Soldier Wearables Provide Safety and Connectivity

Protecting soldiers, law enforcement, and first responders is easier with new connected communications, navigation, armoring, and tactical wearables. Component interoperability makes it possible to link different equipment makers, eras, and units.

Soldier wearables have emerged as crucial tools for enhancing operational effectiveness, situational awareness, and personal safety. Soldier wearables are the link between troops, units, leaders, and logistics networks that integrate intelligence, supplies, and support throughout the command hierarchy. These devices take the form of smart helmets and headsets, body armor, smartwatches and biometric monitors, augmented reality goggles, navigation tools, computing and communication equipment, and power and energy management devices. At the heart of these networks, interconnects ensure seamless data transmission and reliable power supply even under warfare conditions.

Military wearables aren’t a new concept; during World War II, soldiers carried two-way radios on their bodies, night vision goggles were first used in the Vietnam War, and in the 1990s, the Land Warrior program brought wearable computers and a helmet-mounted display to the U.S. Army. Since then, soldier wearables have proliferated, including the Nett Warrior suite of technologies and Integrated Visual Augmentation System (IVAS) in the U.S.; the Future Soldier program in Europe; the Ratnik program in Russia; QTS-11 in China; and similar programs in Canada, Israel, UAE, and other countries. These devices empower individual soldiers with access to real-time, encrypted communications that enhance personal protection and provide more precise instructions, conveyed instantly across RF communication channels, Bluetooth, Wi-Fi, SATCOM, mesh networks, and wired connections.

Interoperability between forces

While Nett Warrior is a U.S. program, interoperability is a key consideration in the development and deployment of military wearables, as interoperability with NATO and allied forces ensure seamless communication and coordination during joint exercises and operations. Interoperability with NATO Standardization Agreements (STANAGs) and other systems is crucial for effective coalition warfare. Nett Warrior uses standardized connectors and interfaces to facilitate interoperability with a wide range of equipment, including sensors, radios, and other wearables. The modularity of Nett Warrior allows for components to be easily swapped out or upgraded to meet different operational requirements and to integrate with other systems used by NATO forces.

