What are Expanded Beam Connectors?

Meet the Connector: Expanded Beam Connectors

Datacom and telecom systems originally relied on physical contact fiber optic connectors, which worked well in data centers and other controlled, protected locations. As the need for this type of connection extended to rugged environments, such as civil and military aerospace, military ground applications, naval systems, industrial sites, and offshore environments, expanded beam connectors were developed to withstand the challenges of harsh conditions.

How it works

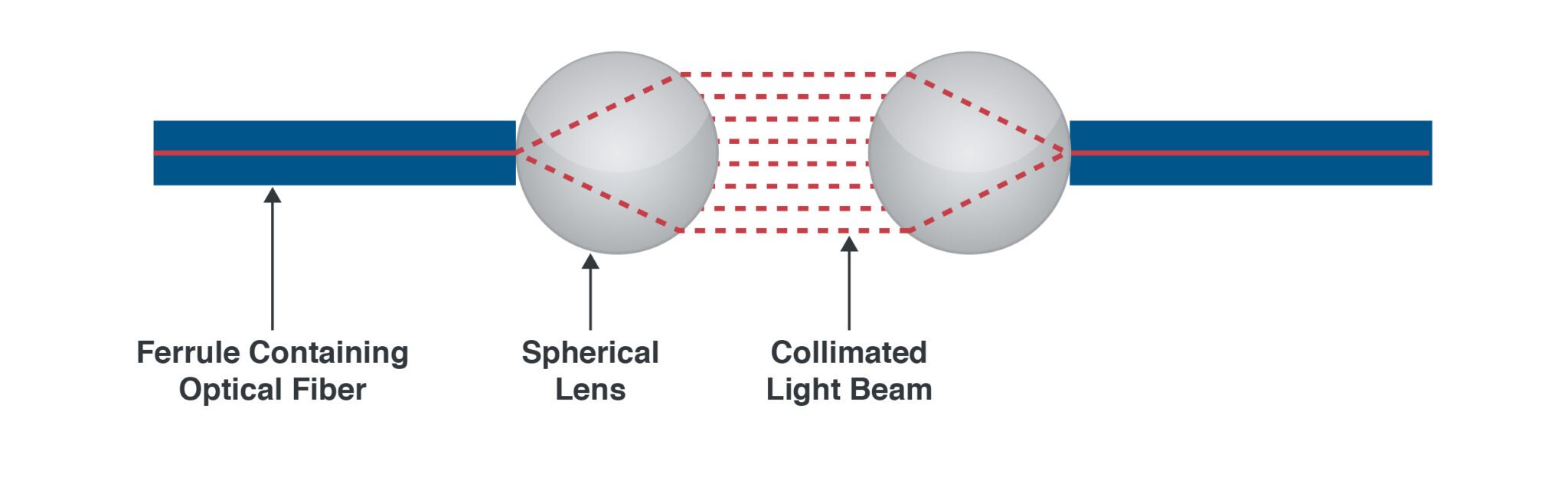

Expanded beam fiber optic connectors utilize a lens to expand and collimate the light emitting from an optical fiber. The collimated light beam is transmitted through an air gap to a mating connector, where the light is collected and focused by a second lens into a second optical fiber to complete the connection.

Diagram of expanded beam components and operation. Credit: Cinch Connectivity Solutions

Advantages of expanded beam

Expanded beam fiber optic connectors have several advantages over physical contact connectors in harsh environments.

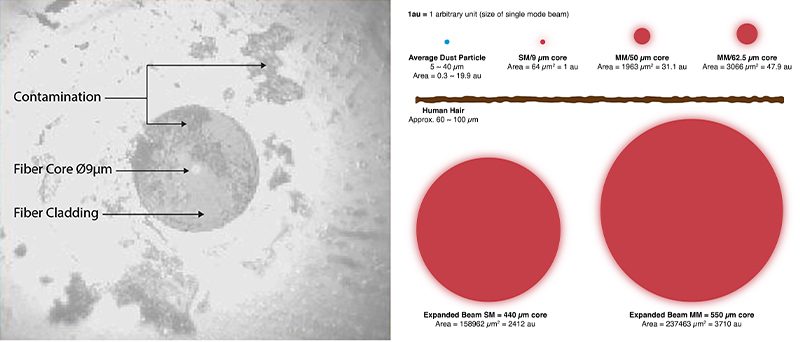

When a physical contact connector is unmated, the highly polished ferrule ends are exposed to dirt and debris that can get on the fiber optic end-face. Then, when the connector is mated, that debris can damage the sub-micron polished finish and deteriorate the connector’s optical performance. This is a particular risk in high vibration applications. The expanded beam connector has a non-contact design with a lens that completely seals the fiber optics and enlarges the beam diameter. The air gap created between the mated lenses ensures any debris present on the lenses does not cause damage during operation or vibration, greatly improving the connector’s reliability in tough conditions.

View on a physical contact termini end-face at 200x magnification showing typical contamination from dust and oily deposits. (Right) Comparison of EB core size to other fiber types and dust particles. Source: Cinch Connectivity Solutions

In addition, expanded beam connectors have greater tolerance for misalignment that results from shock and vibration. They are easier to maintain and clean.

Design Notes

Standardization

Expanded beam fiber optic connectors are included in MIL-DTL-83526, the military specification describing the characteristics, performance, and testing criteria for an environmental resistant, fiber-optic circular connector with hermaphroditic interface. The standard covers connectors with consistent and predictable optical performance using low loss optical fiber cables in ground- based fiber-optic data transmission systems that are rugged enough for military field applications.

