What are Custom Connectors?

Meet the Connector: Custom Connectors

Despite the millions of commercial interconnects ready to serve every market and application type, certain situations call for something entirely, or just slightly, new.

When off-the-shelf connectors aren’t the right fit for a new application, custom solutions come into play.

Because connectors are often the last consideration in product design, OEM designers and engineers often require a custom connector solution to fit a particular application. The need for custom connectors may involve accommodating reduced size and weight, increasing connector packaging density for greater system capacity within existing space, performance improvements, or environmental requirements, said Brian Tea, sales manager, COAX Connectors. The solution might be to modify existing connector designs or to design a completely new connector.

“A connector manufacturer with a skilled design team as well as the right simulation and test equipment can speed up the process of designing a new connector or modifying an existing one quickly and cost-effectively,” Tea said.

COAX Connectors’ anti-rifling TNC connectors feature an ingenious two-part contact which allows for the expansion and contraction of the cable and contact material maintaining contact in extreme conditions. It can be customized to fit most standard RF cables, be plated in a variety of finishes such as White Bronze, Nickel or Black Nickel, and offers a choice of knurled or hex coupling nut.

What can be customized?

Any aspect of a connector can be customized; however, it is important to consider cost versus benefit when choosing to make these adjustments.

Materials – Connectors are impacted by various environmental conditions such as extreme temperatures or wide temperature swings and exposure to water, dust, or chemicals. The materials chosen for housing, insulation, and sealing must be appropriate for the conditions in which the connector will operate.

Form and fit – Connectors must fit into specific spaces and be designed with the right electrical capabilities for high speed, signal, and power. More and more applications require micro and nano connectors with greater pin density to support increased performance in a smaller form factor. Housing shape can be customized to fit a specific design.

Cable arrangement – Unique cable solutions may be required to accommodate power, data, and fiber.

Current rating – An application might require a higher current rating than is available from off-the-shelf connectors.

Contacts – Quality, pin count, density, arrangement, shielding, and plating can be customized to accommodate performance, high mating cycles, and signal integrity.

Plating – Plating affects performance, durability, life cycle, and cost. Gold plating is used for high-reliability, low-voltage, and low-current, high-cycle applications. Tin plating is a lower cost alternative with excellent solderability. Selective plating uses gold only in the contact area, providing an ideal combination of reliability and lower cost.

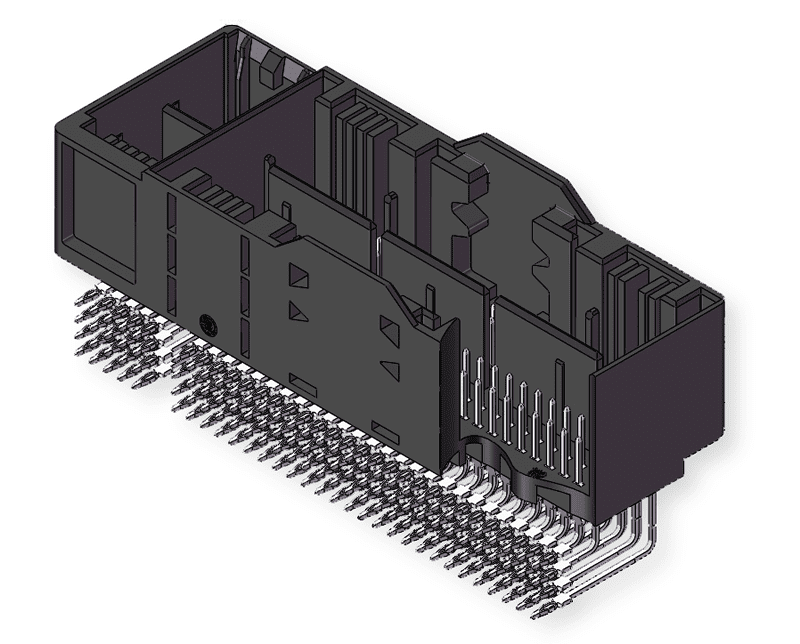

ept offers customization options to stagger pins, provide unique pin counts, add shielding, add power blades, modify to fit certain unique geometries, make custom injection molds, custom material usage and electroplating, and more.

How Connector Suppliers Provide Customization

Customization can be expensive and time consuming, but as the demand for custom connectors increases, many connector suppliers have developed innovative solutions that deliver custom or semi-custom connectors quicker and more cost-effectively.

3D printing and additive manufacturing

Ideal for establishing the form and fit of a connector, 3D-printed parts are not typically fully functional. However, 3D-printed molds can produce fully functional parts for design and testing.

Amphenol Pcd’s Rapid Part Development process uses 3D-printed molds to create functional customized parts for designs in aviation applications. Shown here: Fairlead block (left) and lightening hole bushing.

Value-add custom assemblies

Distributor PEI-Genesis “value-adds” 70% of the products it sells. The company stocks grommets, shells, contacts, and other individual connector components and builds the final product to meet customer requirements using automated and manual processes.

Phoenix Contact offers multiple DIN rail solutions that reduce assembly time, inventory, and wiring errors with single part number ordering. DIN rail cut to the customer’s specified lengths and hole placements, as well as fully customized DIN rail assemblies, are available. Phoenix Contact will build customer-designed junction boxes, backplates, and cable harnesses, or assist in kitting multiple Phoenix Contact components under one part number.

Custom connectivity products are available from many suppliers. To learn more about customizing, visit the Preferred Supplier pages for Amphenol Pcd, Bulgin Components, CDM Electronics Inc., COAX Connectors, EDAC, ept connectors, Fischer Connectors, Lumberg, PEI Genesis, Phoenix Contact, Positronic, PRECI-DIP, Samtec Inc., SOS Engineering, and Times Microwave Systems.

Like this article? Check out our other Meet the Connector and Custom connector articles, our Special Topics Page, and our 2023 and 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024