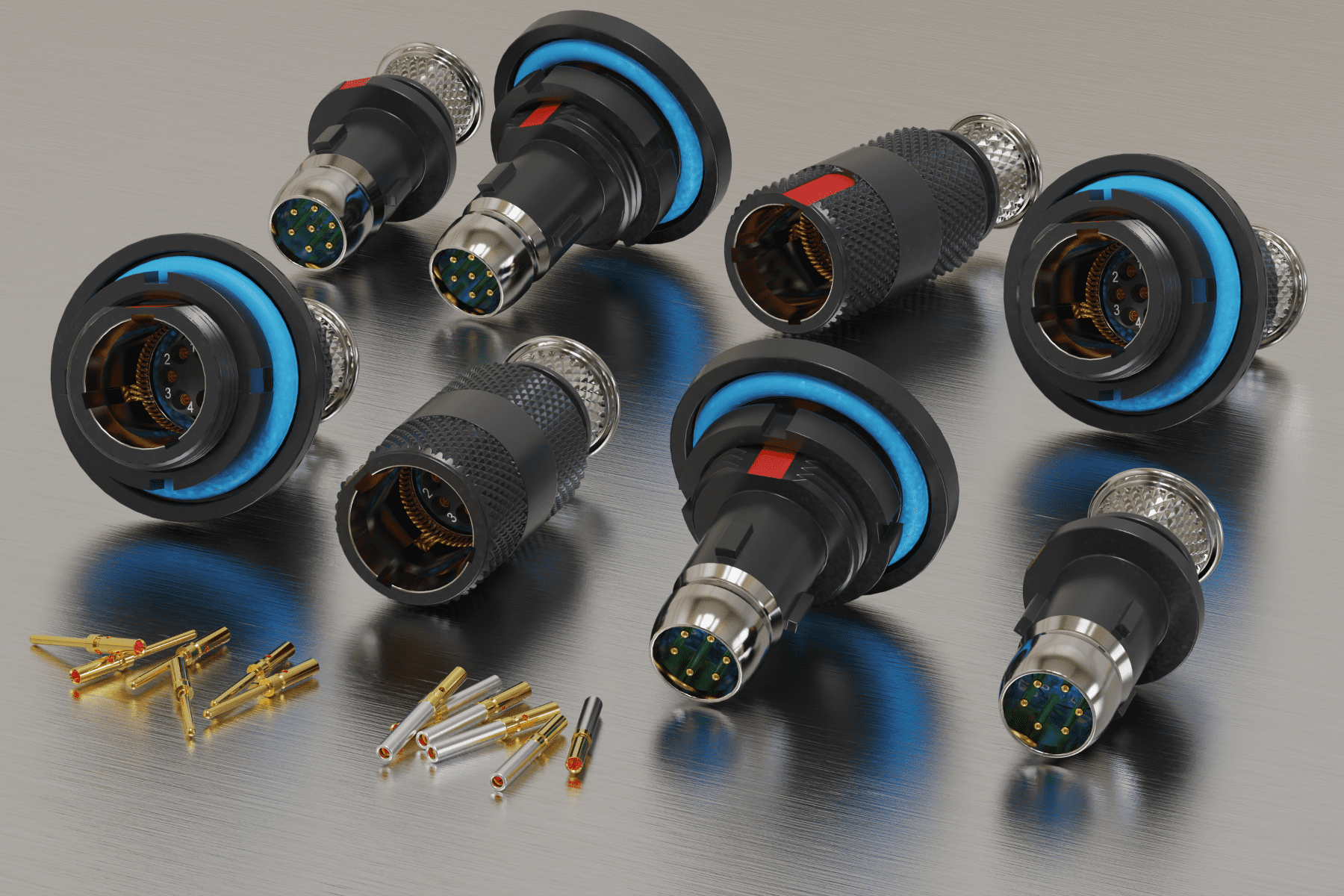

Omnetics Connector Corporation developed the Kilo 360 Warrior Series Connectors to provide interoperability between various forces using equipment with micro miniature 38999 interconnects. New 10 Amp receptacles are available for higher-current soldier battery charging, radio, and C4ISR equipment.

Perhaps no other connector is as important to military wearables as the micro miniature 38999 circular connector. The connectors are used in radios, goggles, headsets, vest-worn computing equipment, battery packs, and other tactical soldier wearables. Interoperability enables different types of equipment from different makers and for different militaries to be connected using a common connector. “Omnetics has developed the Kilo 360 Warrior Series Connectors with a commitment to compatibility while addressing the SwaP, ruggedization, and integration requirements of the various components,” says Scott Unzen, Omnetics director of marketing and market development. “This connector series has been designed and tested to the Nett Warrior specifications and is fully intermatable to the existing Nett Warrior approved connectors.”

The Kilo 360 product is not a replica of existing interfaces; it incorporates proprietary design elements to become the industry’s most fully compatible interface with existing equipment, said Unzen. Three families of interfaces — double start, push-pull breakaway, and triple start threaded — feature enhanced shielding as well as the latest design and materials considerations to limit size and weight while delivering exceptional durability.

“It’s the biggest one out there in terms of soldier wearables, although some devices are using ruggedized UBC-Cs for things like the Juggernaut cases,” said Unzen, who doesn’t see that changing soon, although future AI and AR technologies could test the limits of the 38999. “At that point, we will be looking at fiber for those higher speeds. Optics have come a long way as far as ruggedness goes; Corning has a cable product that you can actually tie in a knot, so as AI technology matures in the military space, we’ll see more optical components come into play.”

Connectivity in action environments

Ideally, cables won’t get tied in knots, but the latest generation of high speed, small form factor cabling is ready for action. Flexible and lightweight cabling is critical for soldier wearables as well as similar wearable technologies that have moved from military to civilian applications. Police, first responders, and industrial workers, like soldiers, are in constant motion, and equipment for these fields must adhere to size, weight, and power guidelines. Multi-conductor cables with a lightweight jacket, often made of materials like polyurethane (PU) or thermoplastic elastomer (TPE) are specified for many wearables. To maintain security and reduce interference between the various types of equipment, shielded and single-twisted-pair formats are commonly used. Sensor and communications applications may use micro-coax cabling.

