Overmolded Assemblies Product Roundup

This week’s Product Roundup highlights overmolded assemblies from leading suppliers.

Overmolded assemblies

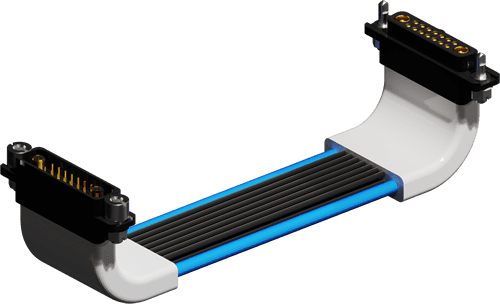

Nicomatic specializes in cable overmolding to provide optimal protection for electronic assemblies. Two overmolding options are available: flexible overmolding made of silicone-based resin and rigid overmolding achieved through low-pressure injection and hotmelt. Nicomatic’s solution follows MIL-STD-83513 performance standards, meets the constraints of severe temperature environments, and can be waterproof if necessary. In terms of wiring, Nicomatic has received an “A” rating from Thales and complies with EN9100 and ISO9001 standards.

Nicomatic specializes in cable overmolding to provide optimal protection for electronic assemblies. Two overmolding options are available: flexible overmolding made of silicone-based resin and rigid overmolding achieved through low-pressure injection and hotmelt. Nicomatic’s solution follows MIL-STD-83513 performance standards, meets the constraints of severe temperature environments, and can be waterproof if necessary. In terms of wiring, Nicomatic has received an “A” rating from Thales and complies with EN9100 and ISO9001 standards.

Axon’ Cable manufactures overmolded assemblies for any market. Axon’ overmolding provides robust and tailor-made mechanical protection, particularly for the cable/connector interface, which is traditionally the weakest point of cable assemblies. The experts at Axon’ can assist with designing the ideal solution for your needs by addressing a number of key considerations, including space-saving with custom shapes, strain relief, sealing (airtightness, watertightness), absorption of repeated flexes, provision of fixing points, protection of shielding termination (EMC), improvement of the overall look of the harness, integration of links or parts into the customer’s system, customized contact overmolding for higher performance compared to a standardized connector, integration of electronic functions (e.g. signal conversion) in cable assemblies, and customized interconnect solutions.

Axon’ Cable manufactures overmolded assemblies for any market. Axon’ overmolding provides robust and tailor-made mechanical protection, particularly for the cable/connector interface, which is traditionally the weakest point of cable assemblies. The experts at Axon’ can assist with designing the ideal solution for your needs by addressing a number of key considerations, including space-saving with custom shapes, strain relief, sealing (airtightness, watertightness), absorption of repeated flexes, provision of fixing points, protection of shielding termination (EMC), improvement of the overall look of the harness, integration of links or parts into the customer’s system, customized contact overmolding for higher performance compared to a standardized connector, integration of electronic functions (e.g. signal conversion) in cable assemblies, and customized interconnect solutions.

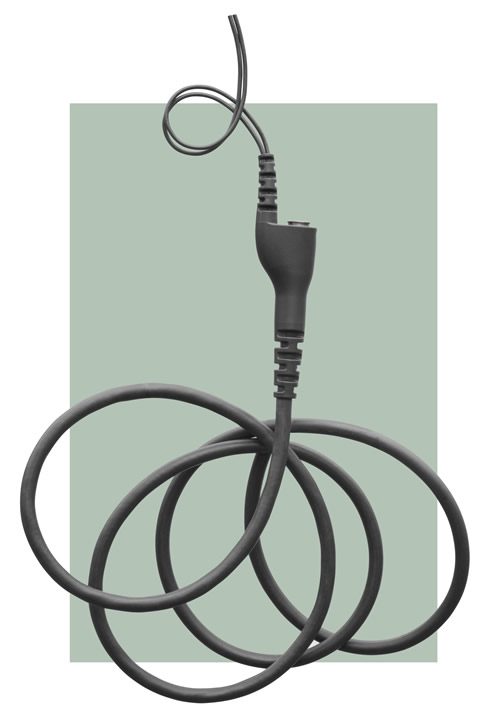

Switchcraft Off-the-Shelf (OTS) DC Power Jack Cables from Heilind offer a 300V rating, a 20AWG wire, and UV- and water-resistant construction. The OTS DC power plug is a single-ended cable with stripped and tinned leads, with color-coded, tissue-paper-separated conductor wires. Switchcraft OTS DC Power Jack Cables have a -30 °C to +105 °C operating temperature range and a 24VDC resistive voltage rating. The molded 360° Flex Relief technology allows for the maximum amount of flexibility and movability.

