DIN-Rail Mount Terminal Blocks Product Roundup

This week’s Product Roundup highlights DIN-Rail mount terminal blocks from leading suppliers.

DIN-Rail Mount Terminal Blocks

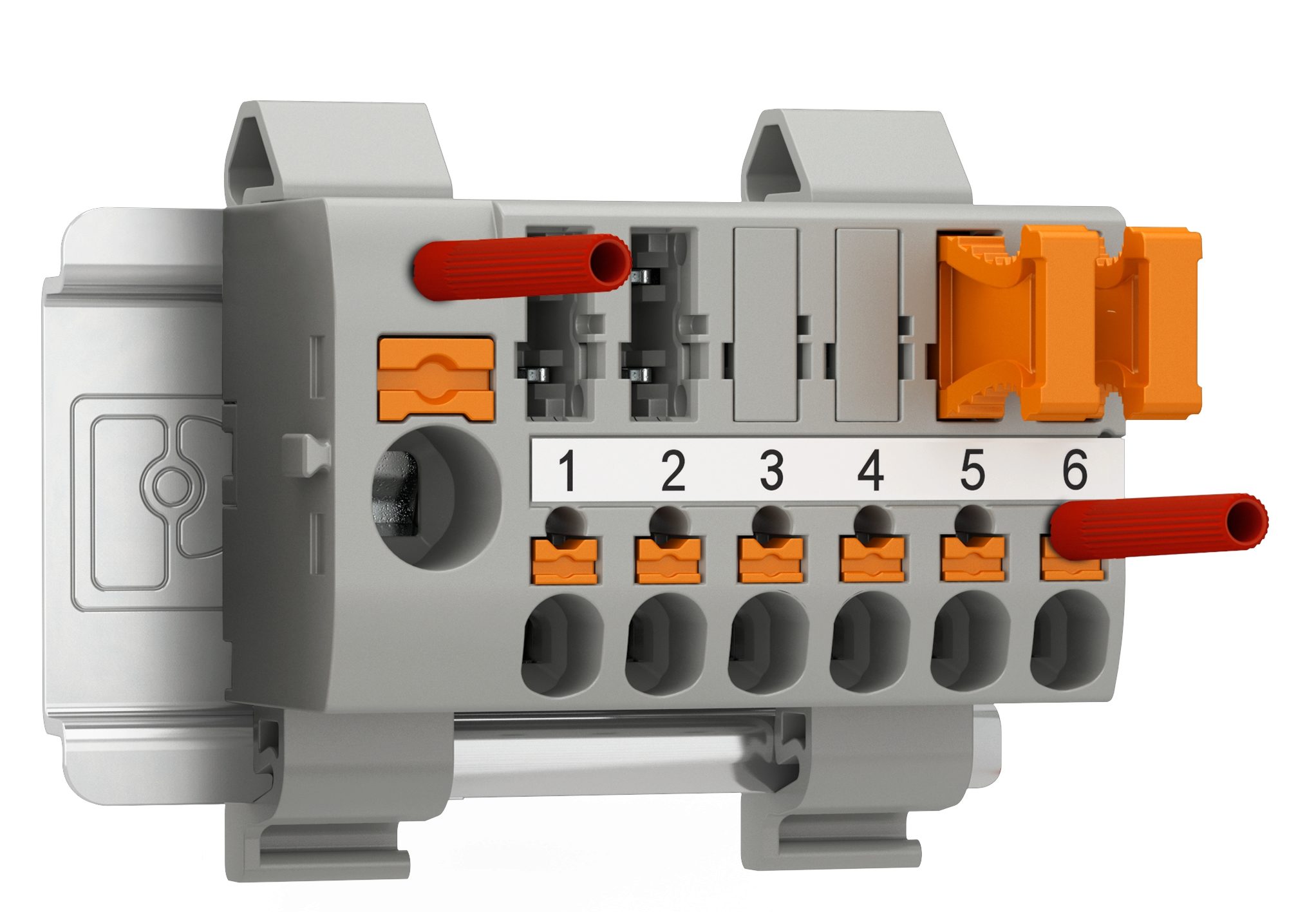

Phoenix Contact has added function blocks to its popular line of PTFIX distribution blocks. The new PTFIX Function features Push-in Technology that can connect, disconnect, and protect terminal blocks. Disconnect levers are available for both -MT screwdriver operation and -MTL finger operation. The -TG versions accept current CLIPLINE complete fuse plugs, component holders, disconnect plugs, and feed-through plugs. Like the standard PTFIX, a variety of mounting, color, and size options are available, but the PTFIX Function also includes 2.5 mm2 outputs with a larger 6 mm2 feed-in terminal. PTFIX Function is the newest product to feature Phoenix Contact’s popular Push-in Technology.

