What are ZIF and LIF Connectors?

Meet the Connector: ZIF and LIF Connectors

Zero insertion force and low insertion force connectors protect the IC from damage during mating and unmating.

ZIF (Zero Insertion Force) and LIF (Low Insertion Force) connectors are used in electronic devices such as computer hardware, medical devices, robotics, and many other applications between two components, such as integrated circuits (ICs) and printed circuit boards (PCBs). These two related connectors make it easier to connect or remove components without applying excessive force, reducing the risk of damage to the components or the PCB.

The ZIF connector was developed in the 1970s by AMP Incorporated (now part of TE Connectivity). AMP introduced ZIF connectors to solve the problem of damage, which commonly occurred when users made connections between electronic computing hardware, which was beginning to proliferate among a wider variety of users with varying skill levels. ZIF connectors greatly improved the reliability and ease of use of connectors at a critical point in the evolution of computing.

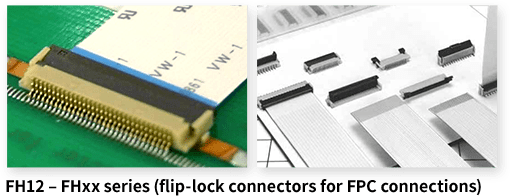

The LIF connector came next. Several companies, in particular Hirose Electric, developed this variation to address some of the limitations of traditional high-insertion force connectors. While ZIF connectors require “zero force” during initial insertion, LIF connectors still require some force but significantly less than standard connectors. The reduced force is important to prevent damage to delicate components and PCBs.

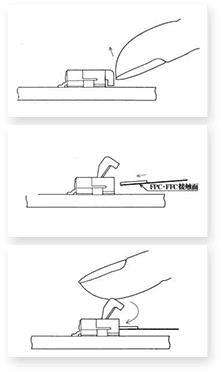

Hirose developed a new “flip-lock” ZIF (Zero Insertion Force) design in which the connector’s top is opened to insert the FPC, making the connection process easier (see the figure below).

ZIF and LIF connectors are still widely used today.

Design Notes

Use guidance:

ZIF connectors require zero force during the initial insertion of a component. They typically have a hinged or sliding mechanism that allows the user to open and close the connector without applying pressure. To make a secure connection, open the connector, gently place the component into the socket, and then close the connector, which clamps the component’s leads or pins securely in place.

LIF connectors require a low level of force for insertion and removal compared to traditional connectors, but they are not “zero force” like ZIF connectors. They still reduce the risk of damaging the component or PCB. LIF connectors are often used in situations where the component needs to be securely connected but may also need to be removed or replaced occasionally.

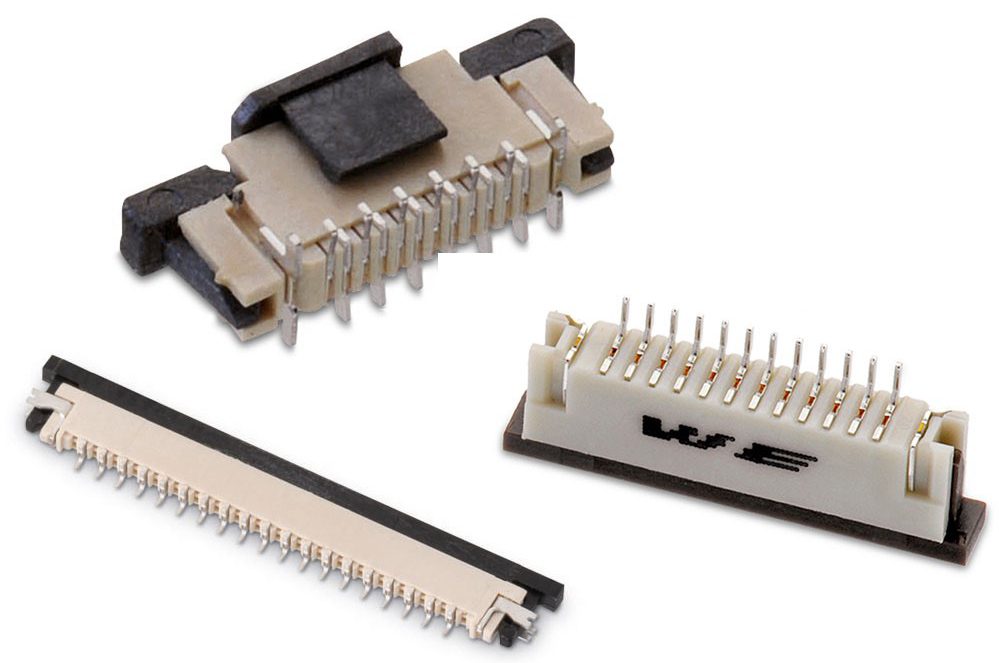

Würth Elektronik’s WR-FPC series ZIF and LIF connectors, available from DigiKey

Cable considerations: ZIF connectors are often used for connecting flat flexible cables (FFCs) or flat ribbon cables to PCBs.

Markets and Applications:

Computing (3C), Medical, Automotive, and many other markets

ZIF and LIF connectors can be found in various electronics, including laptops, smartphones, and other consumer electronic devices, as well as medical devices, automotive applications, screens and displays, and applications where frequent component insertion and removal is required, such as Test & Measurement and debugging equipment.

Suppliers

Amphenol Communications Solutions, Greenconn, Hirose Electric, Kyocera AVX, JAE, Molex, TE Connectivity, Würth Electronik

Related Products

Like this article? Check out our other Meet the Connector and Networking articles, our Medical Market Page, and our 2023 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024