Micro-Ds Keep High-Tech Drilling Tools Connected

Few harsh environments are as harsh as oil & gas wells. Connectors and cable assemblies must be tough enough to maintain reliable connections despite extreme high temperatures, severe shock and vibration, fluid corrosion, and more.

Micro-Ds and other rugged interconnects play a huge role in today’s oil & gas industry. Since 1859, when Edwin Drake constructed the first official drilling rig, oil drilling and the accompanying technology have been steadily advancing. Drake used a steam engine and a cable-tool drilling rig to drill down 69.5 feet, creating what has been called the first commercial well. The progress was slow, breaking through the rock a couple of feet a day. In comparison, today’s wells can range from a few hundred feet to over 20,000 feet in depth. Per day, drilling operations can cost hundreds of thousands of dollars and drill thousands of feet.

Technology shifted from steam engines to combustion engines, from mechanical power to electric power. By the 1970s, onsite generators were in use and mud-pulse technology allowed drill operators to locate drill bits underground. The 1980s brought steerable drilling. In this century, autonomous rigs that walk on hydraulic legs enable one rig to drill multiple wells without the need for tear-down and set-up.

As the equipment and machinery progress, so do the connectivity solutions. “Oil & gas is one of those industries where all the equipment is subjected to very harsh environment conditions: high temperatures and pressure, shock and vibration, fluid corrosion, you name it,” said Raphael Bauron, account manager at Axon’ Cable. As a result, the connectors, cables, and cable harnesses must be able to withstand the most severe conditions while maintaining a secure and reliable connection.

Bauron explained that customers in this market use connectors, cables, and harnesses in sophisticated high-tech tools that go down in the well — tools for prospecting, drilling, explosives, measuring while drilling (MWD) and logging while drilling (LWD).

MWD is a way of measuring temperature, pressure, and wellbore trajectory (direction in which the well is drilled) downhole. Data is sent to the surface continuously, in real time. LWD is a process of recording, storing, and transmitting formation evaluation data about the area around the borehole. These operations use sophisticated technology such as gamma sensors to detect gamma radiation from rock formations, X-ray imaging, geolocators, and magnetometers.

The tools are filled with electronics for steering and moving them, and for collecting and transmitting mass amounts of data. Depending on the nature of the signal, operators can tell if the tool found rock, mud, or oil.

