Rugged Active Optical Cables: A Viable Alternative to Copper and Fiber Optic Cable Assemblies

Copper and fiber optic cable have long been the go-to options for a variety of applications, but they fall short in harsh environments. RAOCs combine the benefits of each for an optimal, real-world solution.

Typically, in harsh environments such as industrial production facilities, refineries, process manufacturing plants, commercial aircraft, and even the far reaches of space, the cable solutions used to connect two pieces of electronic equipment are either copper or fiber optic cable assemblies. These are both very common, viable, and proven options. However, each comes with its own set of limitations regarding data rates, distance, and weight, and the ability to reliably operate in environments with hazards including dust, dirt, moisture, shock, vibration, and temperature extremes. Rugged active optical cable (RAOC) solutions combine the best of both worlds: the familiarity, ruggedness, and ease of use of copper connectors with the bandwidth and distance capabilities, and weight and space savings of fiber optic cable assemblies.

Copper Cable Assemblies

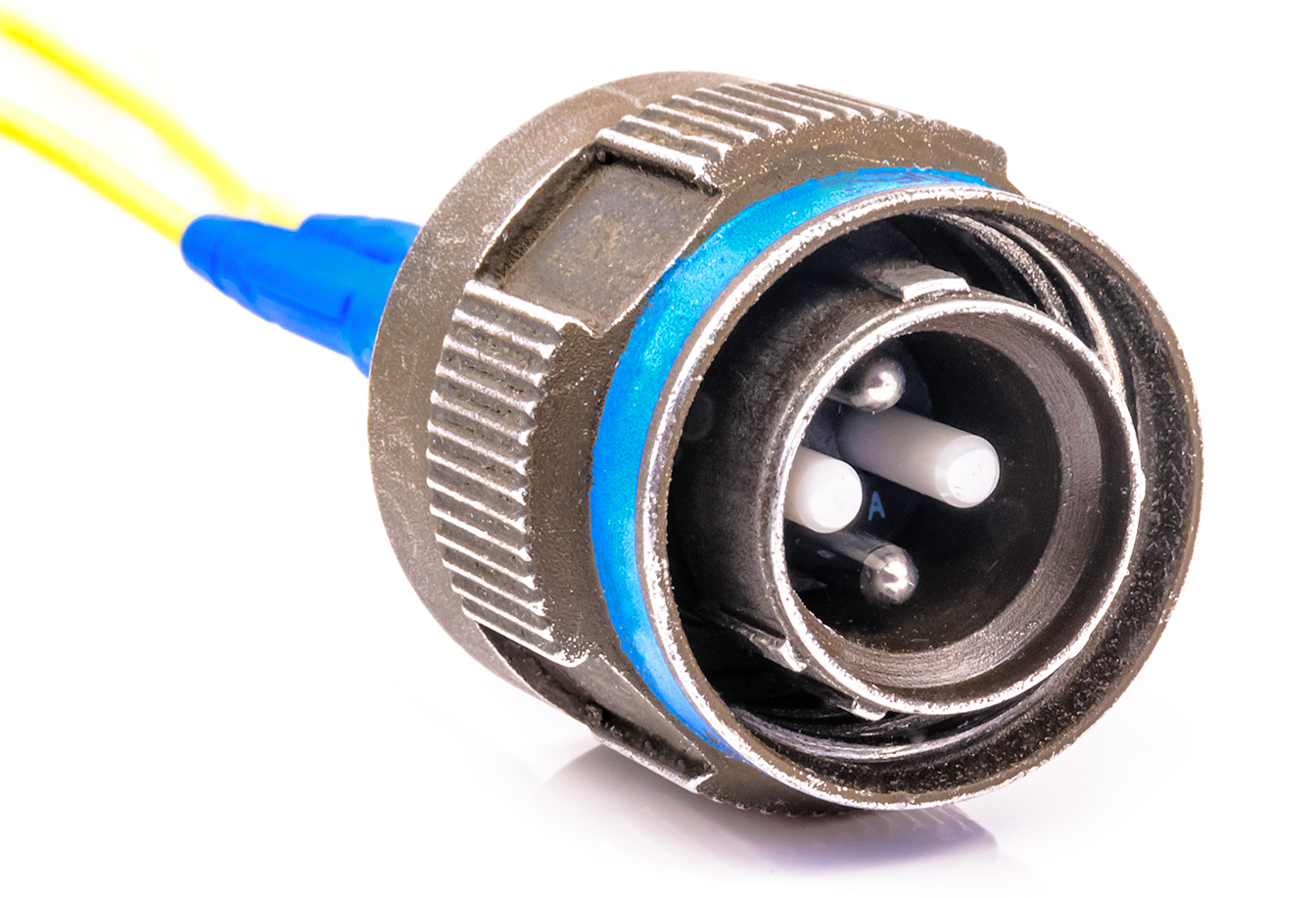

One of the main reasons copper cable assemblies are so widely used is their reputation for ruggedness and reliability, especially at the connector interface. Copper connectors designed for rugged applications have multiple points of contact, which makes them ideally suited for use in high-vibration harsh environments. Their familiarity and ease of use in the electronics industry, compared to fiber, also make them a popular option. With copper, installers simply plug in the cables, taking only a small amount of precaution to ensure that the connector interface is damage-free and free of foreign object debris (FOD). Another advantage of copper cable assemblies is that, at an overall system level, the costs tend to be lower than an equivalent optical-based solution. On the flip side, copper assemblies are bulky and heavy, are not suitable for supporting higher data rates for lengths beyond 3 to 4 meters, and require additional protection, such as shielding, to maintain the integrity of the electrical signal in environments with high electromagnetic interference (EMI).

