Renewable Integration: Tackling the Efficiency Challenges of Clean Energy and the Machine Learning Tech Needed to Get There

From electric vehicles to solar panels, energy innovation depends on efficient battery storage solutions. New opportunities to improve the efficiency of battery storage technologies devices is now possible with the dawn of AI, machine learning, and IoT.

The pressure is on to produce long-term clean energy alternatives to carbon-emitting gas and coal power for our vehicles, homes, and businesses. Cutting-edge clean capabilities are rapidly improving but several aspects of renewable energy technologies pose challenges to engineers. To compete successfully with nonrenewable options, clean energy technologies require a high degree of performance, which depends on efficient battery function.

Optimizing energy storage and prolonging the lifespan of cutting-edge batteries

Slowly but surely, many notable accomplishments and advancements have been made to clean energy technologies. For example, solar panels have been in use since the 1970s, but only recently has solar generation become the fastest-growing active source of megawatt power, powering homes, buildings, railways, aircraft, and other vehicles. The first and earliest versions of silicon photovoltaic solar cells were exorbitantly expensive to produce and battery tech was limited. Storage of energy created at the peak productive points of the day was inefficient, leading to energy shortages during non-peak hours at night or during days with cloud cover. The need to absorb energy at peak hours at high current speed while mitigating energy losses during storage has led to great strides in the field of battery technology. Recent advancements in liquid and solid-state lithium-ion batteries have proven superior to the previous go-to, lead-acid batteries. Their steeper upfront cost is now considered worthwhile over time due to higher energy density at a smaller size, lighter weight, and improved lifespan.

The switch to lithium-ion has proven fruitful, and electrification of the regulatory functions in the form of battery management systems is key to further exploration of the full capabilities of solar energy and other renewable options. Adjustments can be made within the regulatory functions of a battery management system and its accompanying PCB boards that can, in turn, improve overall functionality of a specific unit. The battery management system acts as a “brain” for the battery, prioritizing electrical loads and stopping and starting intakes and outgoing current. Regulating intake and discharge in a peak-production system preserves the long-term energy life of the battery and prevents the loss of high-speed current capabilities.

Some of the ways damage mitigation can be done include the accurate monitoring of the battery’s energy level. Connectors within the PCBs of the battery management system are integral to sending the signals necessary to communicate active battery levels in real-time. Consistent, accurate monitoring prevents the loss of signals, energy levels, and the battery’s own ability to store energy. Monitoring battery status via sensors can prevent batteries from draining too low and potentially causing internal damage. Also, active monitors on battery management systems can prevent the prolonged use of the maximum high-current rates, which cause small but steady loss of capability within the unit over time. This includes the use of high-intake or high-speed charging. Active communication within the management system enables the battery unit to regulate charging and use high-intake charging only at the optimal points of energy production. In the case of solar energy, for example, preserving high-current intake capabilities for only the peak points of daylight is one strategy to maximize efficiency. Alternatively, draining the battery quickly creates a rapid outgoing current, which can also lead to loss of capabilities over time, so preventing this opposite source of damage can also be managed within an optimized, wisely designed battery management system.

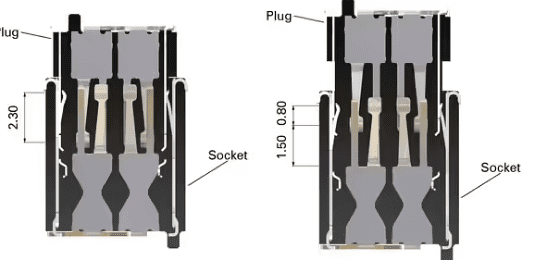

SMT interconnects are critical for battery regulation as they are both rugged and prevent the loss of electrical signal while the battery management system is functioning. To maximize a battery’s range and efficiency, a connector must maintain signal even in situations of movement and stress to the PCB. A connector with a double-contacting connection is an exceptional option to maximize a management system’s sensing capability for monitoring the battery’s status. Unlike conventional male and female connections, each offering either a blade contact or a spring contact, the double-contacting system is genderless (both blade and spring are present on each socket and plug). A double contact is made on each single pin, establishing maximum contact reliability for the signal.

Double contacting example, from an ept Zero8 0.8 mm SMT connector. The smooth, double-contact area ensures a fast and secure connection. Internally, the Zero8 connector also prevents contacts from being mated incorrectly during installation by submerging the contacts inside the insulating body, protecting contacts from damage.

The more recharging and drainage cycles that a battery performs, the more it will degrade over time. However, a well-designed battery management system can mitigate damage and prolong functional life.

