New Circular Connectors Add to Multi-Billion Dollar Market

One of the earliest and most popular types of connectors continues to see design refinements and innovations. An examination of the huge circular connector market finds that commercial and industrial types are most specified in MIL/Aero applications. Creative COTS are used everywhere.

There is not an industry today that isn’t designing equipment to be smaller, lighter, more reliable, and with increased functionality. Circular connectors are in the forefront of these new applications. Families of standardized circular connectors alone had worldwide sales of over $5,800 million in 2022 with a CGR exceeding most industries. Over 20% goes through distribution. When you add-in cables, application-specific customs, adapters, and accessories such as end caps and backshells, circular connectors represent a huge marketplace that provides work for many of us either producing, selling, or putting them to use.

Circular connectors are used almost everywhere, from wearable medical and MIL sensors, push-pull test equipment, space umbilicals, rugged truck-trailer interconnects, to M2M industrials, entertainment microphones, and many other applications. Miniaturization of connectors, including circulars, follows the results of Moore’s Law for the constant scale reduction of electronic packaging.

Industrial, sensor & medical types

The M Series is primary for M2M, sensors, and instrumentation, where M8 and M12 traditionally are the most popular sizes. New combination layouts involve various contact sizes for signal and power, and even fiber and coax. Suppliers have begun offering the smaller, thread-locking M5 per IEC 61076-2-105 for portable and miniaturized applications where space is limited. Lighter weight is critical in industries such as defense & security, aerospace, instrumentation, testing equipment, civil or military unmanned aerial vehicles (UAVs). New and larger M40 and M58 sizes are being seen for high power and combination layouts.

M5 by Amphenol LTW features 4 pos.,1 amp per contact (left). M58 by Smiths Interconnect features 4 pos.,165 amp per contact, 650 Vrms (right).

The drive for new smaller and higher density M Series versions results from the expanded use of sensors – reflecting a growing need for data acquisition and transmission – plus the ongoing size reduction of electronic components combined with increased power needs.

By sheer quantities, push-pull types dominate the commercial and industrial circular connector markets, per Bishop & Associates’ recent report, “World Circular Connector Market 2023.” Push-pull includes a wide variety of connectors for medical equipment, Test & Measurement, instrumentation, entertainment systems, and others.

Available from Mouser Electronics, LEMO’s new robust push-pull 1S.275 Series for 12G-SDI (Serial Digital Interface) 4K UltraHD transmission is compliant with the SMPTE ST 2082-1 standard. Its external knurled surface is often referred to as a “chocolate bar” finish with its half-moon inserts. The shape is used to provide a secure grip and is used on most LEMO plugs.

At left are LEMO’s new 1S275 connectors for HD transmission, available from Mouser. Right is the B Series, keyed, with 8 sizes and up to 64 contacts, primarily for medical applications, available from PEI Genesis.

New mil-aero circulars

Strong interest in the MIL/aerospace industry focusing on SWaP-C (Size, Weight, and Power) prompted the creation of a multi-source standard to cover miniature versions of popular Series III MIL-DTL-38999 connectors, resulting in the new MIL-DTL-32689. The latest version, with Amend. 2, is dated January 2023, but the spec is still being finalized and there is no QPL at this time. Interestingly, for contact sizes 20HD and 23 (for wire sizes 20 to 30), the spec does not reference MIL or SAE or DSCC drawings, but rather vendor-specific part numbers. Existing versions include Amphenol Aerospace’s 2M, ITT Cannon’s MKJ Series, Glenair’s Mighty Mouse, and Souriau’s micro38999. Brett Cohen, national sales manager for specialty MIL manufacturer TopFlite Components, reports that the company has been doing equivalent M&M connectors for over 5 years.

Projected significant marketplace growth for MIL-DTL-32689 types and alternate equivalents has prompted the creation of several new connector series, including those from:

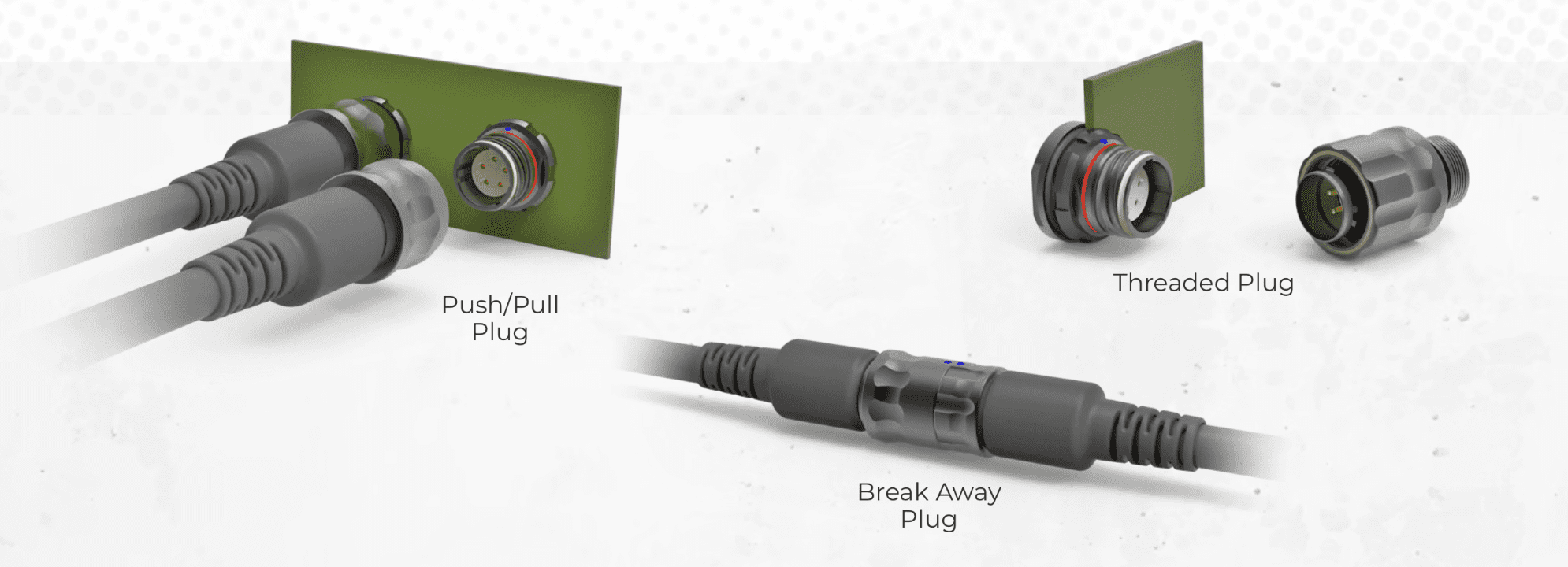

AirBorn, which is known for rugged and hi-rel rectangular and Micro/Nano connectors and cable assemblies, plus some circulars such as the small-size 360 Series, has produced the new TriMate family, which features a common receptacle to mate with three different plug types (ratchetting threaded, push-pull, and breakaway). With potentials for expansion, TriMate was released with multiple arrangements in two shell sizes with contact sizes 22D, 20MD, and 16.

The new TriMate family from AirBorn

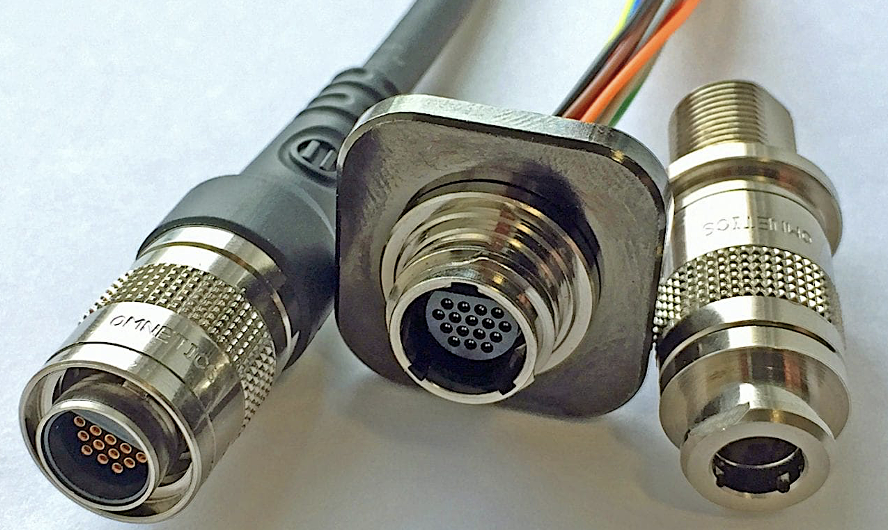

Omnetics Connector Corporation, well known for its smaller micro and nano connectors and harness assemblies, has released its Kilo 360 Series, featuring versions with both double-start and triple-start threads plus push-pull breakaway. Omnetics can provide a detailed qualification test report by Contech Research (founded by industry test standards expert Max Peel and now run by his son Tom Peel).