Phoenix Contact has added function blocks to its popular line of PTFIX distribution blocks. The new PTFIX Function features Push-in Technology that can connect, disconnect, and protect terminal blocks. Disconnect levers are available for both -MT screwdriver operation and -MTL finger operation. The -TG versions accept current CLIPLINE complete fuse plugs, component holders, disconnect plugs, and feed-through plugs. Like the standard PTFIX, a variety of mounting, color, and size options are available, but the PTFIX Function also includes 2.5 mm2 outputs with a larger 6 mm2 feed-in terminal. PTFIX Function is the newest product to feature Phoenix Contact’s popular Push-in Technology.

Powell Electronics supplies MTC6 thermocouple terminal blocks from TE Connectivity. The block is adapted to many types of thermocouples, allows thermocouple wire extension with no loss of signal integrity, and is compatible with solid type thermocouple wires. Only one part number is needed for all configurations. One thermocouple lead connects through one terminal block. The MTC6 requires only 6 mm of space, allowing 50 terminals per foot of rail.

Powell Electronics supplies MTC6 thermocouple terminal blocks from TE Connectivity. The block is adapted to many types of thermocouples, allows thermocouple wire extension with no loss of signal integrity, and is compatible with solid type thermocouple wires. Only one part number is needed for all configurations. One thermocouple lead connects through one terminal block. The MTC6 requires only 6 mm of space, allowing 50 terminals per foot of rail.

SCHURTER’s FPBB Rail features a compact dual-stage EMC filter that provides high performance with optional circuit protection, a fuse holder or circuit breaker for equipment, overvoltage protection, quick wiring with cage clamp terminal, and protection against interference voltage from the mains or power supply. FPBB is designed for electric switch and control cabinets. It is suitable for use in equipment according to IEC/UL 62368-1 and for use in medical equipment according to IEC/UL 60601-1 (1 MOOP).

SCHURTER’s FPBB Rail features a compact dual-stage EMC filter that provides high performance with optional circuit protection, a fuse holder or circuit breaker for equipment, overvoltage protection, quick wiring with cage clamp terminal, and protection against interference voltage from the mains or power supply. FPBB is designed for electric switch and control cabinets. It is suitable for use in equipment according to IEC/UL 62368-1 and for use in medical equipment according to IEC/UL 60601-1 (1 MOOP).

Molex DIN-rail or panel-mountable High-Current Universal-Clamp Terminal Blocks, supplied by Avnet, offer a versatile solution for high-current and voltage applications requiring aluminum-to-aluminum, copper-to-copper, or aluminum-to-copper terminations. Since industries are moving to smaller and smaller electrical components. Molex high-current universal-clamp terminal blocks achieve approximately 1/3 space savings compared to similar product from competitors. High-voltage, high-current applications require resistance to short circuiting to circumvent increasingly dangerous situations. These terminal blocks have been short circuit tested according to the stringent requirements of IEC standard EN 61238-1:2003. Rated to 1000 V (for less-demanding applications, a 600 V option is available), these parts are a great choice for use in railway systems, photovoltaics (solar), and ships.

Molex DIN-rail or panel-mountable High-Current Universal-Clamp Terminal Blocks, supplied by Avnet, offer a versatile solution for high-current and voltage applications requiring aluminum-to-aluminum, copper-to-copper, or aluminum-to-copper terminations. Since industries are moving to smaller and smaller electrical components. Molex high-current universal-clamp terminal blocks achieve approximately 1/3 space savings compared to similar product from competitors. High-voltage, high-current applications require resistance to short circuiting to circumvent increasingly dangerous situations. These terminal blocks have been short circuit tested according to the stringent requirements of IEC standard EN 61238-1:2003. Rated to 1000 V (for less-demanding applications, a 600 V option is available), these parts are a great choice for use in railway systems, photovoltaics (solar), and ships.

