I Need a Wire Harness Assembly

I Need a Wire Harness Assembly

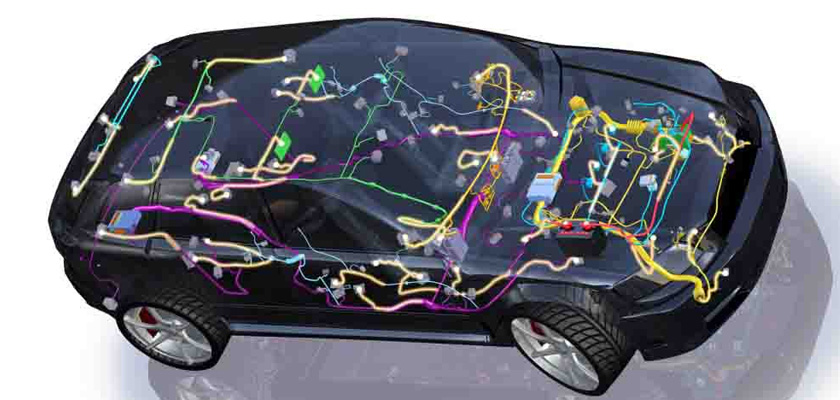

Sometimes the last thing considered in a complex system is the wiring harness. However, as with many sub-assemblies that make up a system, wiring harnesses have many variables that may affect the quote and the quoting process if these variables are not clearly defined early in the quote process. Following is the information typically required to complete an accurate and timely quote.

Basic Information Required for a Wire Harness Assembly:

|

|

If there is no print or no BOM available, the customer will need to provide alternative information, as noted below.

| For a simple prepped wire: |

|

Also, don’t forget there are two ends to the wire. Do you want both ends prepped the same?

| For a wire with a contact crimped on one or both ends: |

|

| For an assembly with one connector: |

|

For all terminations, ensure the insulation thickness of the wire is compatible with the contacts on both ends of the assembly.

Many other options exist even for these “simple” interconnect solutions. For example, if labeling is required, the label size, label type, print copy, and position of the label must be specified. For cable ties, cable tie part number and position on cable should be included. For heat shrink, specify heat shrink manufacturer, part number, color, length of recovered heat shrink, and position of heat shrink. For shielded cable assemblies, the shield termination should be clearly identified.

If cross-references are acceptable to reduce lead time, to replace obsolete components, or to avoid costly tooling charges, make sure this is clearly noted. When possible, specify generic wire call-outs to ensure that your cable assembly supplier can use the wire best suited for their machines. Small wire spools tend to curl wire and jam up machines, increasing scrap and downtime, thus increasing costs.

Some suppliers, like TLC, have a standard quote cover sheet and “boilerplate” quotes for prepped wire, crimped wire, one-connector assembly, and two-connector assemblies to simplify the process for customers.[hr]

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our recent articles by connector market for more applicable, expert-informed connectivity content.