What are Nano-D connectors?

Meet the Connector: Nano-D

Nano-D connectors, along with micro-D connectors, were developed in the 1970s as a variation of D-sub (D-subminiature) connectors. ITT Cannon (formerly Cannon) holds the trademark for the D-sub and its smaller variants, although other companies have since designed their own versions. Like the micro-D and D subs connectors before it, the nano-D gets its name from its shape, which resembles the letter D.

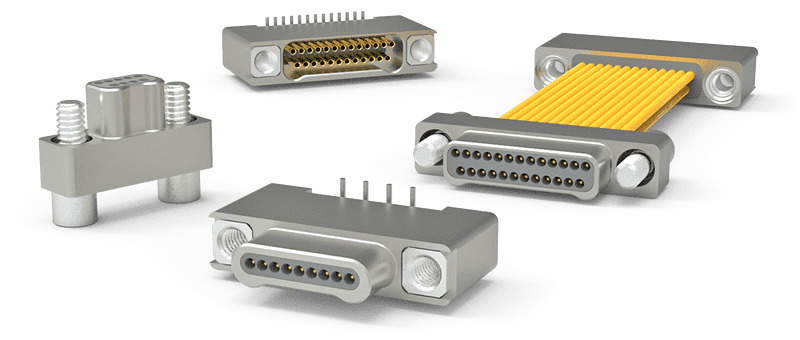

AirBorn’s N Series interconnects are a high-density, high-reliability connector line used in a wide variety of mission-critical applications where size and weight are essential. N-Series’ tiny footprint frees up real estate on the PCB, within the cable harness, or on any electronic unit. N-Series’ 3 points-of-contact system ensures contact is maintained no matter how rough the ride. High-vibration and temperature resistance sets N Series apart.

According to Omnetics Connector Corporation, the military’s push for interconnects that meet SWaP (size, weight, and power) requirements led to the development of MIL-DTL-32139 nano-D connectors that are equivalent to MIL-DTL-83513 connectors. The nano-D is about half the size of the micro-D, and about one-quarter the size of the D-sub. At 12g, a 25-position nano-D weighs 12g and has one-eighth the volume of a comparable 25-position micro-D.

Omnetics Connector Corporation offers a variety of Bi-Lobe/Nano-D connectors, including single row, latching, dual row, and panel mount.

Design Notes

Standardization: Many suppliers, including AirBorn, Axon Cable, Glenair, and Omnetics Connector Corporation offer nano-D connectors that meet MIL-DTL-32139 specifications.

Size: Nano-Ds are the smallest of the D-shaped connectors. They are roughly half the size, one-quarter of the weight, and one-eighth the volume of comparable micro-Ds.

Pitch: The pitch for Nano-D connectors is set at .025” (0.64mm) pin-to-pin spacing.

Locking mechanisms: Some nano-Ds, such as Omnetics’ latching nano-D connectors and Axon’s nano-D fast-lock connectors, have locking mechanisms that eliminate the need for screws and tools.

Axon’ Cable offers nano-D connectors and jumpers based on the highly reliable twist-pin contact technology. Nanominiature connectors are based on the nano-D technology with 0.635 mm (.025″) contact spacing and nanominiature shells. Performances are based on the MIL-DTL-32139 specification.

Shielding: Backshells can connect shielded braiding from cable to shells, protecting against EMI and crosstalk. Slip-on shielding offers 60 db of protection. Tighter shield windings using smaller diameter gold-plated strands offer up to 90 db of shielding from exterior signal ingression.

Mating: The Nano-D military specification requires 200 mates before plating failure increases the resistance of the connection. Some nano-D connector suppliers offer over 2,000 mates before plating fails, extending the connectors useful life in applications that require frequent connections.

Plating: The recommended plating is specified to meet ASTBM B488 Type II, which includes 50 micro-inches of gold over 50 micro-inches of nickel.

Temperature Range: For MIL-STD-32139 nano-D connectors, the range is -55 °C / +150 °C (standard) and -55 °C / +200 °C (high temperature).

Durability: Due to their low weight and small size, nano-D connectors are better than micro-Ds at withstanding shock and vibration. Nano-Ds have been used in high shock conditions (above 10,000G).

Markets, Sectors, and Applications

Nano-D connectors are widely used in military and aerospace applications where small size and light weight are critical. They are also found in robotics, unmanned aerial vehicles, air taxis, satellites, petrochemical applications, and medical devices.

ITT Cannon’s NDD M32139-style nano-D is a small form factor, high density interconnect designed and manufactured for high reliability and harsh environment applications. These interconnects are ideal when size and weight limitations require an ultra-low profile and robust design package. Utilizing the innovative twist pin contact system on 0.025” contact spacing and five points of electrical contact, the NDD series offers an extremely rugged small form factor interconnect solution.

Suppliers

AirBorn, Axon Cable, Glenair, ITT Cannon, and Omnetics Connector Corporation.

Related Products:

Like this article? Check out our other Meet the Connector and Miniaturization articles, our Military/Aerospace Market Page, and our 2023 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024