Switchcraft Off-the-Shelf (OTS) DC Power Jack Cables from Heilind offer a 300V rating, a 20AWG wire, and UV- and water-resistant construction. The OTS DC power plug is a single-ended cable with stripped and tinned leads, with color-coded, tissue-paper-separated conductor wires. Switchcraft OTS DC Power Jack Cables have a -30 °C to +105 °C operating temperature range and a 24VDC resistive voltage rating. The molded 360° Flex Relief technology allows for the maximum amount of flexibility and movability.

Omnetics nano series of circular connectors is now available in a break-away configuration. These connectors are the smallest Mil-Quality circulars available today. With the ability to withstand high shock and vibrations while maintaining electrical integrity, the break-away feature is ideal for the most demanding applications where size and ruggedness are valued. Designed with an extra retention spring, these connectors are engineered to release (break away) at a pre-determined force. These connectors are also available with added waterproof sealing up to IP68 for the mated pair. Omnetics provides an overmold for its standard or custom-designed connectors.

Omnetics nano series of circular connectors is now available in a break-away configuration. These connectors are the smallest Mil-Quality circulars available today. With the ability to withstand high shock and vibrations while maintaining electrical integrity, the break-away feature is ideal for the most demanding applications where size and ruggedness are valued. Designed with an extra retention spring, these connectors are engineered to release (break away) at a pre-determined force. These connectors are also available with added waterproof sealing up to IP68 for the mated pair. Omnetics provides an overmold for its standard or custom-designed connectors.

Kensington Electronics manufactures all cable assemblies and overmolds in the U.S. By keeping your job local, Kensington can guarantee transparency in the engineering process, design, and manufacturing process. On top of that, Kensington’s in-house design engineer is on-hand to help with design and testing requirements. Overmolding offers 360° strain relief and enhances pull strength. Aesthetically, an overmold creates a seamless piece to create a cleaner look. Overmolded cables provide additional protection against harsh environments.

Kensington Electronics manufactures all cable assemblies and overmolds in the U.S. By keeping your job local, Kensington can guarantee transparency in the engineering process, design, and manufacturing process. On top of that, Kensington’s in-house design engineer is on-hand to help with design and testing requirements. Overmolding offers 360° strain relief and enhances pull strength. Aesthetically, an overmold creates a seamless piece to create a cleaner look. Overmolded cables provide additional protection against harsh environments.

The Trexon Engineered Products Division (EP) collective brands provide a variety of high-performance wire and cable solutions with overmolding capabilities, from extruded flat cable to ruggedized harnesses. Options for RFI/EMI shielding of cables prior to overmolding are available. Trexon’s key brands offer the following capabilities: Cicoil offers extruded flat cables – silicone; The First Electronics Corporation (FEC) offers injection, compression, transfer, and low-pressure over-molding (polyurethane, neoprene, Viton, and EPDM rubber overmolding; Hydro Group offers polyurethane (PU), polyethylene (PE), PVC, Hytrel, and neoprene; Integrated Cable Systems (ICS) offers plastic mold injection, custom molding, and thermoplastic polymers.

The Trexon Engineered Products Division (EP) collective brands provide a variety of high-performance wire and cable solutions with overmolding capabilities, from extruded flat cable to ruggedized harnesses. Options for RFI/EMI shielding of cables prior to overmolding are available. Trexon’s key brands offer the following capabilities: Cicoil offers extruded flat cables – silicone; The First Electronics Corporation (FEC) offers injection, compression, transfer, and low-pressure over-molding (polyurethane, neoprene, Viton, and EPDM rubber overmolding; Hydro Group offers polyurethane (PU), polyethylene (PE), PVC, Hytrel, and neoprene; Integrated Cable Systems (ICS) offers plastic mold injection, custom molding, and thermoplastic polymers.