Optimizing the creation of energy with machine learning

New technology in batteries themselves, as well as in their accompanying management systems, has created massive opportunity for advancements in clean energy. However, additional opportunity to hone in on the efficiency of devices is now possible with the dawn of AI, machine learning, and IoT.

IoT, or the Internet of Things, involves massive amounts of data from millions of electronic devices. Artificial intelligence, or AI, attempts to mimic human intelligence and creativity to perform given tasks. A subset of the wider umbrella of AI, machine learning focuses on the analysis of available IoT data and uses AI capabilities to interpret it. Machine learning uses data and makes the best possible decision without direct human intervention or instruction.

Machine learning has the potential to process massive amounts of incoming data and make split-second decisions within a system, without the need for human intervention. This can be used to help make solar, wind, hydropower, and tidal shift energy feasible on a large-scale. For example, AI can process new IoT information about incoming weather and subsequently adjust hydropower or tidal energy-gathering technology to take advantage of increasing water speeds or higher tides. Machine-learning systems can also be used to recognize anomalies, for example, if a source of outside interference comes into play, choices can be made without a human present to make system adjustments. In cases of inclement weather or other randomized extreme conditions, machine learning can make the choice to temporarily halt attempts at energy production to save critical hardware from overload and prevent costly system failures.

Negotiating the difficulties of outside interferences requires a system to recognize the problem and react to it in a timely manner. High-speed connectors are necessary for high-speed decision making; the faster a machine-learning system can internally communicate, the faster it can adapt. 25 Gbit+ has been present in the IoT space for several years and has become a standard for data centers. Still, this isn’t as far as technology could go. Even the demands of PCIe 5.0 are now double that of its predecessor PCIe 4.0, with a maximum data transfer rate of 32 GT/s (gigabit transfers per second). Choosing a reliable, high speed connector is the optimal choice to keep information coming from the IoT space processed and interpreted at max speed in a green energy solution.

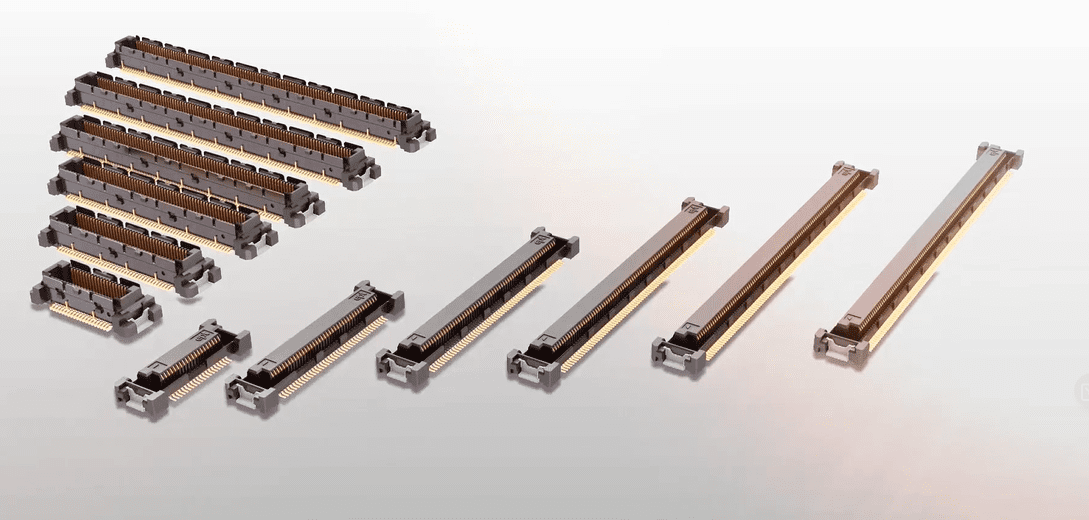

Miniaturization continues to be prioritized in many industries and ept’s high-speed Colibri Connector System is perfect for data stations, data storage and other abilities necessary for IoT, IIoT, and machine learning, and for grids and micro-grid energy storage.

Connectors have proven critical in successful cutting-edge battery management systems, as well as AI machine learning optimization. There are still steps to be made in the clean energy space, and high-performance PCB design makes the advanced electrification necessities (lightning-fast machine learning reactions, optimal battery tech) viable enough to compete with outdated gas and coal.

To learn more about solutions for clean energy technologies, visit ept USA.

Like this article? Check out our other Artificial Intelligence and IoT articles, our Industrial Market Page, and our 2023 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.