Rugged copper cable assemblies like this one, which features AirBorn’s rugged, high-density, and high-speed verSI Series connectors, are widely used for their ability to operate reliably in high-shock, high-vibration, and high-dust environments but are limited to maximum cable lengths of 4m for high-data-rate transmission, are heavy and bulky, and take up valuable space.

Taking space flight as an extreme example, the cost to send one pound of cargo into space ranges from $20,000 to $50,000. Reducing the volume and weight of the cables within satellites and launch vehicles can allow for more cargo-carrying capacity. Aircraft, helicopters, air taxis, and industrial drones are other applications that can benefit from cable assembly volume and weight reductions.

Fiber Optic Cable Assemblies

Fiber optic cable assemblies overcome the size, weight, and length shortcomings of copper cable assemblies. They are much thinner and lighter than copper cables and can reliably transmit high data rates across much longer distances. Optical signals can travel up to 100m over multi-mode optical fiber cables at data rates that far surpass copper cables and, unlike the electrical signals transmitted over copper cabling, are immune to EMI. They do, however, introduce other concerns. Fiber optic cable assemblies utilize glass fiber terminations that are extremely sensitive to fingerprints, dirt, dust, oil, mud, and water. Well-sealed interfaces effectively maintain FOD-free connections post-installation, but any in-field maintenance or repair will expose the sensitive fibers to environmental hazards that could diminish performance.

Fiber optic cable assemblies maintain reliable connections as long as the connectors are mated. However, if the connection is broken for maintenance or repair, significant care is required to ensure that the faces of the fiber optic termini are clean and free from contaminants.

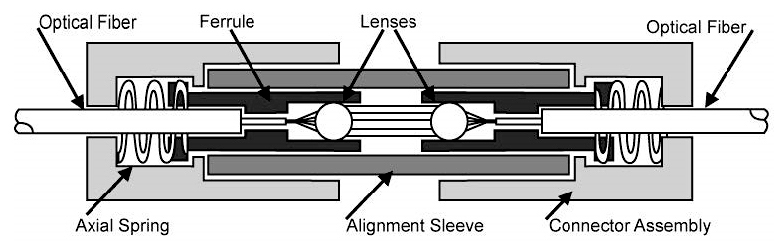

Fiber optic connectors with expanded beam termini are a better option in harsh, dusty, dirty environments than those with traditional physical contact fiber termini. Expanded beam fiber optic connectors utilize a lens to expand and collimate (i.e., accurately align) the light beam emitted by optical fibers and transmit it through a tiny air gap to a mating connector, where the light is collected and focused by a second lens into a second optical fiber to complete the connection. Greatly increasing the beam diameter makes these connectors less sensitive to the intrusion of small contaminant particles that could completely obscure transmission in physical contact fiber optic connectors.

