Maximize UL Voltage Ratings in Power and Control Systems for Mobile Equipment

Rail and other connected mobile systems depend on control devices that meet specific UL guidelines. Coordinating components can maximize actual achievable voltage levels.

Power and control devices for mobility applications are designed with specific application voltage ratings in mind. The components used to electrically connect these devices to mobile equipment, from elevators to rail systems, also have to match these ratings. In addition, for devices like power supplies to be UL-certified for a given voltage rating, say 1,000V operation, all of their enabling components must also be UL-certified for that 1,000 V rating. If all of the components in a device are UL-certified to the required voltage level, then no further examination is required to assign that voltage level to the device. In practice, however, the UL-rated voltage of power and control devices is often restricted by one or more of its components.

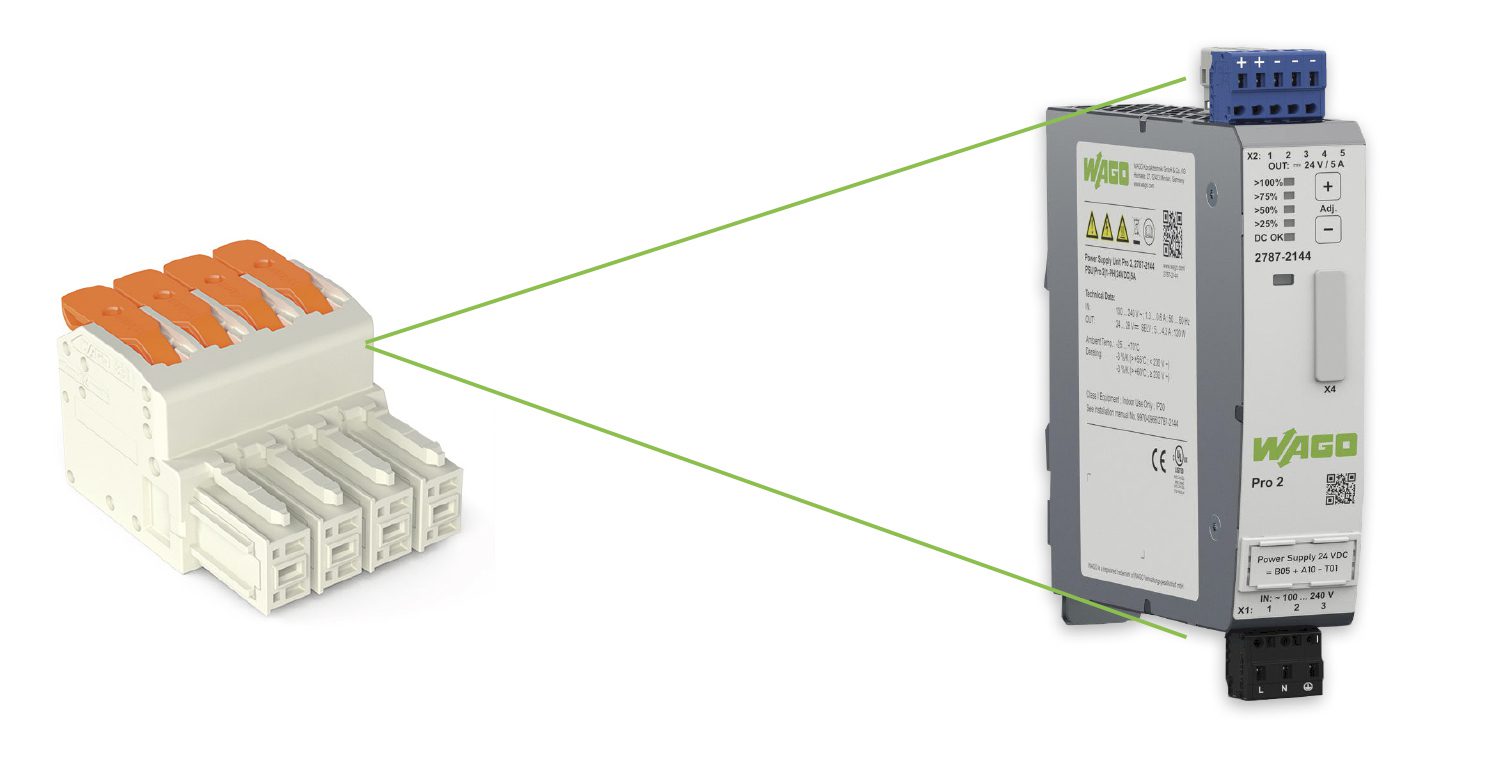

Enabling components, like the connector on the left, must match the UL-rated voltage for the devices they’re designed into, like the power supply on the right.

