Finding the Right Route for 5G RF Connectors

The arrival of 5G RF networks will bring safe, reliable autonomous vehicles closer to reality. To make this possible, the integrity of RF transmissions must be protected.

5G RF networks promise to transform the driving experience. The ability to handle high-speed data from multiple sensors within both our vehicles and the urban infrastructure around them will enable safer, more efficient travel. With 5G, data can be gathered and transmitted from cameras, radar systems, sonar systems, GPS, and light detection and ranging (LiDAR) systems. Autonomous and connected vehicles will receive and transmit huge volumes of data with the cloud and smart city. In addition, all of this data will have to be processed almost instantaneously to operate a safe, free-flowing traffic system.

5G increases bandwidth by a factor of 10 and reduces latency by a factor of at least 30, compared with 4G networks. The reduction in latency from 4G to 5G is 1.5 milliseconds to 65 nanoseconds, which will significantly increase the refresh rate for information updates, such as real-time traffic conditions. As a result, autonomous vehicles will be able to react quickly to stimuli perceived by radar and sensor systems. Using 4G networks, a car will travel 4.6 feet (1.4 meters) from the moment an obstacle is detected to the execution of a response command (e.g., apply the brakes). Using a 5G RF network, this is reduced to 1.1 inches (28mm).

5G RF Standards

“There is no doubt that 5G will offer lightning-fast coverage of frequencies which were previously used only for military and satellite communications,” said Amos Cheah, senior manager of R&D and product development engineering at TE Connectivity. “The 5G network will play an integral part in speeding up wireless communication.”

5G RF networks will require new standards to support the ultra-fast, low latency applications, Cheah said, and designers will need to address antenna design and the use of multiple-input/multiple-output (MIMO) technologies to increase both data rates and reliability. The reward will be safe, autonomous vehicles equipped with highly capable devices that are capable of high-speed connectivity.

Implementing 5G Infrastructure

Connector companies are already anticipating the implementation of 5G RF networks with a selection of innovative RF products. I-PEX has introduced several 5G RF connectors for mobile applications. Its MHF 7S micro RF coaxial connector has a small footprint (2.0 x 2.0mm) with a low mated height of 1.4mm and is designed to overcome 5G mmWave EMI issues, exhibiting a voltage standing wave ratio (VSWR) of 1.5 at 15GHz operation for reliable antenna transmission. Critical to this EMI performance is an industry-first design that positions the stripline terminated signal pin inside the receptacle grounding ring to reduce EMI. An accompanying micro RF coaxial connector, the MHF 7, which is similarly compact (2.0 x 2.1mm), has a 1.68 VSWR at 45GHz with minimum impedance variation.

I-PEX MHF 7S (left) and MHF 7 (right) micro RF coaxial connectors for 5G RF applications

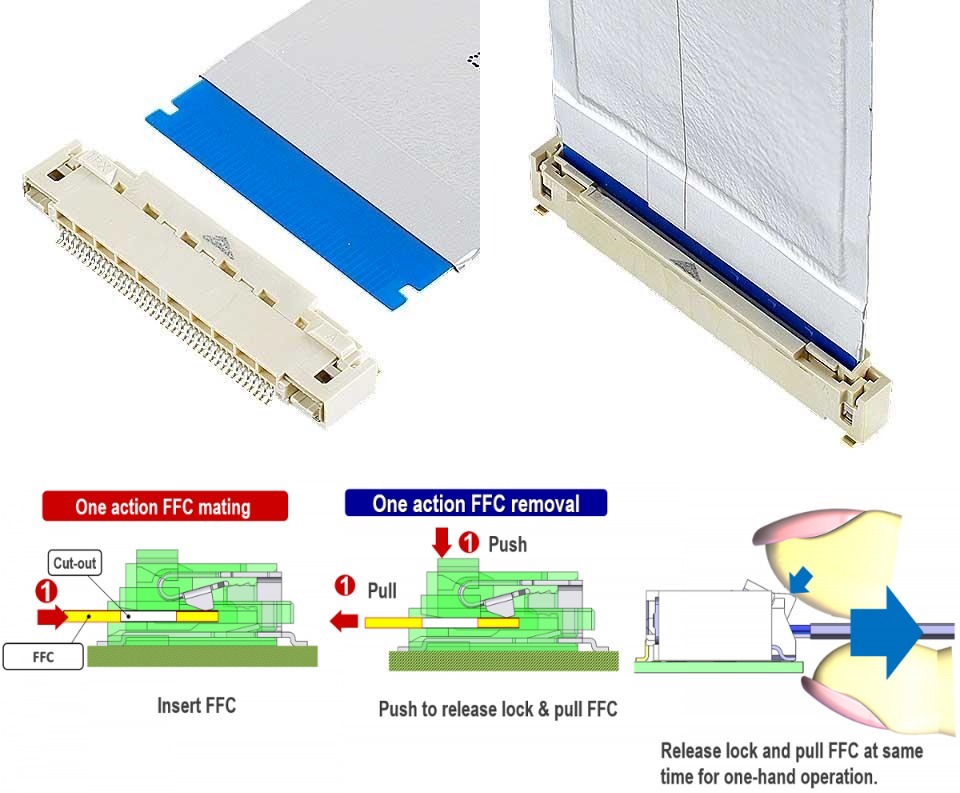

In addition, the new horizontal-mating 5-SE-GHT and vertical-mating 5-SE-GVT RF micro coaxial connectors are part of IPEX’s EVAFLEX 5-SE-G horizontal and vertical mating connector line for 5G RF applications. These connectors have an auto-locking function, operated by a lock-release button, to secure FFC/FPC engagement in the high-shock and -vibration environments encountered in automotive applications. They have also been tested for data transmission in excess of 4Gb/s and operation in high-temperature environments up to 125°C. Both versions have a 0.5mm pitch and are available in pin counts spanning 20 to 60.