Expanded beam fiber optic termini expand the optical signal with a lens at the tip of the transmitting fiber, send the signal over a small air gap to the mating connector, and then collimate the signal using another lens at the tip of the receiving fiber. This process makes the optical signal much less sensitive to small particles of dust or other contaminants and eases cleaning and maintenance requirements. For more information, please reference this Optokon article.

According to Bishop & Associates, fiber optic connectors account for roughly 3 to 5% of all connectors in the traditionally harsh-environment industrial and military markets. Although that figure will continue to rise, users currently in the field are generally not as familiar with fiber optic connections as they are with copper connections and may not take the appropriate level of precautions when unmating and mating fiber optic connectors in dusty, dirty, muddy, and wet environments. In addition, fiber optic cable assemblies require engineers to design transceivers into their equipment to convert electrical signals to optical signals and vice versa on the receiving end, which further increases the complexity and costs of the equipment while taking up valuable PCB space and system power.

Active Optical Cable Assemblies

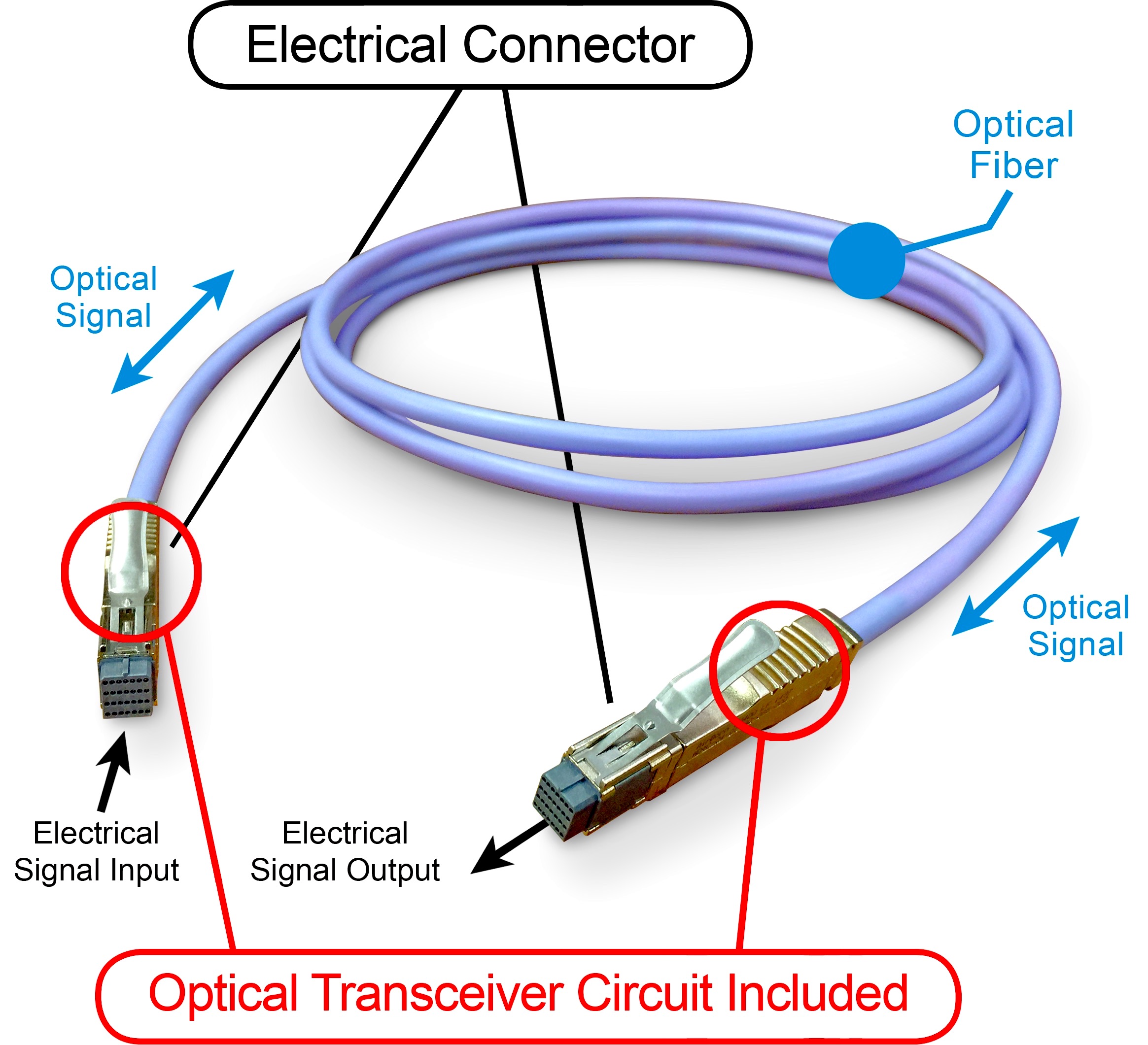

Enter active optical cable (AOC) assemblies, which effectively combine the benefits of copper and fiber optic cable assemblies. In AOC assemblies, the ends of fiber optic cables are terminated with traditional copper connectors, the electrical signals from which are converted to optical signals via optical transceiver circuits integrated within the connectors, routed across up to 100m of standard multi-mode fiber, and then converted back into electrical signals via the optical transceivers built into the copper connectors on the opposite end.

AOC assemblies have the electrical interface of a copper cable assembly and the optical cable of a fiber optic assembly. Both ends of an AOC assembly are copper connectors with integrated transceivers that convert electrical signals to optical signals and vice versa.

Commercial-grade AOCs are widely available in today’s market but are most commonly used within data centers to connect servers and networking equipment when distances exceed the limitations of copper cables. This is because data centers have tightly controlled operating environments and commercial-grade AOCs simply aren’t designed for use in harsh environments like oil refineries, chemical plants, aircraft repair and maintenance hangars, or battlefields.

Now, though, rugged and even space-grade AOC options are available from suppliers that specialize in developing effective electronic solutions for the world’s toughest environments.

