Design Planning to Insure Performance in Harsh Environments

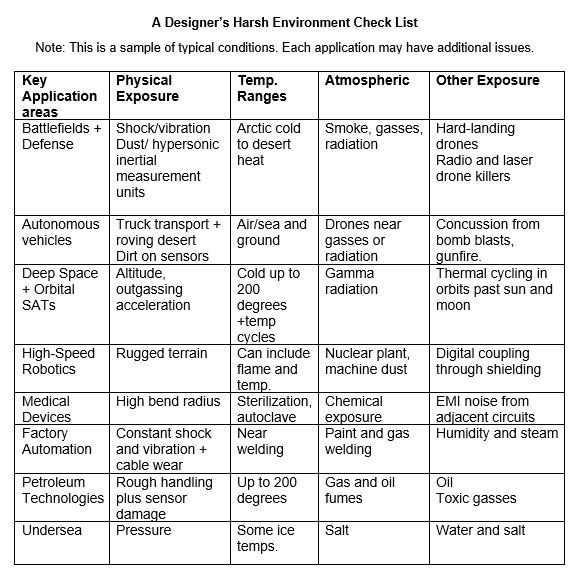

The range and expansion of electronic applications today has extended the need for analysis and preparation of circuit designs to survive new operating settings in extreme harsh environments. Navigation electronics that have been employed in automobiles for navigating our city streets are now playing a role in deep space exploration. As technologies move into new environments, diligent planning is required to ensure the design format and material selection for these advanced systems can endure the challenging conditions they will face.

A wide range of connector and cable systems support the data acquisition, processing, and signal routing in these new circuits. Often, the connectors and cable harnesses are exposed to the most extreme environmental conditions surrounding the application. Exterior sensors, camera systems, and extended arms or robotics often operate outside of the main equipment structure. The interconnects involved must be designed to withstand very rugged treatment.

Autonomous Weapon

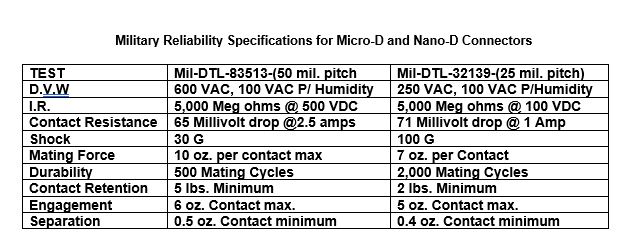

Experienced interconnect designers can assist in the planning and building of electronic systems that can help ensure performance and longevity for the whole unit. Key planning steps should include a thorough awareness of the environmental dangers the products may encounter. This should include a review of NEMA environmental standards, including IP code 250, which covers hazardous and environmental exposure. Products that meet military standard specifications can provide additional reassurance. Highly portable, rugged, and reliable MIL-DTL-83513 Micro-D connectors are a very popular choice for harsh environment applications. Micro-D subminiature connectors with pin-to-pin center spacing at .050” (1.27 mm) provide powerful connectivity in a very small format. MIL-DTL-32139 for Nano-D, nanominiature rectangular, connectors with pin-to-pin center spacing at .025” (0.635 mm) are another popular choice for small, lightweight connectivity. An overall guidance specification for higher reliability in harsh environments is listed as MIL-STD. Number 790 and is updated by the U.S. Defense Labs as technologies evolve.

Harsh environment connector designs depend on rugged materials, durable physical forms, and interfaces that can protect the connector pin to socket in the event of high shock and vibration and other environmental attacks. As circuit and sensor electronics evolve, they get smaller and operate faster on low voltages and currents. Micro and nano connectors are becoming the standard interface from cable to board or cable to instrument because they are lightweight and absorb high vibration and or shock conditions.

In many instances, the new equipment operating in extreme environments is detecting, collecting, and processing massive amounts of data without human involvement. These technologies are rapidly pushing beyond 10 Gb/s. To achieve these high speeds, digital signals are designed to operate at very short signal rise time. This is accomplished with higher-speed chip technologies such as GaAs and Gallium Nitride, which also operate at lower voltages. As a result, the short signal rise time and low-voltage signals flow on very short signal lengths at minimal heights. These new mini-digital signals must be carefully protected, both physically and electrically, from interference. For example, cable wiring is often designed to carry the positive and negative digital signals on separate wire pairs that run in parallel with their ground return wire. Each signal set is protected and wrapped in insulation and then shielded from outside electrical elements.

In many instances, the new equipment operating in extreme environments is detecting, collecting, and processing massive amounts of data without human involvement. These technologies are rapidly pushing beyond 10 Gb/s. To achieve these high speeds, digital signals are designed to operate at very short signal rise time. This is accomplished with higher-speed chip technologies such as GaAs and Gallium Nitride, which also operate at lower voltages. As a result, the short signal rise time and low-voltage signals flow on very short signal lengths at minimal heights. These new mini-digital signals must be carefully protected, both physically and electrically, from interference. For example, cable wiring is often designed to carry the positive and negative digital signals on separate wire pairs that run in parallel with their ground return wire. Each signal set is protected and wrapped in insulation and then shielded from outside electrical elements.

Digital cables used in extreme environments can be protected with polymer jackets that provide strain relief. This jacketing can survive heat cycles. With the addition of metal braided shielding, cables can be physically protected and shielded from electronic signal interference.

Ruggedized circular connectors from Omnetics

In space-constrained applications that experience repetitive motion, the cable may need to be small in diameter yet also be strong, resilient, and flexible enough to accommodate constant bending and folding. For example, high-speed assembly robots are now performing many assembly tasks in the automotive industry. If the cable and connector are not designed properly, wear and tear on the interconnects can impact automated systems and shut down the assembly line.

Prior to connector and cable selection, designers should review potential exposure.

The complete design, manufacturing, and testing process

Review the application and potential harsh conditions using the checklist above.

- Begin work with a MIL-quality level interconnect company that has experience in similar applications and can offer design consulting. A company that can interactively use solid modeling can help tailor existing high-reliability designs to fit the device.

Shielded Micro-D and Nano-D from Omnetics

- Review harsh-environmental requirements with the connector and cable supplier to ensure the appropriate cable, metals, plating, and polymers fit within the application. (For example, outgassing levels of epoxies must meet NASA specifications if the component is used in space applications.)

- When the first solid models are ready, request delivery of a 3D prototype to insure both cable and connectors fit within the design.

- When the final interconnect is approved for size, shape, materials, and construction, have multiple sets built up for harsh environment reliability testing.

- Have harsh environment testing performed by a test lab that has many years of experience with multiple test processes that replicate the extreme variables connectors face in harsh environments.

A wide range of environmental testing should be done, including exposure to mixed flowing gas, humidity, temperature, salt fog, dust, and thermal cycling. Testing for shock and vibration using drum-like systems can mimic aircraft and drone vibrations. Testing components for corrosive reactions, moisture resistance, temperatures at altitude, and plating durability helps ensure the product will perform reliably in its expected operational setting.

Harsh connector planning and design is a well-worn path to achieving high reliability interconnection systems. Designers have multiple resources available to ensure products not only survive the rigors of extreme use but can improve their system performance. For assistance, designers can review examples of connectors that have already passed these tests in existing harsh environment applications ranging from space and defense to medical applications.

Visit Omnetics Connector Corporation to learn more.

Like this article? Check out our other How to Specify, Mil/Aero Market articles, and our 2023 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Design Planning to Insure Performance in Harsh Environments - January 23, 2024