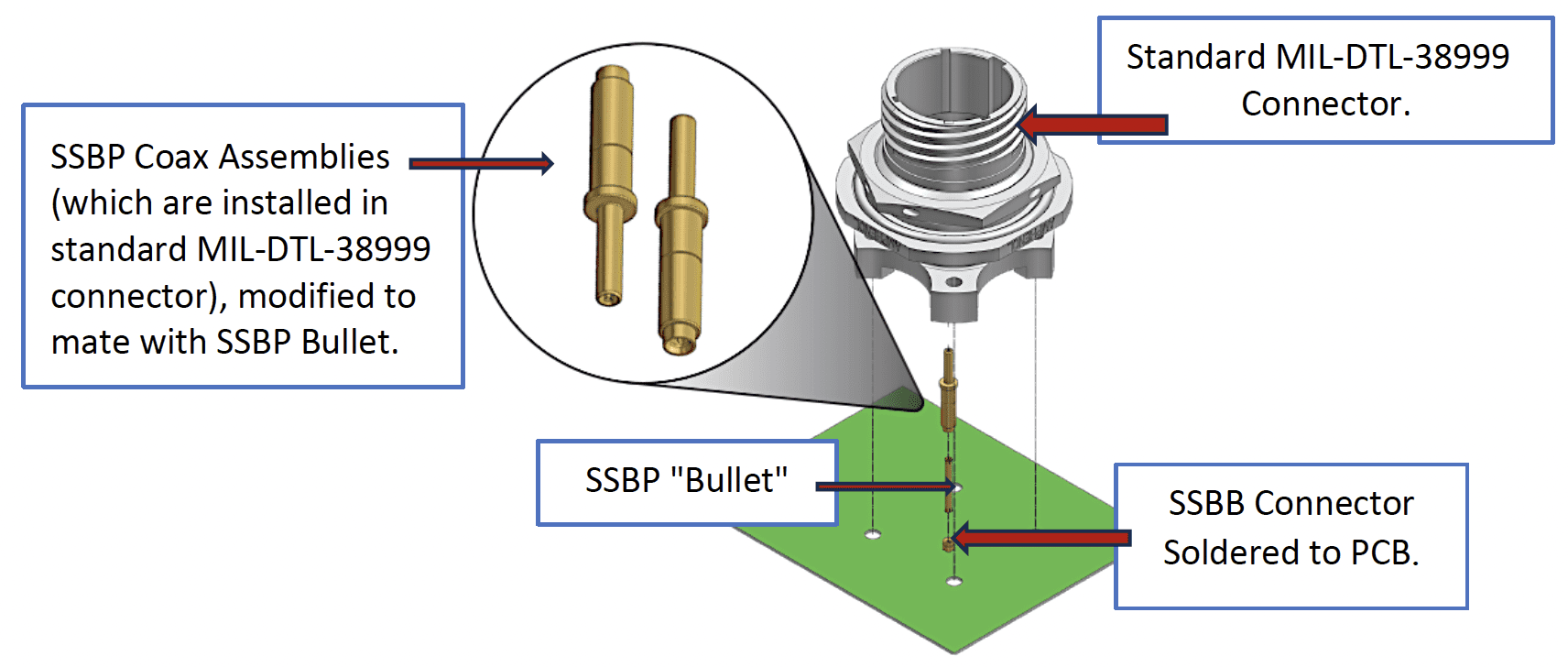

Today’s communications discussions focus on 5G and future 6G systems, which involves moving from 4G-LTE with 450 MHz up to 6 GHz (flexible bandwidths can go to 20 MHz), into increased work with V-band (50-75 GHz), E-band (60-90 GHz), W-band (75-110 GHz), and even D-band (110-160 GHz) for processing, transmission, and other needs. To support these frequencies, Southwest Microwave Inc. (SMI) recently expanded its family of SSBP coaxes that fit in contact cavities of standard MIL-DTL-38999 Series I, II, III, and IV receptacles, to include a new SSBP Bullet to mate with the company’s SSBB SMT board receptacles. SMI also has coaxes to fit the contact cavities for contact sizes 20 and 20HD in MIL-DTL-32689 and COTS-equivalent connectors.

The D38999 connector with SSBP-Bullet-SSBB stack-up is illustrated below. Latest shipments provide performance for 90 GHz. Holger Stuehrmann, VP and GM, adds that SMI’s simulation software can provide board launch design for customers, including 90° routing.