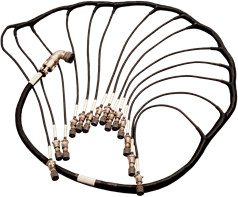

SV Microwave’s line of strain relief cable assemblies features a molded boot to protect the sensitive cable termination area and allow for more flexibility and peace of mind. Additionally, these cable assemblies feature SV’s Ø.087″ Low Loss cable type that provides slightly more flexibility and less insertion loss than its standard Ø.085″ cable. These test cable assemblies are available with male SMA, 2.92 mm, or 2.4 mm connector series.

SV Microwave’s line of strain relief cable assemblies features a molded boot to protect the sensitive cable termination area and allow for more flexibility and peace of mind. Additionally, these cable assemblies feature SV’s Ø.087″ Low Loss cable type that provides slightly more flexibility and less insertion loss than its standard Ø.085″ cable. These test cable assemblies are available with male SMA, 2.92 mm, or 2.4 mm connector series.

Avnet’s expert engineers and designers provide custom cable and interconnect designs. Working with Avnet saves you from having to invest in tooling, manufacturing space, and labor to accomplish this on your own.

Avnet’s expert engineers and designers provide custom cable and interconnect designs. Working with Avnet saves you from having to invest in tooling, manufacturing space, and labor to accomplish this on your own.

Amphenol’s OCP-compliant AC Input Connectors and Cable Assemblies are designed to meet OCP’s V3 Universal Input power distribution architecture standards and provide a convenient method of routing power directly from the busway to the power shelf within the V3 rack. The slim seven-pin design provides optimal space savings for PCB and wired connections within the power shelf and offers easy configurability to meet various voltage and current ratings. Amphenol’s overmolded AC Whip cables meet both IEC and NEMA cable industry standards and offer a best-in-class solution for modular rack architectures.

Amphenol’s OCP-compliant AC Input Connectors and Cable Assemblies are designed to meet OCP’s V3 Universal Input power distribution architecture standards and provide a convenient method of routing power directly from the busway to the power shelf within the V3 rack. The slim seven-pin design provides optimal space savings for PCB and wired connections within the power shelf and offers easy configurability to meet various voltage and current ratings. Amphenol’s overmolded AC Whip cables meet both IEC and NEMA cable industry standards and offer a best-in-class solution for modular rack architectures.

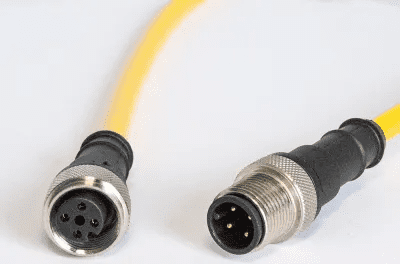

RS supplies HARTING M12 A-Code cable assemblies. Product features include compact overmold design, IP67 protection, and shock and vibration resistance. Product is available in three cable jacket materials: PVC, PUR, and TPE. An anti-rotation coupling nut guarantees secure locking with the receptacle. All assemblies are available in standard lengths and custom length per request. Assemblies can be provided in various configurations such as single-ended with open unterminated end and double-ended with an overmolded connector on each end. All connectors come with 3-, 4-, or 5-pin configuration.

RS supplies HARTING M12 A-Code cable assemblies. Product features include compact overmold design, IP67 protection, and shock and vibration resistance. Product is available in three cable jacket materials: PVC, PUR, and TPE. An anti-rotation coupling nut guarantees secure locking with the receptacle. All assemblies are available in standard lengths and custom length per request. Assemblies can be provided in various configurations such as single-ended with open unterminated end and double-ended with an overmolded connector on each end. All connectors come with 3-, 4-, or 5-pin configuration.

![]() The silicone overmolds from the Fischer Core Series from Fischer Connectors in sizes 104 and 105 are medical cable assemblies tested to ISO 13485. Fischer Connectors’ wide range of silicone cable assemblies includes custom silicone overmolds, custom geometries, and low-friction coating to prevent damage over the lifetime of the cable. Custom colors are available. Overmolds and heat-shrink tubing that provide sealing at the junction of the connector and the cable can impart functionality such as abrasion and impact resistance, low friction, vibration damping and protection from fluid ingress. One of the insulation materials available in rubber is silicone. It’s generally non-reactive, stable, resistant to extreme environments, and offers the widest thermal range (from -60 °C to 180 °C). Silicone cable assemblies thus stand up to any sterilization challenge you can throw at them: steam autoclave, high heat, disinfectants, and sterilant solutions.