Components such as PCB terminal blocks and pluggable connectors are typically certified according to UL 1059 and CSA-C22.2 No. 158 in North America and parts of Asia. In Europe, these components are evaluated according to EN 61984, which mandates that rated voltage is determined according to requirements for clearance and creepage distances per EN60664-1. The UL 1059 standard also has requirements for clearance and creepage distances, but they are much greater than EN 60664-1 requirements. Therefore, rated voltage according to UL 1059 will always be lower than ratings achievable according to EN 60664-1, even for identical interconnect components.

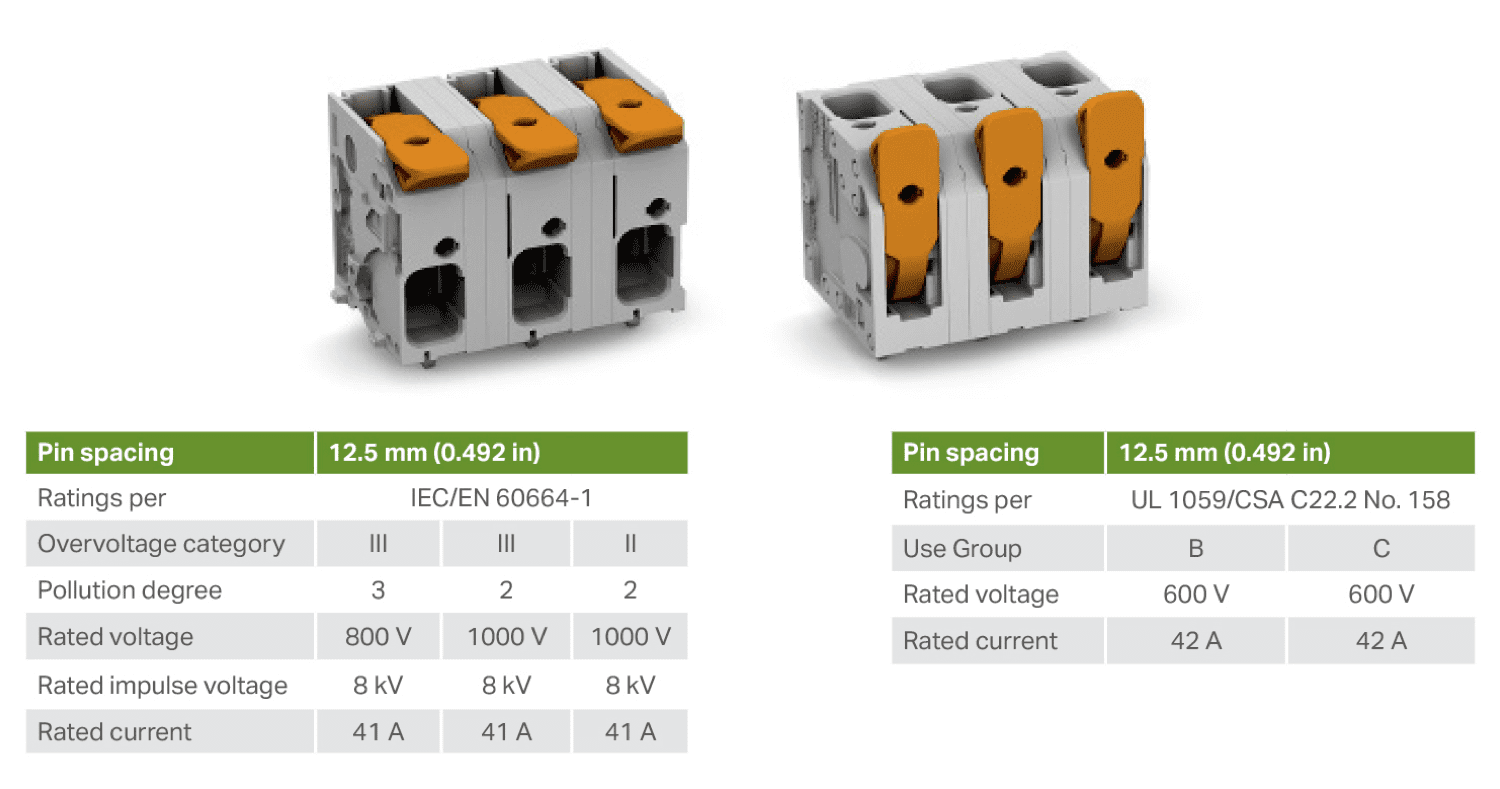

WAGO’s 2606 Series PCB terminal blocks with push-in CAGE CLAMP and lever mechanisms are compact, carry high currents, and enable quick, easy, and secure connections. The identical 12.5mm-pitch 2606 Series PCB terminal blocks pictured here are rated for 800–1,000V operation per IEC/EN but only 600V UL/CSA because the two sets of standards have different clearance and creepage distance requirements.

Sometimes, the relatively narrow scope of a component standard, like the UL 1059 terminal block standard, becomes an obstacle to overcome in order to attain the desired voltage rating for a power supply, control device, or panel intended for use in mobility applications.