New microwave/mmWave connectors are round in shape, but RF is not included in market forecasts for circular connectors. (Refer to Bishop & Associates; report “World RF Coax Connector Market 2023” for latest information.)

For gains in functionality, new miniature combination-layout and modular connectors are being produced. Micro-miniature circulars based upon rectangular specification per MIL-DTL-83513 (usually on 0.050” centers) provide many options including plastic housings, break-away, micro-threaded metal shells, twist-lock, and ACME ratcheting shells, and even space capability with outgassing per NASA SP-R-0022. Panel-mounted versions are designed for miniaturized electronics exposed to high shock and vibration as well as IP68 sealing.

Higher density can be provided by nano-circular connectors with contacts on 0.025” centers. Due to density, these are normally provided as factory terminated assemblies.

Ruggedized Nano 360® USB 3.0 by Omnetics with two micro contacts for power and six nano contacts for high-speed data, with overmolding for IP68 sealing.

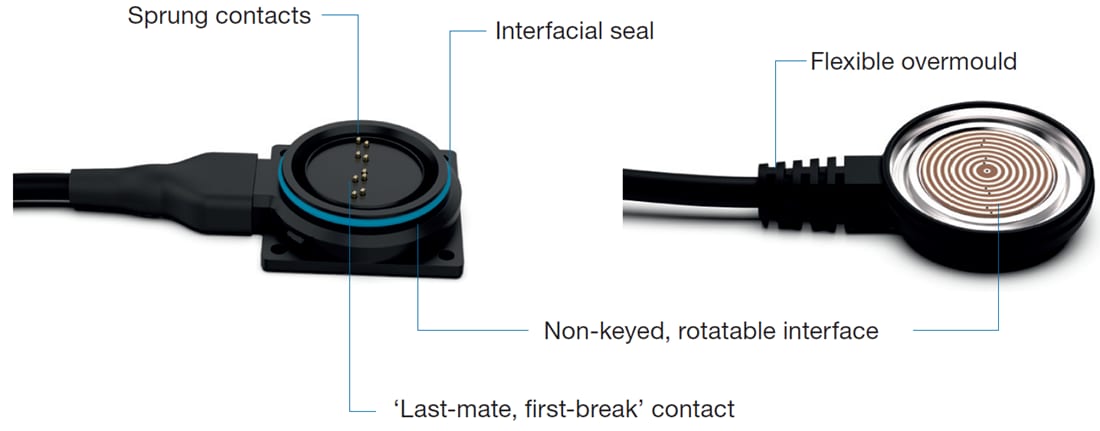

Many versions of micro and nano interconnects are suitable for UAVs, missiles, portable instruments, and satellites. However, applications, such as Nett Warrior, require quick mating/unmating, which limits use of polarized assemblies. In these cases, circular magnetic-latching connectors such as Amphenol’s Stingray are appropriate.

Modular assemblies provide customization

Many connectors permit interchangeability of insert sections to create an application-specific assembly. Insert combinations may reduce the number of connectors needed to lower total cost and reduce assembly.