Rugged Active Optical Cable Assemblies

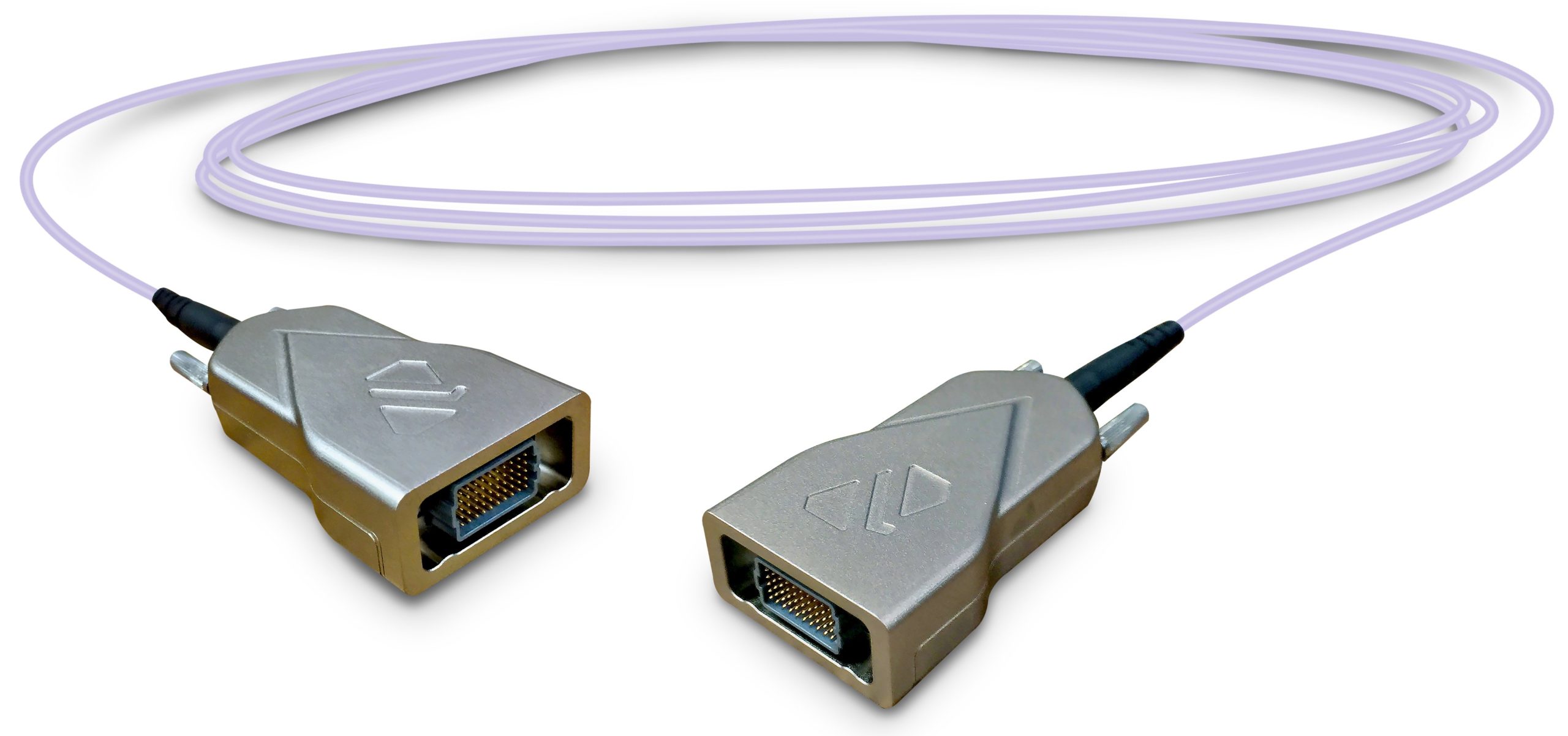

Rugged active optical cable (RAOC) assemblies especially designed to handle hazards including high shock, high vibration, and extreme temperatures in harsh environment applications were recently introduced to market. These ruggedized and even space-grade AOCs offer the same optimal combination of copper and fiber optic cable benefits as commercial-grade AOCs but are expertly engineered to operate reliably in the harshest environments, including downhole applications, satellites, construction equipment, industrial plants, and battlefield vehicles and equipment.

AirBorn’s new SAOC® Space-Rated Active Optical Cable Assembly is the first AOC technology especially designed for the harsh environment of space. AirBorn’s RAOC® Rugged Active Optical Cable Assembly is an offshoot of the SAOC developed for rugged, non-space environments and combines the ruggedness and reliability of AirBorn’s high-density verSI Series copper connectors with the size, weight, and data rate benefits of fiber optic cable.

RAOCs can also support greater design flexibility within harsh-environment product architectures. Design engineers who utilize AOCs can design a box or piece of equipment that readily accepts copper cable assemblies and active optical cable assemblies if they utilize the same pin-outs. This approach simplifies the design process by allowing the same device to be equipped with either cabling technology in the field — an option that has traditionally required engineers to design, build, and install two different boxes. Users could, for instance, install copper cable assemblies for shorter run applications and then easily swap those out for rugged AOCs if application demands change and require either longer runs or other factors, like space and weight restrictions that make AOCs a better option.

In addition, many rugged AOCs are available with a wide variety of connector options, which further expands design flexibility. RAOCs can be equipped with Micro-D connectors, Nano-D connectors, or micro-circular connectors to achieve an array of different size, weight, and performance benefits. Hybrid versions, such as a Micro-D connector on one end and a standard 38999 circular on the other end, or even designs that combine power with fiber, are also possible.

