Automation Means a Bright Forecast for Industrial Connectors

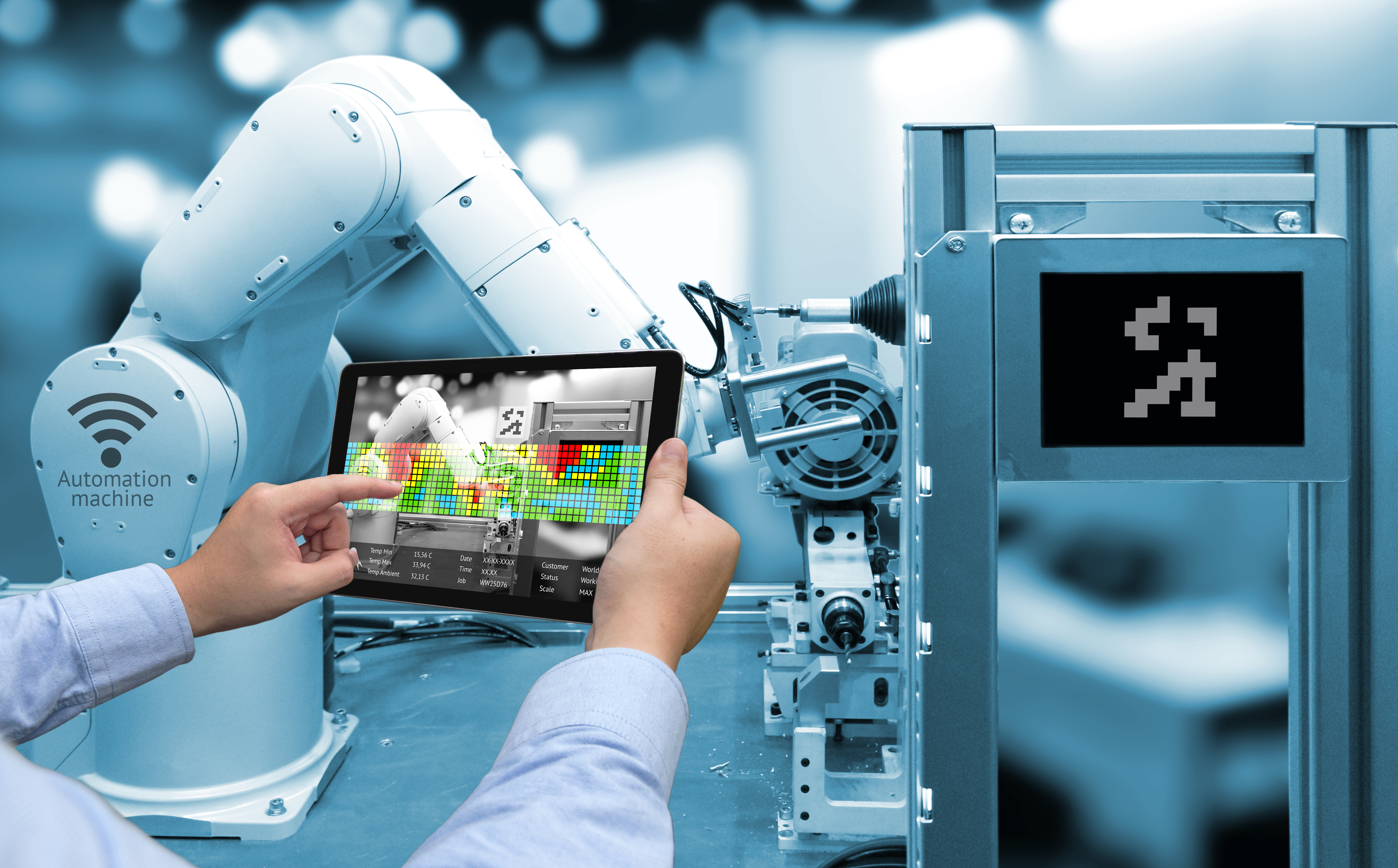

The industrial world has made the transition from mechanical control to electronic control, and now we are in the middle of the digital transformation. A new report by Bishop & Associates examines the market for industrial connectors and how the rise of smart cities, smart factories, and the smart grid will impact this category of connectors.