The silicone overmolds from the Fischer Core Series from Fischer Connectors in sizes 104 and 105 are medical cable assemblies tested to ISO 13485. Fischer Connectors’ wide range of silicone cable assemblies includes custom silicone overmolds, custom geometries, and low-friction coating to prevent damage over the lifetime of the cable. Custom colors are available. Overmolds and heat-shrink tubing that provide sealing at the junction of the connector and the cable can impart functionality such as abrasion and impact resistance, low friction, vibration damping and protection from fluid ingress. One of the insulation materials available in rubber is silicone. It’s generally non-reactive, stable, resistant to extreme environments, and offers the widest thermal range (from -60 °C to 180 °C). Silicone cable assemblies thus stand up to any sterilization challenge you can throw at them: steam autoclave, high heat, disinfectants, and sterilant solutions.

Amphenol Pcd offers high performance injection-molded cable assemblies, supporting Amphenol’s 2M Connector Series. With superior cable overmolding capabilities, the 2M Series is available as a drop-in replacement to competitors’ connectors. The unique combination of interconnect expertise and harness manufacturing capabilities enables Amphenol Pcd to offer the optimum solution at the design phase by leveraging its connectors and wire management and harness solutions, with the goal of reducing weight, installation, and maintenance times, as well as optimizing cost.

Amphenol Pcd offers high performance injection-molded cable assemblies, supporting Amphenol’s 2M Connector Series. With superior cable overmolding capabilities, the 2M Series is available as a drop-in replacement to competitors’ connectors. The unique combination of interconnect expertise and harness manufacturing capabilities enables Amphenol Pcd to offer the optimum solution at the design phase by leveraging its connectors and wire management and harness solutions, with the goal of reducing weight, installation, and maintenance times, as well as optimizing cost.

Powell Electronics offers Glenair overmolded cable assemblies, including overbraided, shielded, and caustic-chemical-resistant designs for harsh environmental interconnect wire harness and cable assembly applications. Overmolding is the preferred solution for environmental protection of military, aerospace, and harsh-environment industrial interconnect cable assemblies. Typical interconnect cable assemblies made for high performance applications — from fighter jets to dismounted soldier systems — have better overmolded cable and connector sealing materials, as well as better mechanical / bend protection, shielding from electromagnetic interference, superior wire termination strain-relief, higher IP levels of environmental sealing, and superior all-around durability performance compared to those used in consumer products.

Powell Electronics offers Glenair overmolded cable assemblies, including overbraided, shielded, and caustic-chemical-resistant designs for harsh environmental interconnect wire harness and cable assembly applications. Overmolding is the preferred solution for environmental protection of military, aerospace, and harsh-environment industrial interconnect cable assemblies. Typical interconnect cable assemblies made for high performance applications — from fighter jets to dismounted soldier systems — have better overmolded cable and connector sealing materials, as well as better mechanical / bend protection, shielding from electromagnetic interference, superior wire termination strain-relief, higher IP levels of environmental sealing, and superior all-around durability performance compared to those used in consumer products.

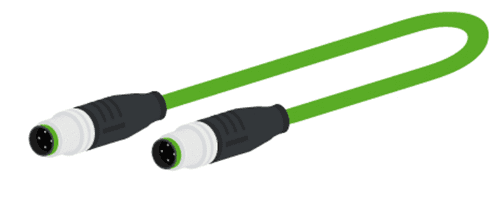

JPC’s overmolded M12 to M12 connectors are commonly used in harsh industrial environments where the connectors are subjected to vibration, shock, moisture, or other environmental stresses. JPC’s overmolding process helps to protect the connectors from damage and ensure reliable and consistent performance over time. JPC offers overmolded M12 harnesses in A, D, and X code as well as male or female plug options that come in either 4 or 8 pin configurations. Available in CAT5e or CAT6, we have standard PVC, LSZH jackets and CMX cable jacket options for outdoor conditions. These M12 assemblies are capable of up to 10 million flex cycles and are waterproof up to an IP67 rating. Our cables are Profinet, profibus, EtherCAT, and DeviceNet communication compatible, and are also RoHS compliant, air pressure, and FLUKE tested.

