EVs Herald a Shift in Powertrain Connectivity

Innovation in electric vehicle technologies — including the integration of new rugged board-to-board connectors — have expanded mileage ranges and decreased charging time.

Despite the negative impacts of supply chain issues and the COVID pandemic on the automotive market, EV registrations are rapidly increasing in major global markets. Most car manufacturers have made significant investments in hybrid electric vehicles (HEVs) and EVs, and the next few years will bring more options to consumers in every vehicle category. New technologies have increased mileage ranges and decreased charging time. These powertrain advancements depend on higher-voltage connectors that use less real estate, while meeting the requirements of heat and vibration resistance. New rugged board-to-board connectors can help increase performance, while reducing design and assembly costs. High-voltage connectors that feature a floating contact system not only simplify assembly, but also offer enhanced vibration resistance, an important consideration in HEV and EV applications.

With an expanding charging infrastructure and more than 16 million electric vehicles on the road in 2021, the attractiveness of HEVs and EVs is rapidly growing. This can be attributed to consumer demand for eco-friendly vehicles combined with increased confidence in the technology. Because HEVs use less gasoline and EVs use no gasoline, these vehicles are much quieter, cleaner during operation, less costly to refuel, and typically require less maintenance due to fewer moving parts and subsequent wear and tear. Growth Market Reports states that the electric vehicle market was valued at USD 273.31 billion in 2020 and is projected to reach USD 802.75 billion by 2028, expanding at a CAGR of 21.6% during the forecast period.

Factors for increased HEV and EV sales include favorable government policies and support in terms of subsidies and grants, tax rebates, and other non-financial benefits. Proactive participation by automotive OEMs is also starting to drive the global electric vehicle sales.

Almost every automotive manufacturer has HEV or EV vehicles in its future production schedule, and many of these models are coming onto the market right now. Consumers are realizing that the latest electric vehicles offer many advantages over traditional internal combustion engines (ICE), including lower maintenance costs and the convenience and independence of charging at home, especially during periods of high gas prices.

Powertrain basics

The powertrain of an EV is a simpler and more efficient system compared to ICE systems. EVs can run solely on electric propulsion or they can work alongside ICE systems in HEVs. An EV system has fewer parts by up to 60%, and even fewer moving parts. At its core, a standard EV system contains a charger, battery pack, converter, controller, and motor.

- The charger converts power received through the charge port from AC to DC and controls the amount of current flowing into the battery pack.

- The battery pack is made up of multiple Lithium-ion cells and stores the energy needed to run the vehicle. Battery packs provide DC output.

- The inverter transfers DC power from the battery pack to AC to power the electric motor.

- The electric vehicle controller is the electronics package that operates between the batteries and the motor to control the electric vehicle’s speed and acceleration, much like a carburetor does in a gasoline-powered vehicle.

- The electric motor converts electrical energy to mechanical energy to move the vehicle via a simple single or dual speed transmission to reduce wheel speed and multiply torque.

Powertrain connector requirements

In all automotive applications, connectors must offer high reliability performance in terms of resistance to heat, shock, vibration, and other environmental conditions. In addition, powertrain systems require rugged and reliable interconnect solutions that can handle higher currents. For example, an EV motor can run anywhere from 96 to 800 Volts DC. HEVs typically feature nominal pack voltages ranging from 96 V to 200 V, while EVs must support 400 V to 800 V and higher. A three-phase AC motor is most likely operating at 240 V with a 300 V battery pack.

One downside of higher voltages is the demand for higher-voltage-rated connectors.

Powertrain connector trend: A shift to floating board-to-board

Previously, wire-to-board connectors were commonly used in HEV and EV drivetrain applications. This includes connectivity for motor controllers, inverters, and more. However, wire-to-board connectors take up more real estate and can often be more taxing during the integration and assembly process. New board-to-board connectors that feature a floating contact system simplify assembly and reduce labor costs, all while offering space savings.

These versatile board-to-board connectors combine high voltage ratings up to 125 V AC/DC in a small footprint with a 1 mm pitch. Offering high temperature resistance up to 140 °C, new connector designs with a floating contact design provide superior vibration resistance for more reliable operation.