Ruggedized options such as overmolding, cable braiding, and shielding help these assemblies perform in tough conditions. Equipment may be tossed into packs, worn in all weather, and experience shock and vibration. Connectors are secured with mechanical and chemical means, and backshells add protection from moisture, dust, and mechanical stress. Assemblies that include strain relief can improve the overall durability of the connection.

AirBorn offers cable assemblies for soldier wearables with ruggedized options such as overmolding, cable braiding, and shielding.

Streamlined wearable equipment for military and first responders

The proliferation of C4ISR devices in both the military and for civilian police and first response teams has added weight and increased the challenge of managing data and battery power efficiently. To enable users to connect and power their digital gear easily and reliably, Fischer Connectors developed a wearable power and data hub, Fischer KEYSTONE.

The prototype police tactical vest co-developed by Wearin’ and France’s General Directorate of the National Gendarmerie (DGGN) offers optimal ergonomics and physical-and-digital integration of the warning-and-communication devices worn by gendarmes. “Gendarmes” are police officers belonging to the French armed forces. (Images: @Conextivity 2024)

The new tactical hub is an easily deployable MIL-Spec solution to the tactical connectivity challenge presented by digital modernization programs, i.e., more data, higher speeds, greater power, and less weight in harsh environments. Intermateable with Nett Warrior and NATO STANAG 4695/4851 interfaces, the Fischer KEYSTONE™ Tactical Hub series ensures seamless integration with existing systems, enhancing warfighter situational awareness and contributing to overall operational efficiency within the Battlefield Management System (BMS) framework. The series comprises a 6-port tactical hub, Fischer KEYSTONE 6, a power management app plug-in for the Android Team Awareness Kit (ATAK), and customized cable assemblies with Fischer UltiMate 80 connectors. Compact and IP68-sealed, the plug-and-play Fischer KEYSTONE version with 4 ports launched in March 2024, Fischer KEYSTONE 4, empowers soldier mission in offering an unmatched combination of compactness, ruggedness and performance in the soldier hub marketplace, enhancing in particular the mission of fast-moving special operation forces and small-squad team leaders. The housing of KEYSTONE 4 is 69.2 mm long, 38 mm wide, 17 mm thick, weighs 125 g, and is sealed, along with its connectors and cable assemblies, to IP68 for -2m/24. Other environmental MIL-STD-810G features include operating temperature from -32 °C to +55 °C, operating altitude up to +9,754 m, and resistance to shock of 40 G / 11 ms, to vibration of 7.7 Grms / 1 h per axis, and to weather conditions such as solar radiation, salt, sand and dust, rain and water, and fungus.

Both Fischer KEYSTONE hubs with 6 and 4 ports benefit from a versatile suite of cable assemblies including extensions, adaptors, as well as assemblies interconnecting EUD, radios, and a variety of other C4ISR devices (Images: @Conextivity 2024)

Part of Conextivity Group along with Fischer Connectors, Wearin’ uses the Fischer KEYSTONE 4 in one of its IoT prototype solutions that connect the tactical vest worn by field personnel with the command center of police force (e.g., the French Gendarmerie which belongs to French armed forces), firefighters, first responders, and lone workers. The tactical vest functions as an intelligent IoT platform, capturing in-mission data from connected sensors and devices. A range of sensors and devices are built into the vest and monitor conditions inside and outside of the personnel in the field, including air quality and gases, proximity and falls, high voltage, noise, temperature, and biometrics. Other wearables, such as GPS, radios, and cameras, can be integrated into the vest or wirelessly connected.

Wearable technologies have become an essential part of military and first responder gear. They are integrated into uniforms, providing critical communications and information, and working in concert with multiple systems to keep the individual safe and supported in challenging environments. This equipment is constantly evolving, and new devices will integrate augmented (AR) and virtual reality, Initiatives like IVAS will use AR to enhance soldiers’ perception of their environment. Biometric systems will help monitor and protect them from physical stressors such as heat and dehydration. Future soldier wearables will employ even more technology to enable military personnel to better perceive battlefield conditions, react to changing elements, and remain connected to their organizations.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for AirBorn, Fischer Connectors, and Omnetics Connector Corporation.

Like this article? Check out our other Technology Trends, Mil/Aero Market articles, and our 2024 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- What’s the Forecast? New Connector Industry Sales Report - June 25, 2024

- Soldier Wearables Provide Safety and Connectivity - May 28, 2024

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024