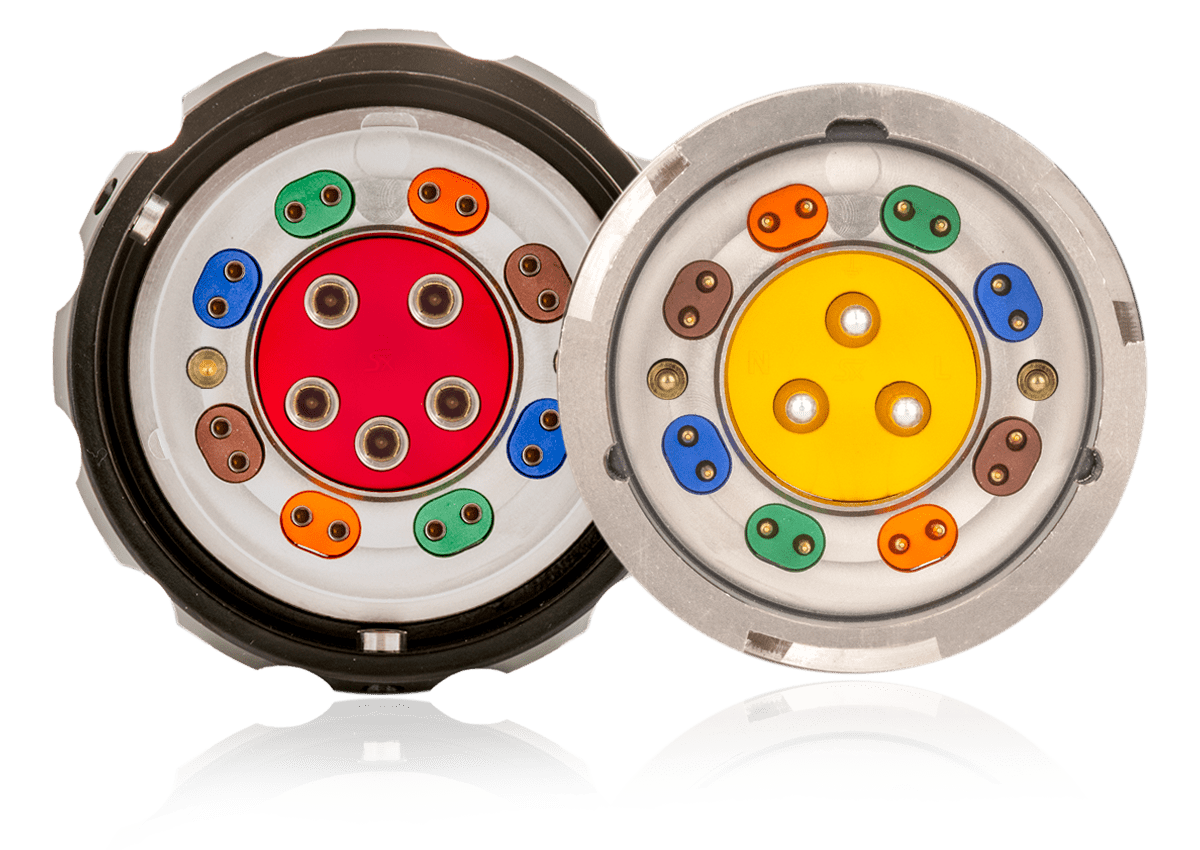

Shown below is as a unique commercial product line offering many assembly variations. These are Syntax SGH 8.1 inline connectors, by Valentini srl (Rivoli, Italy). The design permits one cable assembly to effectively manage (and keep separate) multiple wiring/modules for Ethernet, HDMI, and USB3+ with power or signals.

Color-coded sections are easily identified for assembly, test, and installation.

The metal core (at right, image 12) provides isolated channels and grounding between lines/cables. Conductive contacts carry ground between lines/cables. Conductive contacts carry ground between mating plug and receptacles.

Industry specifications

Many circular (and other) connectors are covered by U.S. Military, EIA, SAE, and other standards that define characteristics, testing methods, outline drawings, and QPL/QPD source listings. Sources for specifications include DLA ASSIST and the Standards Technology Group. Copies of EIA documents are available online at ECIA, and SAE documents are also available online.

References and coverage change over time and data references need to be kept up to date. For example, almost all basic MS31** drawings for circular connectors originally were established as a result of WWII under AN-W-C-591, which became MIL-C-5015 (later MIL-DTL-5015) that was superseded by SAE SAE-AS50151. QPLs/QPDs for most SAE-AS specifications are under the NAVAL Air Systems Command (NAVAIR) while the DLA maintains QPL/DPD data for most U.S. MIL-specs.

An extensive listing of most U.S., IEC, ESA/EN, and international specifications (including Chinese, Indian, etc.) and other standards for circular connectors (including MIL vs. EIA Test Procedures) are listed in Bishop’s recent report “World Circular Connector Market 2023.” Circular connectors have come a long way since James H. Cannon (Cannon Electric Company, now ITT Cannon) shipped his first Cannon “M” plug in 1923.

David Shaff’s World Circular Connector Market 2023 report, as well as other market research reports focused on the interconnect industry, are available through Bishop & Associates.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for AirBorn, Amphenol Industrial Operations, Amphenol Pcd, Amphenol LTW, ITT Cannon, Mouser Electronics, PEI-Genesis, and Omnetics Connector Corporation, Smiths Interconnect.

Like this article? Check out our other Circular Connectors and Standards articles, our Industrial Market Page, and our 2023 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- New Circular Connectors Add to Multi-Billion Dollar Market - January 9, 2024

- Counterfeit Components Ground Airlines - December 12, 2023

- Cables, Connectors, Waveguides, and Hybrid Products for up to THz at IMS 2023 - July 11, 2023