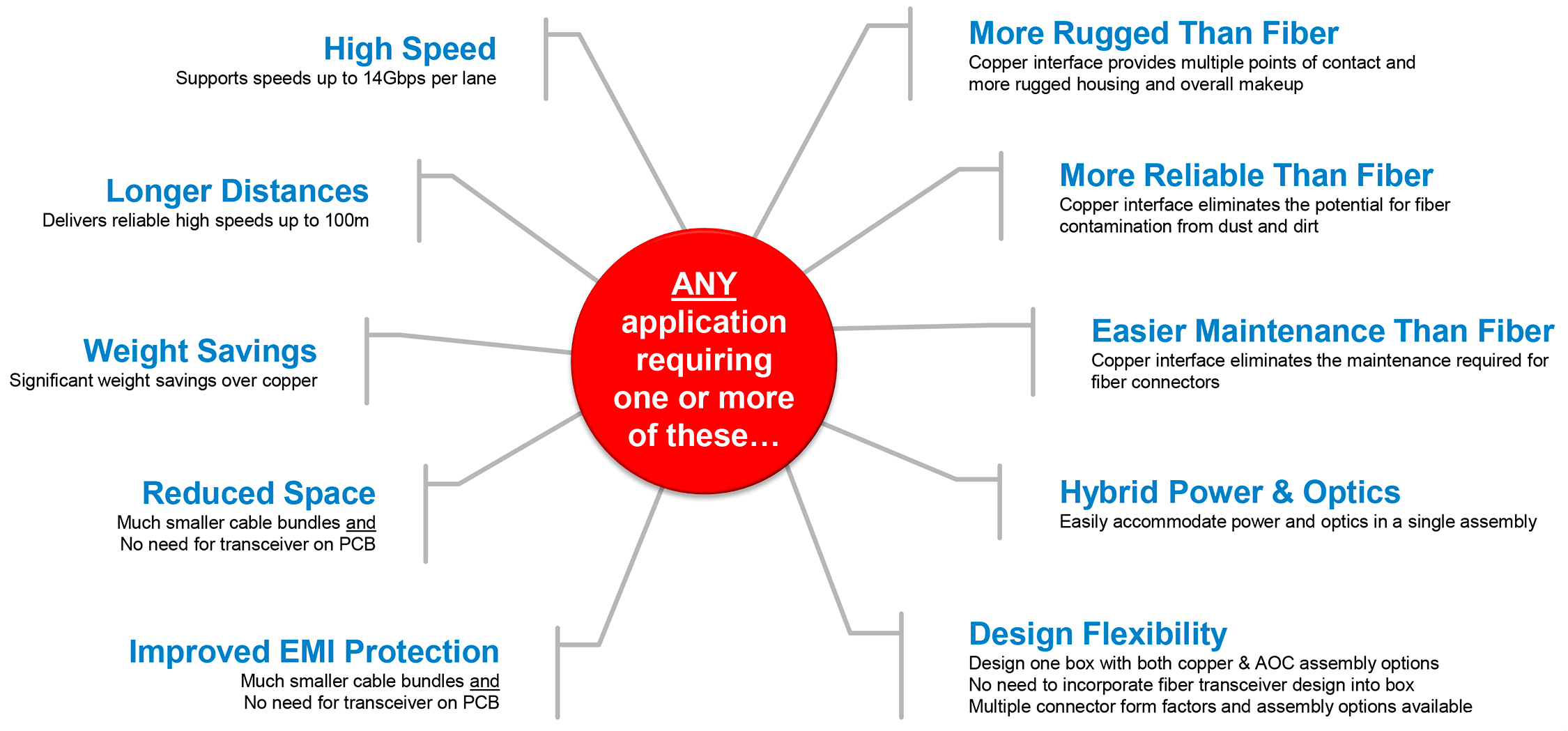

This diagram illustrates the many application requirements that an AOC or RAOC might address more effectively than either a copper or a fiber optic cable assembly. For assistance identifying the right cabling solutions for your specific application, contact AirBorn’s team of experienced Solution Engineers.

Rugged AOCs effectively combine the best, most beneficial characteristics of copper and fiber optic cable assemblies. They provide the space, weight, and length benefits of fiber, without the termination or maintenance challenges, in addition to the proven ruggedness, familiarity, ease-of-use, and affordability of copper. They offer attractive connectivity solutions for a wide range of harsh-environment applications. So, rugged AOCs are definitely worth considering for your next harsh-environment electronic equipment design. Just be sure to work with a supplier proven to be well-experienced in overcoming the unique challenges of harsh-environment designs in order to avoid commercial-grade AOCs that have been repackaged and marketed as rugged. Trusted suppliers should offer strong supporting test results and other documentation that clearly demonstrates the inherent ruggedness and reliability of their AOC solutions.

For more information, visit AirBorn online.