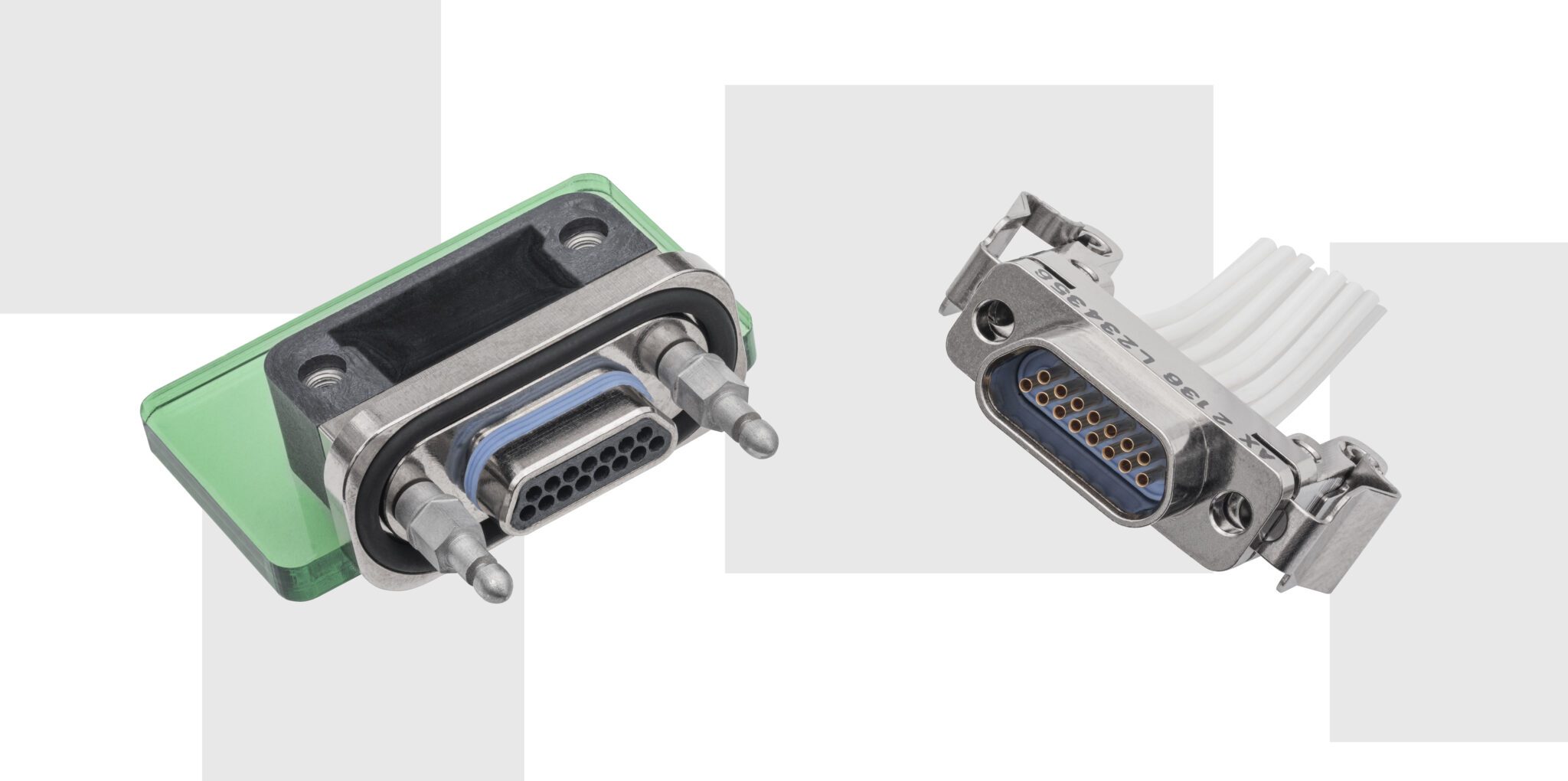

The main requirement for connectors in this application is strength. “Our micro-D connectors were developed initially for military applications,” Bauron said. “They are machined out of a big block of aluminum, so they’re very strong. They’re nickel plated for protection against corrosion with a liquid crystal polymer (LCP) insert. Micro Ds can withstand up to 260 °C for the highest temperature connections. All this encapsulated in high temperature epoxy makes a very robust connector.” Overmolding protects the connectors and connections in harsh environments and helps with strain relief.

Despite their small size, micro-D connectors are highly resistant to shocks and vibrations. Axon’ Cable offers a complete range of rectangular micro-D connectors based on MIL-DTL-83513: PCB, pigtails, savers, strips, solder cups, and complex multi-branched harnesses. For the most demanding oil & gas applications, filtered, non-magnetic, hermetic, and circular connectors are available.

High density is another important factor. “More and more technology is being packed into these tools. The wells aren’t getting bigger and the tools aren’t getting bigger. So, everything inside has to get smaller,” said Bauron. “We used to make 9- to 15-position connectors, now we’re using 21-, 25-, 37-position connectors, because there are a lot more wires, a lot more connections, a lot more data. And all this still in the same space.”

Wires with PTFE insulation are very strong, resistant to very high temperatures, and resistant to abrasion. Cable harnesses bring power from the battery to the accelerometer to the magnetometers and other electronic equipment. “Axon’ makes a harness that is multi-branched to connect all the equipment inside. It looks like a big octopus,” said Bauron.