The horizontal-mating 5-SE-GHT (top left) and vertical-mating 5-SE-GVT (top right) RF micro coaxial connectors from I-PEX above a mating and unmating diagram for EVAFLEX 5-SE-G series connectors like these.

A one-touch coaxial termination mechanism, developed by AVX Corporation, is used in the company’s 00-6791 Series of RF coaxial IDC connectors. The mechanism is claimed to simplify the connection operation and contributes to the connector’s small form factor, which provides critical save spacing in automotive designs. At its release in 2019, it was believed to be the industry’s first wire-to-board RF coaxial IDC connector for the automotive market. It can also be used in industrial applications.

The two-piece 00-6791 RF IDC connector can be used with different types of coaxial cable and its RF performance exceeds that of cable soldered directly to a PCB. AVX says the connector has a lower component cost and — at 10 x 6.6mm and 3.9mm high — is smaller in size than a traditional two-piece RF connector. This can save valuable real estate on PCBs in space-constrained automotive designs and can also reduce installation time compared to both soldered connections and traditional RF connectors.

The termination process for the 00-6791 RF IDC connector has been pared down to just three stages. Once the outer jacket and braid shield are stripped, the cable can be inserted, with the inner jacket still intact, before the insulator cap is depressed, either manually or automatically, to pierce the coaxial cable jacket and dielectric and make direct contact with the braid shield and conductor at the same time. The connector also has three windows in the insulator cap that allow installers or camera-enabled automated cable positioning verification systems to see the position of the cable and check the termination. If the connector or cable need to be removed for any reason, the caps can be removed to expose the contact tails and allow for reworking or removal.

AVX’s 00-6791 Series RF coaxial IDC connectors have phosphor bronze signal and braid contacts, glass-filled Nylon 46 insulators, lead-free, tin-over-nickel-plated terminations, and a stainless steel support plate. Operating temperatures range from -40°C to +105°C, with heat resistance during reflow extending to 260°C. It operates at 125VAC and frequencies up to 6GHZ and has been tested to 70N of horizontal pull force and 20N of vertical pull force. The connector is compatible with automated SMT pick-and-place machines and automated lead-free reflow soldering, as well as with Bluetooth, GPS, GSM, and WLAN wireless protocols.

Socket Connectors

In some areas of the vehicle, high-speed, high-density socket connectors are used for 5G’s high-frequency, high-data-rate operation. Samtec’s SEARAY SEAF high-density socket connectors are designed to support maximum grounding and flexible routing and can be used for parallel, perpendicular, and coplanar applications. They offer stack heights ranging from 7.0mm to 40mm and operate at up to 56Gb/s. These socket connectors are also equipped with solder on each tail to ease processing and are available with up to 560 single-ended I/Os or 140 differential pairs.

Samtec’s 0.050” (1.27mm) pitch SEARAY SEAF high-speed, high-density, open-pin-field array socket is designed for harsh environments. It is certified to IPC J-STD-001F, class 3 for high-performance, harsh-environment electronic products, offers up to 500 I/Os, and is available in stack heights extending from 7.0mm to 18.5mm.

Samtec’s SEARAY series also includes the right-angle SEAF-RA socket, the SEAF8 0.8mm open-pin-field array, the SEAFP press-fit socket, and the SEAFP-RA right-angle press-fit socket and is dual-sourced by Molex.

Antennas for 5G

TE Connectivity addresses the design of antennas in vehicles that are required for 5G RF wireless communication. The company offers a combination of PCB- and chassis-mount antennas for cellular IoT devices operating in a range of frequency bands, from 600MHz to 6GHz for 5G RF networks.

TE Connectivity offers the 2195729-1 and 2195729-2 external full-band antennas. The SMA male antennas are compatible with 5G, GNSS, and LTE wireless networks and exhibit 50Ω impedance and VSWR of less than 3.1.

TE’s antennas are available with different mounting types, cable lengths, and connector options to meet a variety of specific system architecture requirements and importantly, for ease of integration into end devices, do not require tuning. TE also offers a service for embedding antennas and developing complex, multiple antennas assemblies.

Despite great anticipation for its potential in automotive and other applications, the arrival of 5G RF connectivity has suffered a delay. The COVID-19 pandemic has slowed the rollout of 5G networks, but it has also highlighted the need for its many uses. The pandemic has increased remote working, which, together with other technologies used by people stuck at home, has highlighted the importance of a robust 5G RF infrastructure, says Angela Logothetis, chief technology officer, Amdocs Open Network.

“While we may not see the race to be first or biggest continue throughout this year, it’s only a temporary halt,” she said. “When communications providers can bring their focus back to the rollout later this year or early 2021, there will be pent up consumer demand for devices, connectivity, and innovative services,” she predicts. Within 12 months, she believes there will be a rapid acceleration of 5G RF adoption.

Once established, vehicle manufacturers will be well-positioned to optimize 5G RF networks for ADAS and autonomous vehicles.

Like this article? Check out our other connected vehicles, RF and Coax, and 5G articles, our Automotive Market Pages, and our 2020 and 2019 Article Archives.

- Matter: A Show of Unity for Connectivity - September 5, 2023

- Brexit Update: UK Connector Industry - March 28, 2023

- Sensors Make it Plain Sailing for a Smart Ferry - February 21, 2023