Common Misperceptions of Custom Connectors

There are many misperceptions regarding custom connectors: They are too risky, too expensive, and take too long to develop. But new processes are addressing these concerns.

Device development is undergoing a transformation. Pressure to reduce costs, reduce size, and make devices that can leverage the Internet of Things (IoT) and 5G is driving a lot of new design activity. The original equipment manufacturers (OEMs) creating new products are dealing with opposing challenges when designing for connectivity. Striking the right balance between meeting new trends and the classic needs of the market pose problems and require device manufacturers to think differently. Standard connectors are not always the best choice, but custom connectors strike fear in many OEMs.

There are many misperceptions regarding custom connectors. The three most common are that they are too risky, take too long to develop, and are too expensive. But new development strategies and new production trends are addressing these concerns.

Misperception: It’s too risky to ensure quality in a custom connector.

Going with a new contact design could create unknown problems. However, custom doesn’t always mean a totally new contact system Connector suppliers with a reputation for high-quality products, a broad product portfolio, and experience in customization can significantly reduce the risks associated with developing an entirely new connector by utilizing existing connector components, basing a custom connector on an existing contact system, and having a defined development process for customized solutions. Repurposing connector components into a customer-specific solution can meet application demands with much less risk than is associated with ground-up development.

Phoenix Contact offers an extensive portfolio of standard industrial connectors and housings and is well versed in leveraging its core technology to develop custom-engineered solutions with significantly reduced risk.

Misperception: Custom connectors take too long to develop.

Off-the-shelf connectors can be quick to design-in, but if they have to be made more robust for use in industrial applications, the design process could require additional time for testing and validation and potentially create additional production costs as well. In comparison, the strategy of utilizing existing connector components and repurposing them to develop a new industrial connector can significantly reduce both validation time and the costs associated with new agency approvals.

Tooling lead-times must be considered as well, even though new technologies like additive manufacturing can greatly reduce them. Printed metals are coming closer to the performance of machined or stamped and formed contacts, and plastic materials are beginning to approach the high-temperature and flame-retardancy requirements needed for industrial agency approvals. But it’s not just connector components that can benefit from additive manufacturing; the tooling used to make those components benefits as well. Printing injection molds and inserts can greatly reduce the lead-time for injection molded components, making it possible to get a concept and custom connector solution up and running quickly. As such, connector manufacturers with in-house additive manufacturing capabilities are rapidly changing the way many OEMs consider custom connector solutions.

3-D printing is one additive manufacturing technology that is changing the way OEMs view custom connector solutions.

Strong relationships between developers and manufacturing partners are critical to bringing products to market faster in this global economy. OEMs need to have good communication skills and work effectively with partners who can handle global projects.

Partnering with connector suppliers with proven experience in customized solutions can be beneficial in multiple ways, including reduced development timelines. Development processes for standard products are much different than those for custom products. OEMs can’t wait for a process that gathers market needs and then revises and validates a concept through customer feedback. Such a process could take months or years to finalize a concept, and a custom connector development should take weeks, not months. OEMs must find a connector supplier that understands this, can adjust the development process during concept stages to meet critical timelines, and can provide budgetary proposals quickly and with a high degree of accuracy.

Misperception: Custom connectors are too expensive.

When looking at the unit cost of commercial connectors, a customized solution might be higher. However, design concessions must be considered as well. High-density, office-grade connectors can’t withstand the temperatures, shock, and vibration or deliver the plating thicknesses and, in many cases, the ingress protection needed for many applications. Design concessions are needed to account for these differences, since they all add production costs and, as such, make customized solutions even more attractive in comparison. Plus, when a connector supplier also has experience developing housings for electronics, a customized solution can integrate the connection technology into the housing, ensuring the most efficient use of space and reducing overall assembly costs.

