

For the past 40 years, the interconnect world has been highly influenced by stamped-contact technology, which has helped to make mass-produced electronics more affordable. Stamped-contact connector manufacturers have offered what has become known as a blade connector — a type of single-wire connection using a flat conductive blade that is inserted into a blade receptacle — for applications that require high density in small spaces. Though blade connectors offers attractive pricing and some improvements over other stamped-and-formed solutions, they are not dense or small enough to satisfy many current needs.

This is where another time-tested solution — solid machined contact manufacturing — enters the scene. Solid machined contact manufacturing, which has been in use for more than 70 years, is now being rediscovered for its power density advantages.

Solid metal contacts, which are typically made of brass and bronze alloys, are turned or machined on precision lathe equipment that was originally intended for use in the Swiss watch industry, but has long since become a bedrock of precision contact manufacturing operations as well. Since stamped contacts became popular in the 1970s, solid contact connectors became more of a specialty item, used primarily for high-reliability applications, such as those found in the medical, defense, and aerospace industries. But because of their unique capabilities, solid contact connectors have never totally been forgotten.

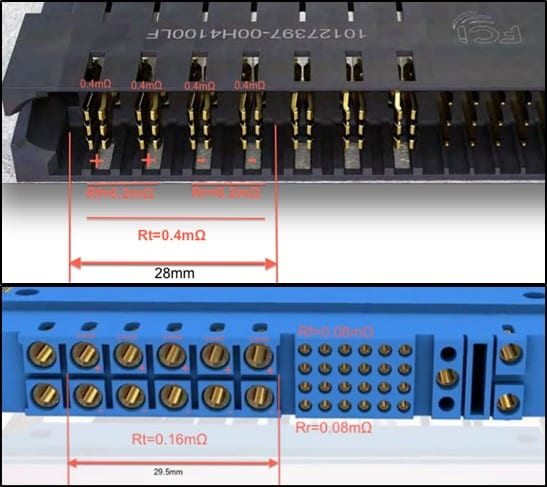

Amphenol ICC’s PwrBlade UTRA Connector System (left) and Positronic’s Scorpion SP Series Connector (right).

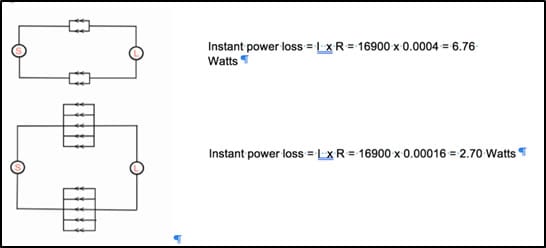

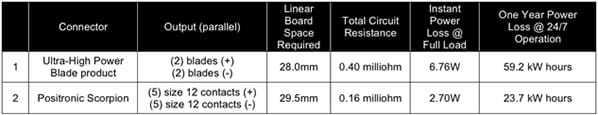

When compared to Amphenol ICC’s PwrBlade ULTRA® Connector System, Positronic’s Scorpion SP Series connector, a machined contact power connector, produces a 0.26% improvement in unit efficiency from 1,560W. In one year of continuous, 24/7 operation, the Scorpion connector saves 35.5kW hours, which translates to more than three dollars of savings. As such, by some point in the third year of operation, the savings in energy costs alone would exceed the entire cost of the Scorpion connector.

The linear current density of the PwrBlade ULTRA (top) compared to the Positronic Scorpion SP Series (bottom).

Solid contact connectors can also enable other cost savings. For instance, when used with advanced mating area designs, they can offer up to two times more power density than a blade connector.

Linear current density details for Positronic’s Scorpion SP Series connectors.

It should be no surprise that the time-tested quality of machined contacts, which have long been used in demanding environments that require certainty of quality, are now providing a viable solution for the electronic industry’s overwhelming demand for smaller, faster, and cooler circuits.