Axon’ Cable “octopus” cable harness

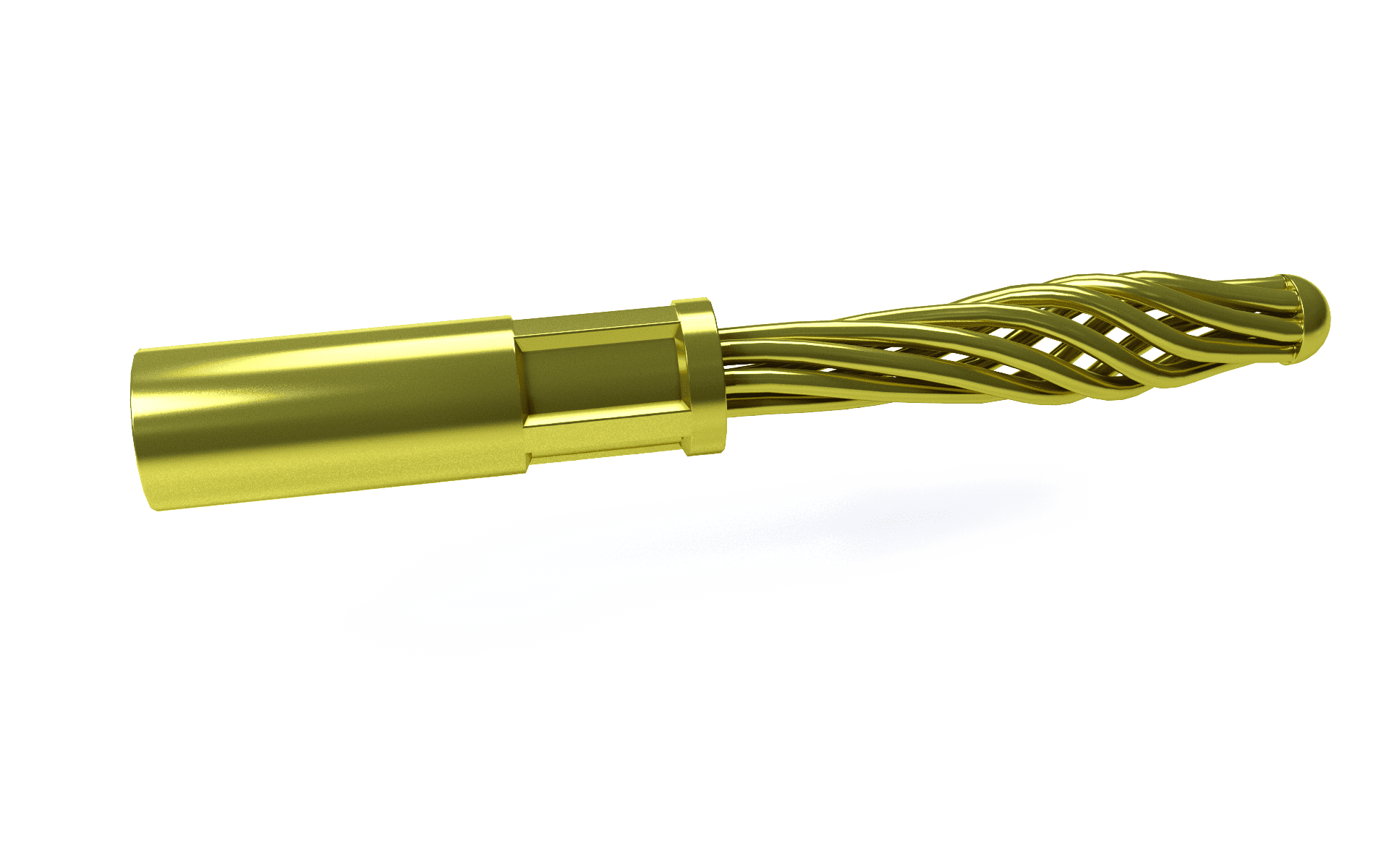

Drilling through rocks makes everything shake, and the equipment must stay connected throughout the drilling process. Axon’, as well as some of its competitors, uses gold plated pins called twist pins. They are encased in a birdcage-like wire structure that acts as a spring. Seven strands compress slightly to form a tight connection. The male and female are always in contact, so there is no loss of signal during drilling. Each of the connectors on that cable harness is mounted on the board. There are PCBs throughout the tool and each board has a connector to interface. The cable harness takes the signal wherever it needs to go.

Axon Cable twist pin

Some applications have tight spaces that are too small for even the popular micro-D connector. The nano-D is half the pitch (25/1000 of an inch). Its tiny size makes it ideal for use in the smallest tools when space is exceptionally limited. Because it is so small, however, it is too delicate to completely replace the micro-D. Waterproof and hermetic connectors are useful in the oil & gas market, as well as anywhere fluids, dirt, and debris can impact performance.

Another way to reduce the amount of space needed for these connections is by combining different functions into one connector. Combo micro-D connectors provides power and RF signal, eliminating the need for multiple lines.

Visit the Preferred Supplier page for Axon’ Cable to learn more about the company and its products.

Like this article? Check out our other high-reliability and harsh environment articles, our Industrial Market Page, and our 2023 and 2022 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024