Phoenix Contact’s PT push-in connection terminal blocks, supplied by Allied Electronics & Automation, have been developed for direct conductor connection. This means that solid conductors or conductors with ferrules can be inserted directly into the terminal block without tools. The special spring profile enables the easy insertion of conductors with ferrules from 0.25 mm2. The contact spring is opened automatically when the conductor is pushed in and thereby provides the required pressure force against the current bar. Both for releasing conductors and connecting small cross sections from 0.14 mm2, the spring is opened by means of the actuation lever – easily and without direct contact with live parts. The actuation lever can be operated with all standard screwdrivers. The PT connection terminal blocks are subjected to tests which go beyond the basic terminal block standard, enabling them to be used in all sectors of industry, such as energy supply, transportation technology, process engineering, shipbuilding, and the chemical and petrochemical industry. The push-in connection technology is tested for maximum vibration and shock resistance. The test runs through a frequency range of 5 Hz to 150 Hz at a speed of up to 5.72 m/s2. The test objects are tested on each of the three axes (X, Y, Z). No contact interruptions > 1 μs are permitted during the test. Push-in connection technology meets these high requirements in terms of vibration and shock loads up to 350 g.

Phoenix Contact’s PT push-in connection terminal blocks, supplied by Allied Electronics & Automation, have been developed for direct conductor connection. This means that solid conductors or conductors with ferrules can be inserted directly into the terminal block without tools. The special spring profile enables the easy insertion of conductors with ferrules from 0.25 mm2. The contact spring is opened automatically when the conductor is pushed in and thereby provides the required pressure force against the current bar. Both for releasing conductors and connecting small cross sections from 0.14 mm2, the spring is opened by means of the actuation lever – easily and without direct contact with live parts. The actuation lever can be operated with all standard screwdrivers. The PT connection terminal blocks are subjected to tests which go beyond the basic terminal block standard, enabling them to be used in all sectors of industry, such as energy supply, transportation technology, process engineering, shipbuilding, and the chemical and petrochemical industry. The push-in connection technology is tested for maximum vibration and shock resistance. The test runs through a frequency range of 5 Hz to 150 Hz at a speed of up to 5.72 m/s2. The test objects are tested on each of the three axes (X, Y, Z). No contact interruptions > 1 μs are permitted during the test. Push-in connection technology meets these high requirements in terms of vibration and shock loads up to 350 g.