Connectors designed for use in industrial markets come in a range of shapes and sizes and are subject to a variety of standards and norms, depending on the type of application, the end-use equipment market, the region, etc. These applications typically include industrial “factory floor” environments, but also electrical power generation and distribution, machinery, mining, geophysical exploration and heavy construction, and farming equipment.

Connectors designed for use in industrial markets come in a range of shapes and sizes and are subject to a variety of standards and norms, depending on the type of application, the end-use equipment market, the region, etc. These applications typically include industrial “factory floor” environments, but also electrical power generation and distribution, machinery, mining, geophysical exploration and heavy construction, and farming equipment.

Industrial connectors fall into two basic classes. On one hand, there are the (circular and rectangular) connectors defined by military specifications. These interconnects are intrinsically resistant to mechanical abuse, and many include interfacial and wire seals to maintain the integrity of the electrical interface. They are built in accordance with and conform to MIL specs such as circular MIL-DTL 5015, MIL-DTL 38999, and rectangular MIL-DTL-24308. On the other hand, commercial-grade connectors have been adapted to industrial environments, with the addition of seals, improved contact design, and tougher or new materials to withstand challenging environments.

These days, environmentally sealed connectors, fit or used in harsh environments, are available for nearly all types of applications in a variety of end-use markets, including input/output (I/O), power, and signal. They take the form of circular, rectangular, cable and panel-mounted, board-to-board, mezzanine, and even coaxial RF connectors. New connectors of every style continue to enter the market with innovative hermaphroditic or elastomeric contacts.

Although most of these industrial interconnects and interfaces are based on copper conductors, optical fiber has begun to infiltrate specific markets like factory automation networks and “big data” applications, due to its specific characteristics, which include high bandwidth and immunity to EMI.

Commercially available connector types such as RJ45 and USB were used to developed industrial environment equivalents that are fully intermateable with the consumer models. At the same time, military-type connectors are made compatible with commercially available types (COTS), reducing the cost price and increase availability.

Consequently, the number of connector suppliers participating in this market continues to grow, despite a degree of consolidation as a result of ongoing mergers and acquisitions. But as new requirements and applications arise, and new technologies are being developed, new suppliers enter the industrial market.

Leading Connector Manufacturers in the Industrial Market

The global industrial market for connectors is expected to see mid-single-digit growth over the five-year period 2018 through 2023, approaching $11 billion in 2023. While growth in this market is expected to slow over the coming three years, it is forecasted to pick up a higher growth rate again from 2022 onwards.

Five-Year CAGR by Region for the Industrial Market

for Connectors 2018E through 2023F

We anticipate the Industrial Internet of Things to continue to have a positive impact on factory automation, adding growth to the Industrial Automation and Process Control segment, as well as the Machine Tools, Machinery, and Robotics segment. With automation being a long-term trend in the industry, robotics will see extensive growth. The Energy segment has already enjoyed a growth spurt by the (partial) implementation of the smart grid in many countries and regions and it will continue to be driven by the development of new or additional alternative energy sources. Based on this, we forecast that the Energy segment will be the third fastest-growing segment with a five-year CAGR in the mid-single digits.

For a more detailed analysis of industrial connectors, please visit Bishop & Associates Inc. to obtain the new research report, World Industrial Market for Connectors 2019. This in-depth, 269-page report includes a look at connector design and manufacturers; cable assemblies; sales and growth forecasts from 2018-2023; market trends and statistics; regional analysis; equipment using connectors in automation and process control; communication protocols used in industrial applications; critical connector performance attributes; IIoT communication and networking; energy applications; smart buildings and cities; and much more.

No part of this article may be used without the permission of Bishop & Associates Inc. If you would like to receive additional news about the connector industry, register here. You may also contact us at [email protected] or by calling 630.443.2702.

Like this article? Check out our other 2019, Industry Facts & Figures and Industrial Market articles.

- The Industrial Market for Connectors in a Changing World - April 20, 2021

- How Key Trends in the Transportation Market Will Impact Electronics Growth - March 17, 2020

- Automation Means a Bright Forecast for Industrial Connectors - February 19, 2019