LED Car Exterior & Interior Lights – Adoption Accelerates in Automotive Industry

Automakers are moving away from incandescent bulbs at increased speeds, eliminating a longstanding connector market. Opportunities for interconnect suppliers to shift gears and merge into more advanced automotive LED lighting applications abound.

LEDs give lighting designers new opportunities to create distinctive lights.

Much of the automotive industry’s attention is focused on the requirements of safety systems and autonomous driving, but there’s a similar revolution happening in vehicle lighting. The transition to LEDs is racing right along, driven by declines in the cost of LEDs. LEDs are a vastly different technology than incandescent bulbs, and they are significantly changing interior and exterior automotive designs. Now these changes are rippling out to connector suppliers.

As incandescent lightbulbs disappear, the demand for compatible connectors will also fade. This shift is forcing component suppliers to focus on solid-state lighting systems. Adaptive front lighting and emergency brake lights are among the driving forces creating new opportunities for connector suppliers. Stylists are also putting more LEDs around the vehicle, creating markets for a range of different connectors and LED holders. However, LEDs aren’t expected to completely take over. There’s still a solid market for xenon and halogen bulbs in the automotive realm.

In the short term, most automotive LED growth will be driven by conventional vehicles, but design teams are keeping a steady eye on autonomous cars. Most of the design changes arising to capitalize on the benefits of driverless cars will occur in vehicle interiors, as removing human driving requirements provides the freedom for all passengers to seek personal comfort, such as communal seating and enhanced entertainment options. Some of these new designs will also appear in conventional vehicles first.

“Drivers increasingly want the option to adjust lighting to their requirements, for example, to create an individual, feel-good atmosphere,” said John Kuijpers, head of the car body and interior lighting business at Hella. “The trend towards autonomous driving creates new challenges for interior lighting. When people no longer need to drive themselves, the rigid seating positions are broken up and comfort enters into focus.”

Audi’s A7

Audi, one of the first automotive suppliers to move LEDs into production, continues to push technology in its new A7 Sportback, which uses interior and exterior lighting designed in partnership with Hella, a German lighting supplier. The partners pushed the envelope for interior lighting, using second-generation red-green-blue LEDs that are managed by an overhead control unit designed to handle interior lighting, moonroof positioning, sensors for passenger compartment monitoring, and a microphone. Another lighting highlight is the Matrix LED reading light, which integrates seven individually controllable LEDs in the ceiling to provide optimal illumination for any seat. Passengers can set brightness and choose from more than 30 colors to create an individual color profile.

Hella and Audi designed a new cabin light that lets passengers illuminate specific areas.

Exterior automotive lighting is undergoing an even greater change. White LEDs in forward lighting are merging into the mainstream as prices fall, giving lighting stylists freer rein to innovate while also letting engineers create the illusion of motion. Signal lights can push observers’ attention towards the direction a vehicle is turning, and it turns, side-facing LEDs can illuminate to further indicate its sideways trajectory.

Audi controls lighting and related modules with a single eight-channel control unit that runs 32 LEDs. The Hella-designed controller also integrates the front camera, sensors, and headlamps to provide glare-free high-beam functions, operates low-beam lamps, and uses multiple LEDs to create a wiping motion for turn indicators. Individual LED management lets the exterior lamps execute lighting sequences to greet drivers as they approach the car. A different display sequence is activated when they leave.

Philips Lumileds is also focusing on headlamps and recently unveiled a line that increases brightness by 160%. The Ultinon line employs Philips’s AirFlux heat-management system, which directs heat away from the light’s critical components, extending lifetimes to eight years or well more than half the average lifetime of a car. Ultinon LEDs integrate controls directly into the body of the bulb so lamps take less space in the headlight unit and can be installed in a wider range of vehicle models.

Many connector companies are designing products for this new generation of headlamps. ERNI Electronics says that connectors used in headlight applications must be vibration-resistant with reliable locking features to withstand the realities of the road and must be able to handle heat, both from operating in a warm environment and handling high currents. Package size is also an important consideration: ERNI’s connectors come in increments of 1.27mm and 2.54mm to save space. ERNI also emphasizes ease of use and safety features to protect the person plugging the lamp in.

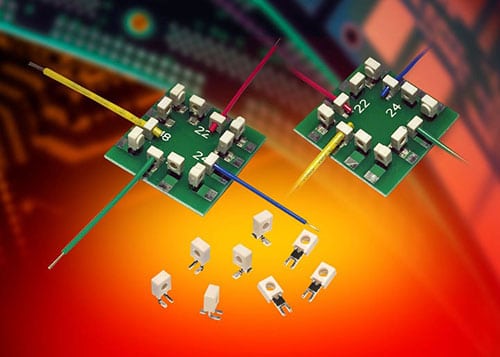

AVX’s 9176-600 Series single-tine, plated through-hole IDCs.

That usability factor is also an important aspect of ITT Cannon’s CTC Series environmentally sealed connectors, which enable users to install them by hand without any special tools, making repairs fast and easy. They also ensure reliability with up to IP69K sealing and a positive locking latch.

AVX Interconnect offers a variety of IDC and poke home wire-to-board (WTB) connectors that support LED applications in the automotive environment as well. Its 9176 family of IDC connectors offers low-cost, WTB connector solutions, including the first plated through-hole option designed to serve this market, which is available in either an end or through-wire configuration.

Osram’s XLS fog lights can be used in all standard signaling applications.

The proliferation of individually controlled LEDs is eliciting major design challenges, as suppliers and OEMs have largely operated on their own, creating a number of different interconnection schemes. Osram is tackling this issue with standardized LEDs for signal lights. The XLS (eXchangable LED Signal) combines standardized light sources and LED technology, with standardized lamps in yellow, white, and red for different signal applications.

“A uniform platform with four different light sources can cover all the important signal applications in vehicles,” said Hans-Joachim Schwabe, CEO Specialty Lighting at Osram. “This allows simple replacements, reduces complexity and overall costs for car manufacturers, and leads to faster development processes, thanks to adapted standards.”

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024