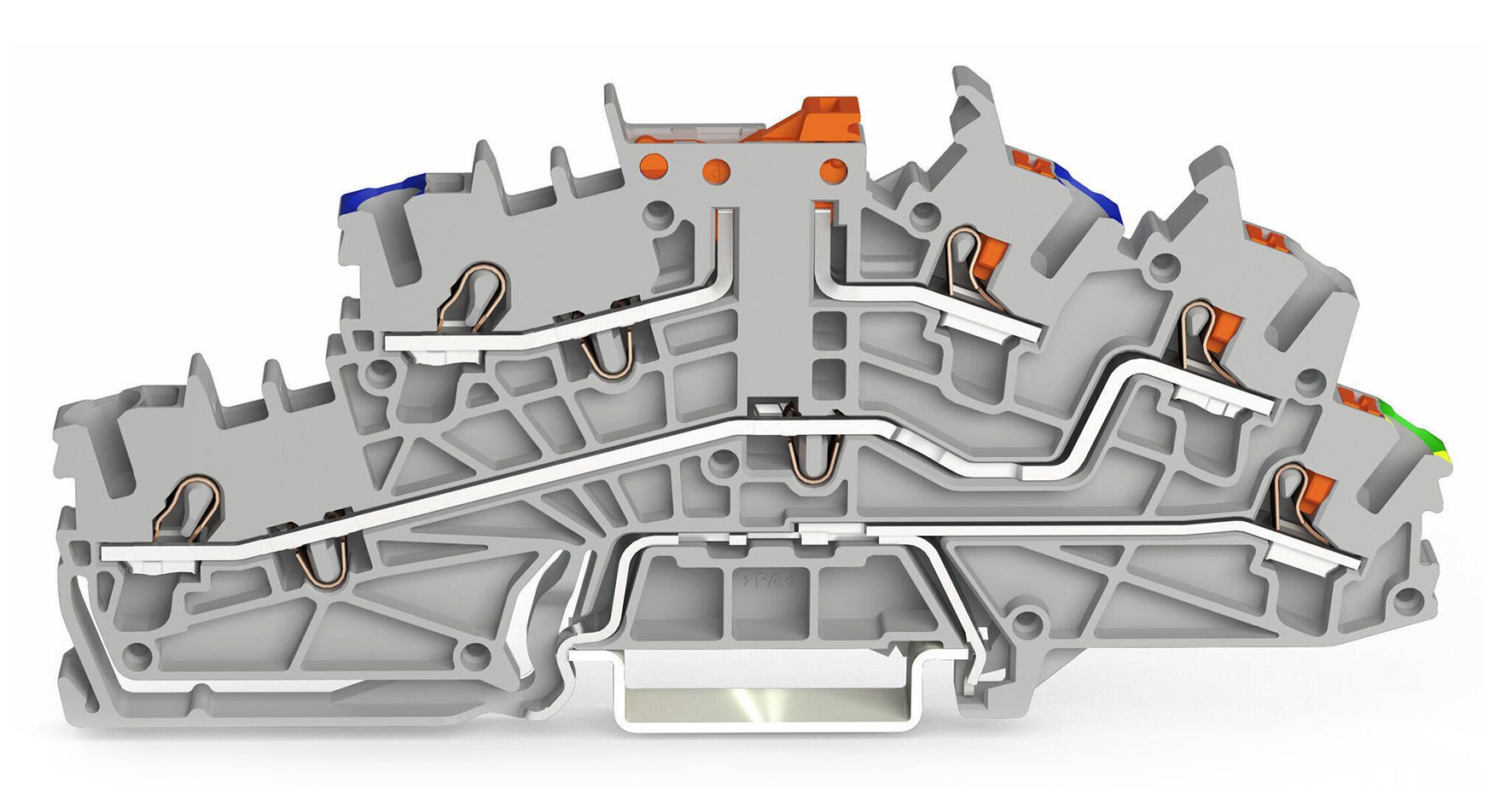

WAGO’s TOPJOB S multi-level installation terminals has expanded with the addition of push-button and hybrid variants. This offering allows for fusing or blade-style disconnect, as well as direct ground connection to the DIN rail, all in one terminal block. These terminal blocks are also available as a hybrid solution of the two actuation types, allowing users to choose which is best for field wiring. This product provides various terminal blocks in the same profile, giving assemblies a clean, seamless look and saving space in industrial applications such as process equipment.

WAGO’s TOPJOB S multi-level installation terminals has expanded with the addition of push-button and hybrid variants. This offering allows for fusing or blade-style disconnect, as well as direct ground connection to the DIN rail, all in one terminal block. These terminal blocks are also available as a hybrid solution of the two actuation types, allowing users to choose which is best for field wiring. This product provides various terminal blocks in the same profile, giving assemblies a clean, seamless look and saving space in industrial applications such as process equipment.

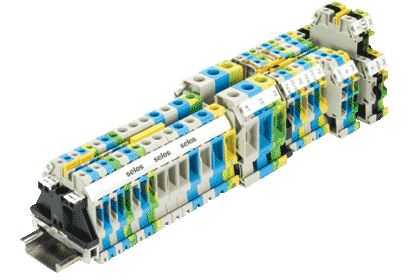

Wieland’s selos DIN rail terminal blocks are known around the world. The selos product range combines the advantages of a classic screw connection with modern connection technology. Selos features high performance with large connection capacity and high current-carrying capacity. The time-saving assembly offers pluggable jumpers (the Wieland jumper), and screw-less snap-in PE terminals. Uniform accessories provide cost savings for warehousing and logistics, delivering value for the customer and increased efficiency in wiring and logistics.

Wieland’s selos DIN rail terminal blocks are known around the world. The selos product range combines the advantages of a classic screw connection with modern connection technology. Selos features high performance with large connection capacity and high current-carrying capacity. The time-saving assembly offers pluggable jumpers (the Wieland jumper), and screw-less snap-in PE terminals. Uniform accessories provide cost savings for warehousing and logistics, delivering value for the customer and increased efficiency in wiring and logistics.

Find out more about connector products for industrial applications here and here.

Like this article? Check out our other Product Roundup, Product News, and Connector Industry News features and our 2022 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Mezzanine Connectors Product Roundup - April 16, 2024

- Out Now! New eBook Shares Bright Ideas for Electrification - April 16, 2024

- What are ARINC 801 Connectors? - April 9, 2024