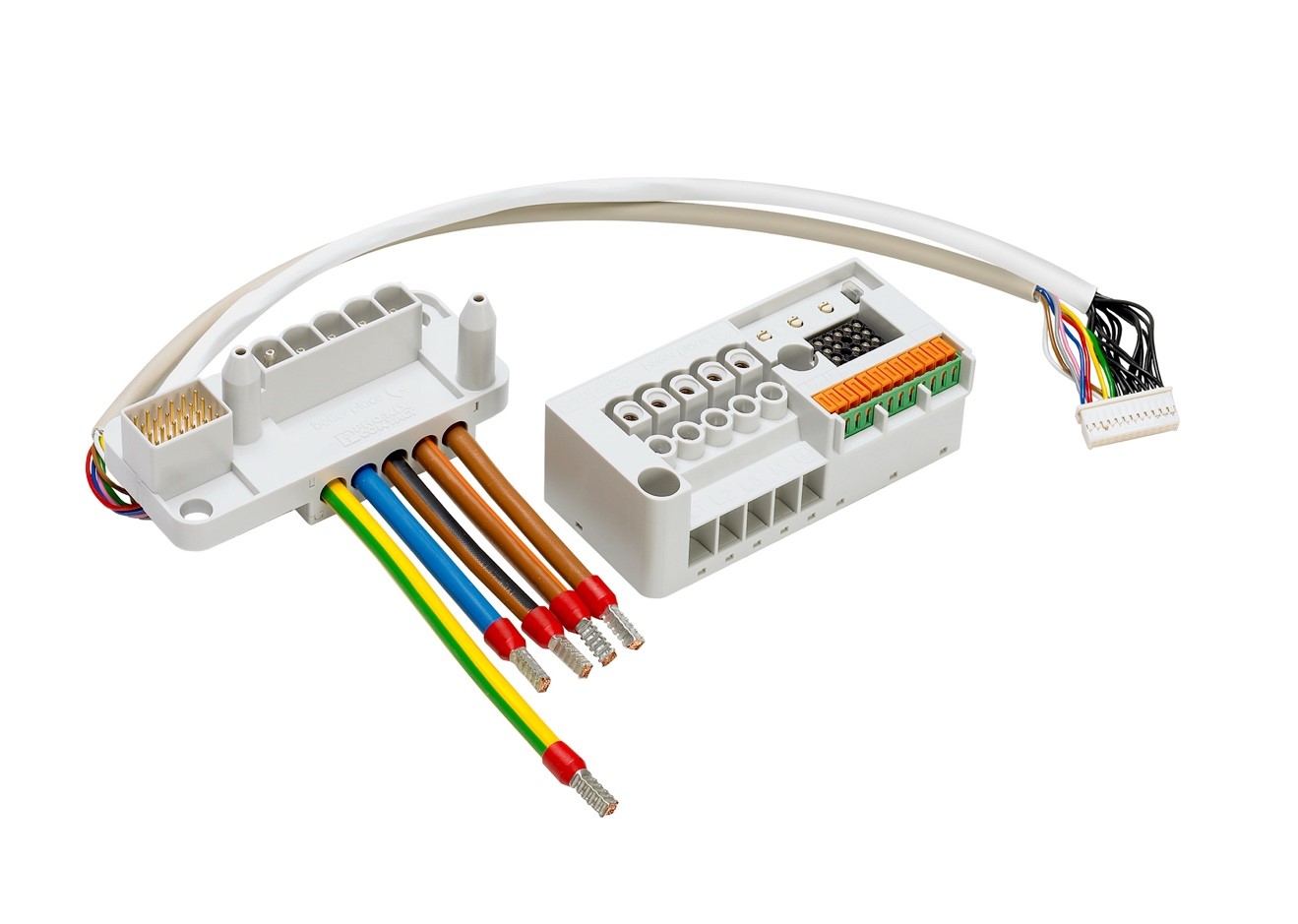

Integrating hybrid connectors into electronic housings can significantly reduce production costs.

Conclusion

OEMs are under great pressure to quickly develop new products that increase intelligence and functionality, reduce size and weight, and provide attractive price/performance benefits — and all without sacrificing robustness. Expanding I/O counts and networking capabilities can accomplish this, but the pressure to reduce size is in direct opposition to this solution.

When considering all the challenges to making standard, off-the-shelf solutions work, customized solutions become much more attractive. If one connector met everyone’s needs, there wouldn’t be thousands of different types of connectors available today. Customized solutions can meet high-density needs by combining networking, power, and I/O into a hybrid connector that can be integrated into the product housing to save production costs. They can also provide the individual look and feel required to strengthen an OEM’s brand.

Once an OEM decides that a custom connector solution is the right choice, the next step is choosing the right connector company to partner with. A connector supplier that is well recognized for quality, has global capabilities, and is experienced in developing custom solutions is critical for success. A valuable partner should also offer design consultation, not just subcontracting services. A deep understanding of plastics, contact design, and — most importantly — how they come together to make a quality connector is needed as well. Balancing the technical and commercial requirements will provide the best solution possible.

Visit Phoenix Contact USA online.

Like this article? Check out our other Connector Basics, manufacturing, and 2019 articles and our Industrial Market Page.

- New Technologies Force Heavy Equipment OEMs to Rethink Connector Solutions - November 17, 2020

- Common Misperceptions of Custom Connectors - October 1, 2019