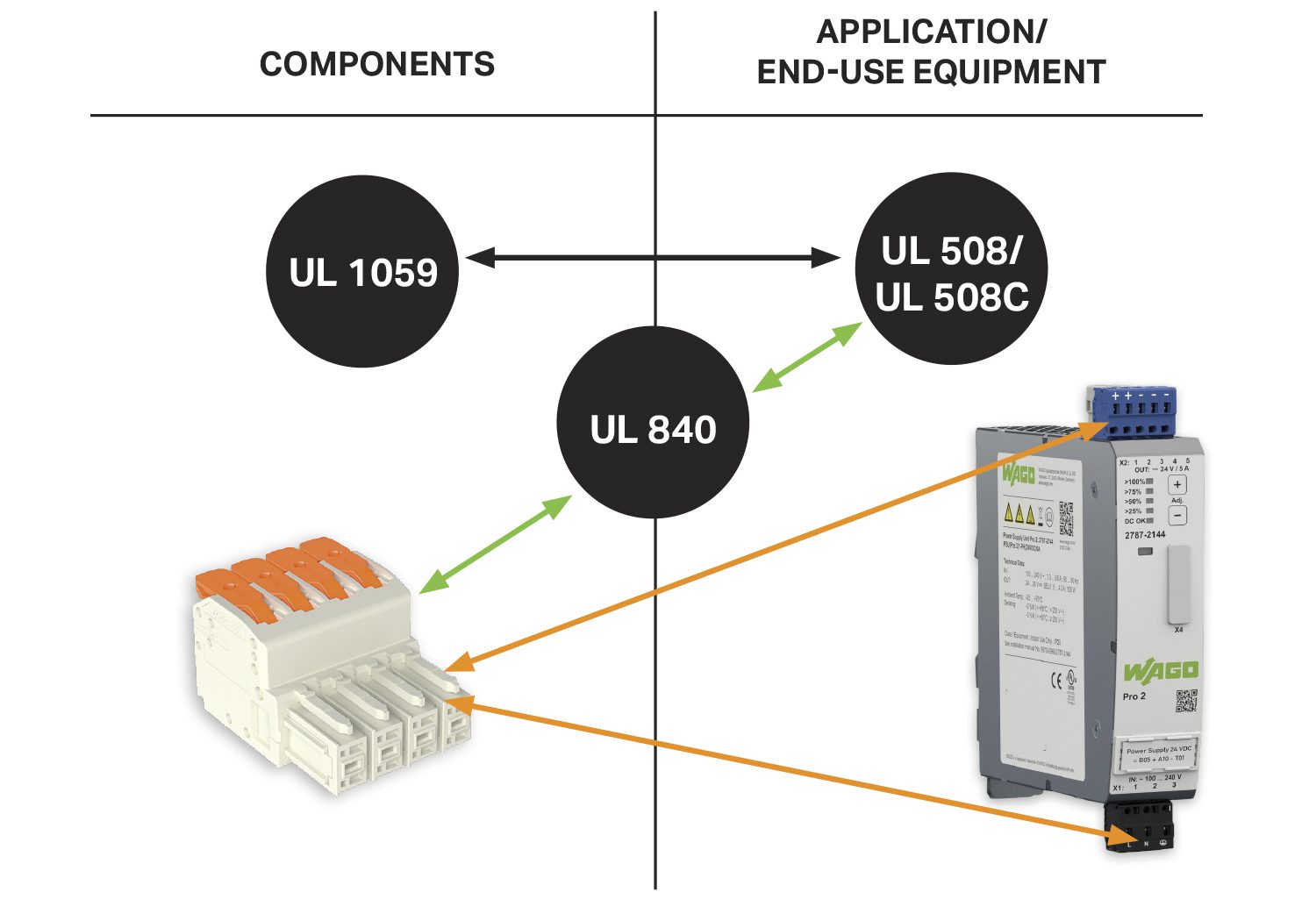

For example, the UL 508 Industrial Control Equipment and UL 508C Power Conversion Equipment standards serve as the primary reference points for most control panels and power devices used in mobility applications from elevator and escalator control panels to rail controls. When a component is designed into an end device subject to these standards, it also becomes subject to these standards, but both UL 508 and UL 508C first refer to UL 1059 and other applicable component standards to determine the rated voltage for the end device. Acceptance for approval without further examination requires that the specified component is certified accordingly and at the required voltage, which is often not the case.

However, even in these instances, the employment of the problematic component is not necessarily precluded. One possible solution is to adjust the component construction to meet the clearance and creepage requirements for UL 1059 compliance at higher voltages, which can be relatively easy when using modular components like PCB terminal blocks. For example, WAGO PCB terminal blocks equipped with spacers can meet UL 1059 clearance and creepage requirements for 1,000V applications.

The WAGO 2606-13xx PCB terminal block pictured here features additional spacers to achieve the clearance and creepage distances mandated in the UL 1059 standard for a UL-rated voltage of 1,000V.

In instances where the added dimensions of such alternate constructions are prohibitive based on available space, the UL508 and UL508C standards also allow end-use equipment manufacturers to examine the clearance and creepage distances for interconnect components according to the UL 840 Standard for Insulation Coordination Including Clearances and Creepage Distances for Electrical Equipment. The UL 840 standard “cover[s] an alternate approach to specifying through-air and over-surface spacing for electrical equipment through the use of the principles of insulation coordination” and was essentially developed as an alternative that better aligns with