JPC’s overmolded M12 to M12 connectors are commonly used in harsh industrial environments where the connectors are subjected to vibration, shock, moisture, or other environmental stresses. JPC’s overmolding process helps to protect the connectors from damage and ensure reliable and consistent performance over time. JPC offers overmolded M12 harnesses in A, D, and X code as well as male or female plug options that come in either 4 or 8 pin configurations. Available in CAT5e or CAT6, we have standard PVC, LSZH jackets and CMX cable jacket options for outdoor conditions. These M12 assemblies are capable of up to 10 million flex cycles and are waterproof up to an IP67 rating. Our cables are Profinet, profibus, EtherCAT, and DeviceNet communication compatible, and are also RoHS compliant, air pressure, and FLUKE tested.

Phoenix Contact’s M8, M12, and MINI 7/8” form factors have become an industry standard for robust and watertight quick-connect applications. Used primarily on sensors, actuators, instruments, and devices, these circulars are now an essential component on most industrial machines. M8 and M12 stocked product is made with 105 °C yellow PVC. M8 products are ideal for areas with space constraints or devices with the smaller M8 interconnect. The cable is sunlight resistant and is offered in both shielded and non-shielded variants. M12s with 18 or 22 AWG wires are PLTC (Power Limited Tray Cable) rated, which allows easier cable routing according to NEC guidelines. Configurable cables are now available in black and gray PVC.

Phoenix Contact’s M8, M12, and MINI 7/8” form factors have become an industry standard for robust and watertight quick-connect applications. Used primarily on sensors, actuators, instruments, and devices, these circulars are now an essential component on most industrial machines. M8 and M12 stocked product is made with 105 °C yellow PVC. M8 products are ideal for areas with space constraints or devices with the smaller M8 interconnect. The cable is sunlight resistant and is offered in both shielded and non-shielded variants. M12s with 18 or 22 AWG wires are PLTC (Power Limited Tray Cable) rated, which allows easier cable routing according to NEC guidelines. Configurable cables are now available in black and gray PVC.

Binder’s overmolded M12-A is in accordance with FDA 21 CFR. It comes with stainless steel locking rings, protection degree IP69K, 3 to 12 pin variations, and an attractive grey design. The overmolded M12-A can be used for applications in the field of food and pharmaceuticals well as chemical industry.

Binder’s overmolded M12-A is in accordance with FDA 21 CFR. It comes with stainless steel locking rings, protection degree IP69K, 3 to 12 pin variations, and an attractive grey design. The overmolded M12-A can be used for applications in the field of food and pharmaceuticals well as chemical industry.

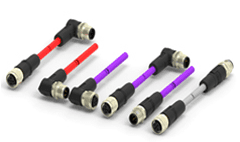

TTI supplies TE Connectivity’s A- and B-coded M12 cable assemblies. These cable assemblies comply with Profibus, DeviceNet, and CC-link protocols, offering multiple options for a variety of needs. They have 360° shielding against EMI for complete protection for signal and data transmission, and are rated IP67 for resistance to dust and water. The assemblies are overmolded in either PVC or halogen-free polyurethane (PUR) cables, suitable for drag chain applications, or torsional stress, depending on customer performance requirements.

TTI supplies TE Connectivity’s A- and B-coded M12 cable assemblies. These cable assemblies comply with Profibus, DeviceNet, and CC-link protocols, offering multiple options for a variety of needs. They have 360° shielding against EMI for complete protection for signal and data transmission, and are rated IP67 for resistance to dust and water. The assemblies are overmolded in either PVC or halogen-free polyurethane (PUR) cables, suitable for drag chain applications, or torsional stress, depending on customer performance requirements.

KYOCERA AVX has been producing custom automotive connectors for over 20 years. Core to its technical and performance advantages are its proven contact technologies and innovative manufacturing capabilities. Combined, KYOCERA AVX’s custom capabilities, including overmolded lead frames, manufacture some of the most complex and leading edge automotive connectors available today.

KYOCERA AVX has been producing custom automotive connectors for over 20 years. Core to its technical and performance advantages are its proven contact technologies and innovative manufacturing capabilities. Combined, KYOCERA AVX’s custom capabilities, including overmolded lead frames, manufacture some of the most complex and leading edge automotive connectors available today.

Learn more about cable assemblies.

Wire & Cable Assemblies for High-Temp Applications Product Roundup

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Fischer Connectors, HARTING, Harwin, LEMO Connectors, and PEI Genesis.

Like this article? Check out our other Product Roundup, Product News, and Connector Industry News features and our 2023 and 2022 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024