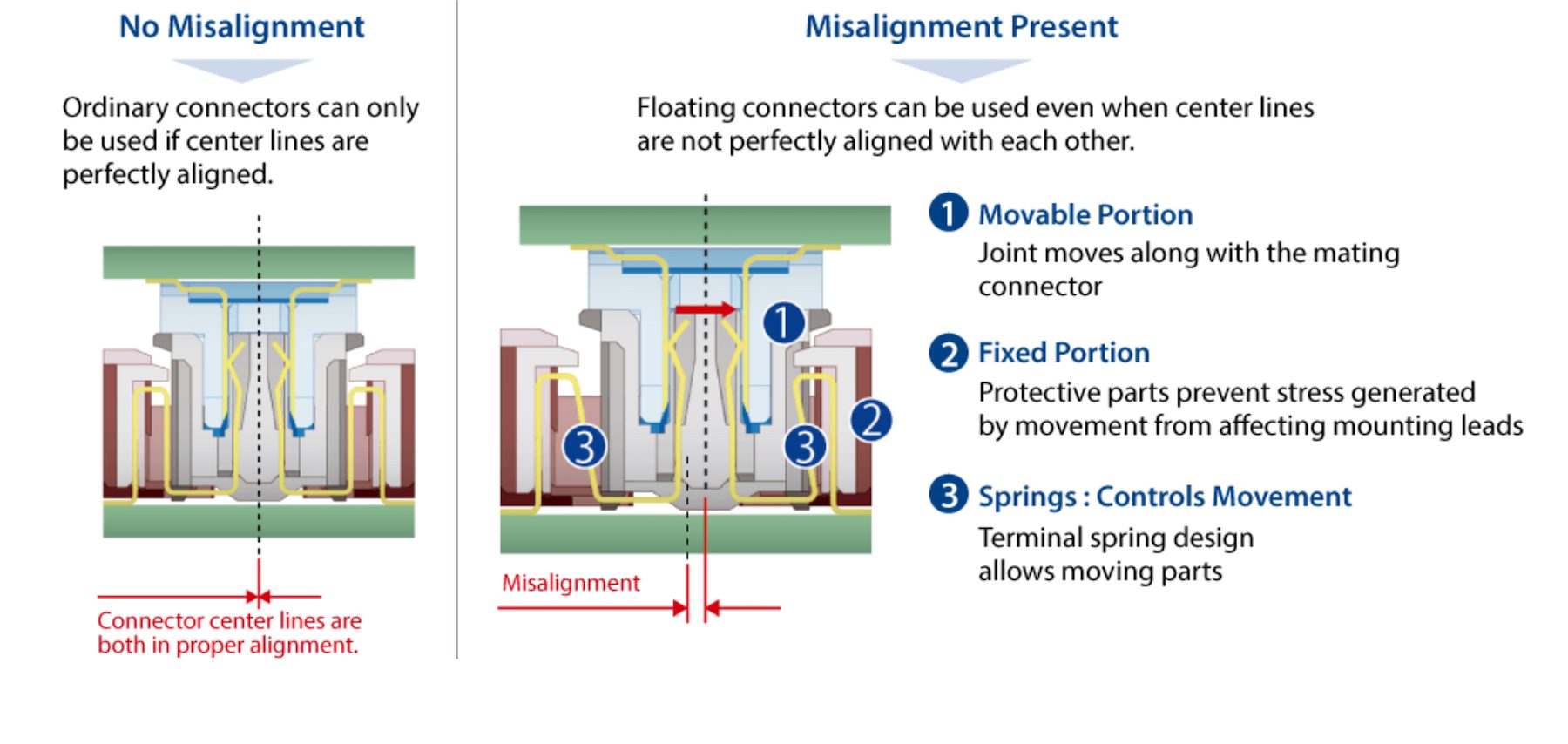

Floating contacts can compensate for alignment errors up to ± 0.7 mm in both the X- and Y-axis directions, as well as ± 0.75 mm tolerance between the boards in the Z direction. This floating feature absorbs misalignment during board installation and mounting. Because the spring portion of the terminal absorbs assembly errors, it reduces the need for corrective re-work operations. The floating contact system is ideal for HEV and EV drivetrain systems that require multiple connectors to be used on the same board.

In addition, the floating contact system, like the one found in Hirose’s FX26 Series board-to-board connector, increases reliability by reducing the stress on solder joints caused by misaligned connectors. The floating design also enhances durability by preventing solder cracking.

HEVs and EVs are already offering longer ranges, more horsepower, lower emissions, less maintenance, and lower long-term costs, and car buyers are responding. Connector manufacturers continue to develop innovative interconnect solutions to support advancements in EV powertrains. These connectors offer reliable and durable operation with enhanced functionality and features — all in small and lightweight packages. HEV and EV connector solutions simplify design, ease assembly, and improve end-product performance.

Visit Hirose Electric to learn more about innovative connectivity solutions for next-generation vehicles.

Like this article? Check out our other articles on EVs and HEVs, technology trends, our Automotive Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- EVs Herald a Shift in Powertrain Connectivity - August 30, 2022