the requirements of IEC/EN 60664-1. It is, however, important to note that, when evaluating alternative clearance and creepage distances according to UL 840, manufacturers must consider both overvoltage category and pollution degree in order to determine the rated voltage, just as they would for compliance with EN 60664-1.

The clearance and creepage distance requirements for the UL 840 and EN 60664-1 standards are nearly identical and are considerably lower than those mandated by the UL 1059 standard, enabling higher UL-rated voltages for end devices than components solely evaluated for compliance with the UL 1059 standard.

In addition, since the UL 508 or UL 508C standards serve as the basis for, or — at the very least — are referenced within, the standards for other electrical equipment, the aforementioned solutions may still indirectly apply even in instances where an end device doesn’t fall directly within the scope of the UL 508 or UL 508C standards.

When that is not the case, which is often true for factory-wired connections, the UL 1977 safety standard for component connectors employed in data, signal, control, and power circuits offers yet another potential method for end-use equipment certification, provided that it is referenced in the end-use equipment specification. The clearance and creepage distance requirements for the UL 1977 standard are also considerably lower than those defined in the UL 1059 standard, which can allow manufacturers to achieve higher UL-rated voltages. For other factory-wiring applications, manufacturers may consider interconnect components approved to both UL 1977 and UL 1059.

In addition, it is critical to note that the UL 1977 certification shall not be used as the voltage ratings basis for field-wiring applications. Also worth noting is that both UL 1059 and UL 1977 are component approvals, which means that component manufacturers are responsible for compliance, whereas UL 508 and UL 508C are end-use equipment approvals, which means that OEMs are responsible for compliance.

For more information, visit WAGO online.