Problem Solved – Kelvin Technologies Error-Proofs the Process with Schleuniger Machines

Problem Solved – Kelvin Technologies Error-Proofs the Process with Schleuniger Machines

Kelvin Technologies has more than 100 years of combined experience in electrical heating, controlling, and sensing. Located in Mississauga, Ontario, Canada, the company specializes in electrical heaters, microprocessor controls, temperature sensors, custom-built harnesses, and custom designs. Kelvin Technologies has a product to fit each of its customer’s needs.

Kelvin Technologies’ employees were using hand tools to manually cut, strip, and hand-crimp a specialized thermocouple cable. To increase their productivity and efficiency, Kelvin asked Schleuniger Inc. to review the overall process and suggest possible products to speed up and simplify the process. Schleuniger recommended three cable processing machines to increase productivity: the EcoStrip 9300 Automatic Cut and Strip Machine; the UniStrip 2600 Wire Stripping Machine; and the UniCrimp 200 Crimping Machine.

The EcoStrip 9300 is an efficient, automatic wire and cable cut-and-strip machine. Wide application range, high productivity, simple operation, and high stripping quality are its main advantages. The all-electric EcoStrip 9300 processes round cables and wires up to 6mm (0.235”) outer diameter and flat ribbon cables up to a width of 13mm (0.511”) with a stripping length up to 999.9mm (3.28 ft.). Kelvin would benefit from quick programming, simple operation (due to the LED programming guide and display), a quick-change guide, integrated wire jam detector and out-of-wire sensor, and special cable processing capabilities.

The EcoStrip 9300 is an efficient, automatic wire and cable cut-and-strip machine. Wide application range, high productivity, simple operation, and high stripping quality are its main advantages. The all-electric EcoStrip 9300 processes round cables and wires up to 6mm (0.235”) outer diameter and flat ribbon cables up to a width of 13mm (0.511”) with a stripping length up to 999.9mm (3.28 ft.). Kelvin would benefit from quick programming, simple operation (due to the LED programming guide and display), a quick-change guide, integrated wire jam detector and out-of-wire sensor, and special cable processing capabilities.

The UniStrip 2600 is one of the most flexible stripping machines on the market, with the ability to process discrete wires from 0.03 to 16mm² (32 to 6 AWG), round cables up to 9mm (0.35”) in diameter, and flat cables up to 11mm (0.43”) wide. Stripping lengths up to 80mm (3.14”) are possible, with a maximum pull-off length of 40mm (1.57”). It has a virtually unlimited range of applications, is fully programmable with up to 1,000 memory locations, and is fully  electric, featuring strong, quiet drives and fast cycle times. The benefits of the UniStrip 2600 include high precision and user friendliness. Precision mechanics coupled with new-generation electronics guarantee repeatable stripping quality; the stripping head accepts different blade types; blades can be changed quickly and easily without any tools. Programming the machine is quick, thanks to menu-guided data entry and a graphical display of the programmed wire end, and a library of standard wire sizes (in mm² and AWG) makes it easy to program new wires using default parameters for the selected wire size. As an alternative, wires can also be programmed and managed offline on a PC using Iguana wire processing software. Equipped with the optional SmartStrip function, the UniStrip 2600 virtually eliminates operator mistakes. Loading different programs between jobs becomes obsolete. With SmartStrip, the wire diameter is automatically detected and wires are processed according to preprogrammed parameters. Easy insertion of the wire, cycle start by means of an automatic sensor, and the ability to clearly view the entire operation through the safety shield further add to the user-friendliness.

electric, featuring strong, quiet drives and fast cycle times. The benefits of the UniStrip 2600 include high precision and user friendliness. Precision mechanics coupled with new-generation electronics guarantee repeatable stripping quality; the stripping head accepts different blade types; blades can be changed quickly and easily without any tools. Programming the machine is quick, thanks to menu-guided data entry and a graphical display of the programmed wire end, and a library of standard wire sizes (in mm² and AWG) makes it easy to program new wires using default parameters for the selected wire size. As an alternative, wires can also be programmed and managed offline on a PC using Iguana wire processing software. Equipped with the optional SmartStrip function, the UniStrip 2600 virtually eliminates operator mistakes. Loading different programs between jobs becomes obsolete. With SmartStrip, the wire diameter is automatically detected and wires are processed according to preprogrammed parameters. Easy insertion of the wire, cycle start by means of an automatic sensor, and the ability to clearly view the entire operation through the safety shield further add to the user-friendliness.

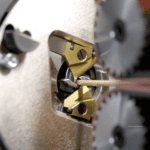

The UniCrimp 200 benchtop crimping machine is designed for crimping open or closed barrel terminals with up to 3.4 tons (33 kN) of crimp force. The machine easily handles wire sizes up to 6mm² (10 AWG) and accepts most standard mini-style applicators (mechanical or pneumatic) for crimping side- and rear-feed terminals. The UniCrimp 200 features a quick-release applicator base for easy changeover; adjustable crimp speed; standard tool-less, incremental crimp height adjustment (micro-adjust); and split-cycle capability for closed-barrel contacts. The machine provides the easy handling and fast cycle speeds required to increase the efficiency and quality of the crimping process. The machine is economical and user-friendly while providing an extremely quiet and safe operation.

The UniCrimp 200 benchtop crimping machine is designed for crimping open or closed barrel terminals with up to 3.4 tons (33 kN) of crimp force. The machine easily handles wire sizes up to 6mm² (10 AWG) and accepts most standard mini-style applicators (mechanical or pneumatic) for crimping side- and rear-feed terminals. The UniCrimp 200 features a quick-release applicator base for easy changeover; adjustable crimp speed; standard tool-less, incremental crimp height adjustment (micro-adjust); and split-cycle capability for closed-barrel contacts. The machine provides the easy handling and fast cycle speeds required to increase the efficiency and quality of the crimping process. The machine is economical and user-friendly while providing an extremely quiet and safe operation.

“With the purchase of Schleuniger equipment, our rejection rate dropped, as these machines eliminated all the possible errors in wire preparation, thus error-proofing the process,” said Manmohan Flora, manufacturing analyst at Kelvin Technologies’ Manufacturing.

In purchasing the ES 9300, the UC 200, and the US 2600, Kelvin saved production time and increased quality, as employees no longer needed to measure, cut, strip, and crimp the wires manually. With the US 2600’s ability to perform several steps in one ergonomic program, they gained flexibility for multi-conductor sensor cables. Not only does the machine process the specialized thermocouple cable, but the user may program the machine for different operations that make repeating production a cinch.

With these machines, Kelvin has a faster and more accurate production process that remains a simplified operation for the employee.[hr]

By Schleuniger and Kelvin Technologies

- Facts & Figures: Semiconductor Market Grew to a Record $336 Billion - March 2, 2015

- TLC and Metz Ethernet Cat 6A Patch Cords in Seven Vibrant Colors - January 27, 2014

- Cables Unlimited LC-LC Duplex Ruggedized Fiber Jumpers - January 27, 2014