Industrial Laser Processing Fuels Today’s Modern Electronic Devices

Automated manufacturing processes are integrating industrial lasers for precision processing, inspecting, and testing of materials. Fiber optic connectors help make these systems possible.

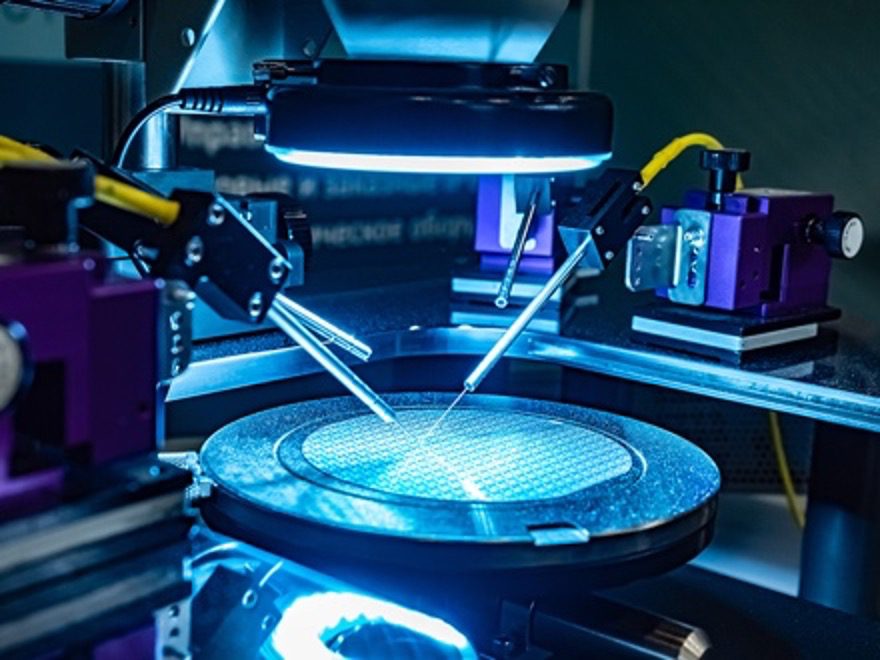

(Image courtesy of Teradyne)

Fiber optic technology is enabling a new generation of high power, ultrafast industrial lasers. These precision beams of light are used in testing, inspection, and processing, making the production of components and equipment faster and more efficient, and expanding capabilities for testing labs and manufacturers.

Lasers emit light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The most common laser technologies include CO2 lasers, fiber lasers, solid-state lasers, diode lasers, infrared (IR) lasers, and ultraviolet (UV) lasers. Fiber optic technology is used to transmit information as pulses of light through tiny strands of fiber made of glass or plastic. Optical fibers are about the diameter of a strand of human hair and when bundled into a cable, they’re capable of transmitting light (laser beams) or data over longer distances and faster than other mediums. Fiber optic cables are comprised of hundreds of optical fibers bundled within a plastic casing, and since they are non-metallic, they are not affected by electromagnetic interference. Fiber cables are also much safer than electrical cables, as they do not carry a current and therefore cannot generate an electrical spark.

Automated precision laser processing has enabled semiconductor and automated test equipment manufacturers to address the capacity shortage. The ability to perform high-volume, production-level semiconductor processing and testing quickly, efficiently, and accurately in an automated fashion is crucial to support the growing number of electronic devices which use integrated circuits (ICs). 5G has created increased semiconductor demand from industrial, telecommunications, consumer electronics, automotive, aerospace and defense, medical, and other high growth industries.

At Polymicro Technologies, a Molex company, glass fiber is drawn vertically directly from a furnace to make fiber optical tubing, sheets, or rods with a uniformed cross section. Large tubing can be formed by extrusion or casting. Polymicro Technologies manufactures multimode optical fibers and bundles, fused silica capillary tubing and assemblies, micro components, industrial laser solutions, and sterilized optical fiber probes for medical applications. Small tubing is typically manufactured by drawing or pulling a larger cylinder of semi-fluid glass down to the desired specifications. Fused quartz or synthetic fused silica tubing is more challenging to draw than borosilicate glass, because of the high temperature requirements. Temperature and draw speed must be precisely controlled to maintain dimensions. To put it in perspective, some glass will soften at 500 °C (900 °F), while others only soften above 1,650 °C (3,180 °F). Either way, pretty hot.

Amphenol developed the first fiber optic industry standard connector, the SMA. This connector is still used in laser technologies today. SMA connectors serve applications in the industrial, medical, telecom, and other markets.

Amphenol Aerospace offers multimode fiber optic connector and cables for lasers and high-speed telecommunications. These products comply with industry standards for optical transmission loss, reflectance, visual end-face specifications, and geometry, and MIL-Spec optical products are also available.

Amphenol ST and STII connectors, available from Mouser, (left) utilize a bayonet style mating system to provide a secure coupling mechanism. Amphenol small form factor (SFF) connectors (right) utilize the familiar RJ45 latching mechanism to provide tactile and audible mating recognition for a safe and reliable connection.

Timbercon, a Radiall company, designs and manufactures high-reliability fiber optic, hybrid and laser cable assemblies for the military, aerospace, datacom, medical, and industrial markets.

LEONI offers fused silica fiber optic interconnect and cable solutions for laser beam transmission used in industrial and medical lasers. The product offering includes high-power semiconductor lasers, solid-state lasers, and fiber lasers with a broad selection of F-SMA and SMA905 connectors. Copper alloy ferrules (CuSMA) provide outstanding fiber alignment, heat dissipation and fiber centration.

Industrial Lasers Optimize In-Line Automated Optical Inspection Industry 4.0 Equipment

PCB inspection is a critical process of pick-and-place machines. Manual inspection is unreliable, inconsistent, and too slow, making automation with lasers essential. Automatic optical inspection (AOI) is widely used in most production level PCBA pick-and-place manufacturing systems for inspection but achieved automatically. This provides a high degree of repeatability and is particularly fast and useful when situated at the end of a line producing soldered PCBAs, where it can quickly identify defects and component orientation. AOI testing typically uses LED, infrared (IR), or ultra-violet (UV) lasers to identify defects. Some systems use X-ray technology.

Test Research Inc. of Taiwan is well-known as one of the leading PCBA test and inspection systems providers for the electronics manufacturing industry and now offers two new Automatic Optical Inspection (AOI) solutions, which are IPC-CFX compliant, the 3D AOI TR7700Q SII and the 3D AOI TR7700 SIII. The AI-powered 3D AOI TR7700Q SII is a high-accuracy, high-speed AOI platform and the TR7700 SIII provides optical and blue-laser-based 3D measurements for optimum automated defect identification.

IPC-CFX, an international standard issued by IPC Association Connecting Electronics Industries, is at the foundation of the Factory of the Future, a plug-and-play solution that simplifies and standardizes machine-to-machine communication while also facilitating machine-to-business and business-to-machine applications. IPC-CFX is based on the IPC-2591, Version 1.3 Standard (released in February of 2021) and the Connected Factory Exchange (CFX), which are both managed by the IPC Connected Factory Initiative Subcommittee.

To learn more about the organizations featured in this article, visit the Preferred Supplier pages for Amphenol Aerospace, IPC, Molex, Mouser Electronics, and Radiall.

Like this article? Check out our other fiber optic, and circular connectors articles, our Industrial Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.