Contacts

Expanded beam is a non-contact fiber technology. Light passes through a small gap between two lenses.

Termination

Expanded beam connectors can be factory pre-terminated or terminated in the field using standard epoxy-polish techniques.

Modes

Expanded beam connectors can be single-mode (core size approximately 8.3 µm; light travels along the fiber in a single pathway) or multi-mode (core size ranges from 50 µm to 62.5 µm; light travels through the optical fiber along various paths). They are typically available in fiber counts of 2 to 16 fibers.

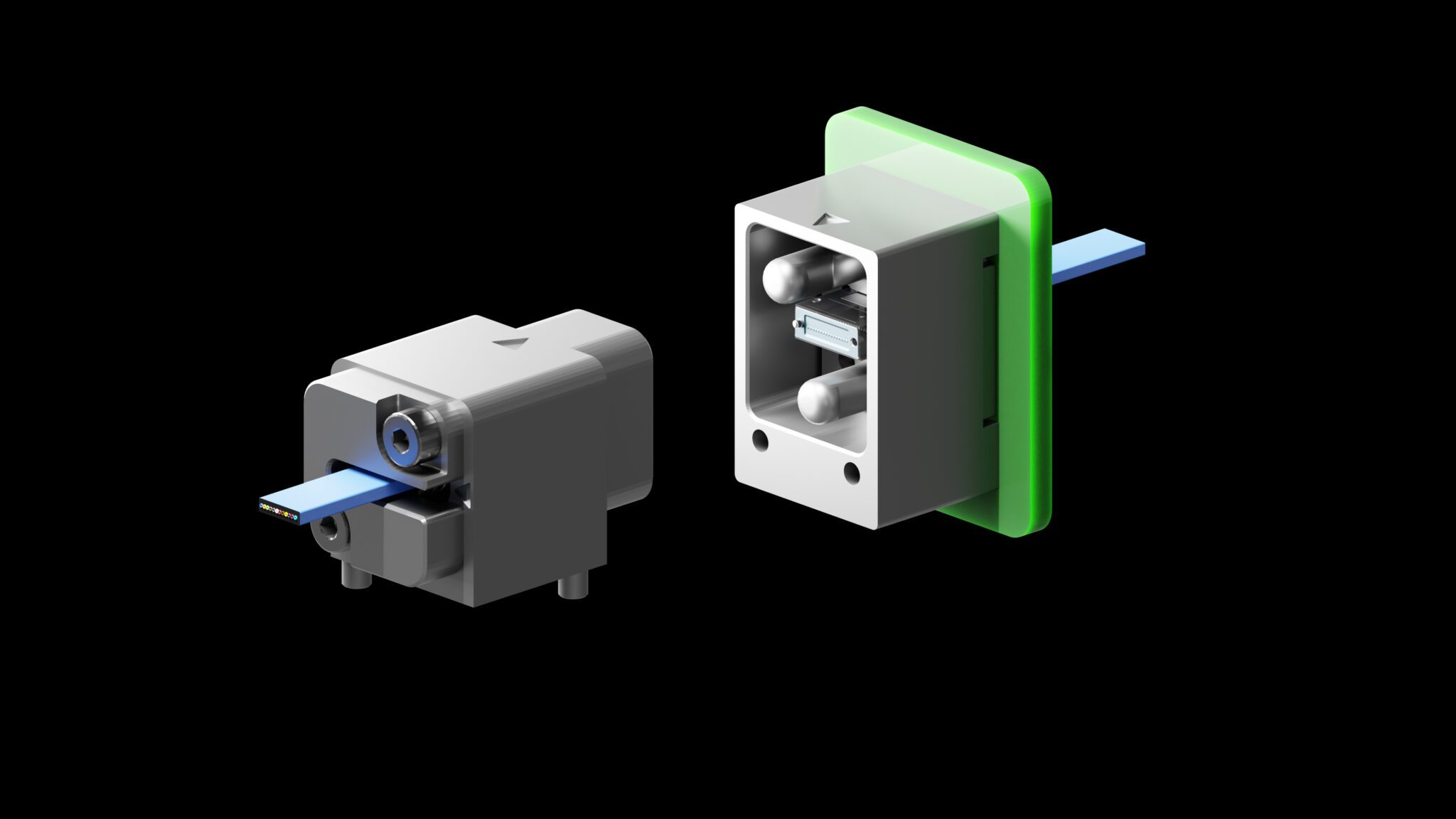

Cinch Connectivity Solutions Fibreco fiber optic connectors and cable assemblies offer high performance, flexible, cost-effective solutions to any critical harsh environment communication application.

Markets and Applications

Markets include Datacom/Telecom, MIL-Aero, Industrial

Expanded beam connectors are specifically designed for harsh environment applications. They are widely used in military tactical communications, outside broadcast, mining, offshore, and many industrial applications.

Suppliers

Expanded beam connectors are available in many variations from many suppliers, including: Bulgin, Cinch Connectivity Solutions, Nicomatic, HARTING, Rosenberger, TE Connectivity, ODU, 3M, and others.

Related products

- Fiber optic connectors

- MPO Fiber Optic Connectors

- MIL-DTL-83526 connectors

Like this article? Check out our other Meet the Connector and Networking articles, our Harsh Environment Articles, and our 2023 and 2024 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024