Hyperboloid Contact Technology is Still Going Strong

From transportation to MIL/Aero to medical and more, hyperboloid contacts continue to be vital in the evolving world of electronics.

Francois Robert Bonhomme invented the hyperboloid contact in 1956 in response to the need for more reliable connectors used in railway applications. By that time, rail systems had lighting and ventilation, but due to the high amount of shock and vibration that occurred in the train cars, the connections were not secure. This resulted in frequent interruptions of these services.

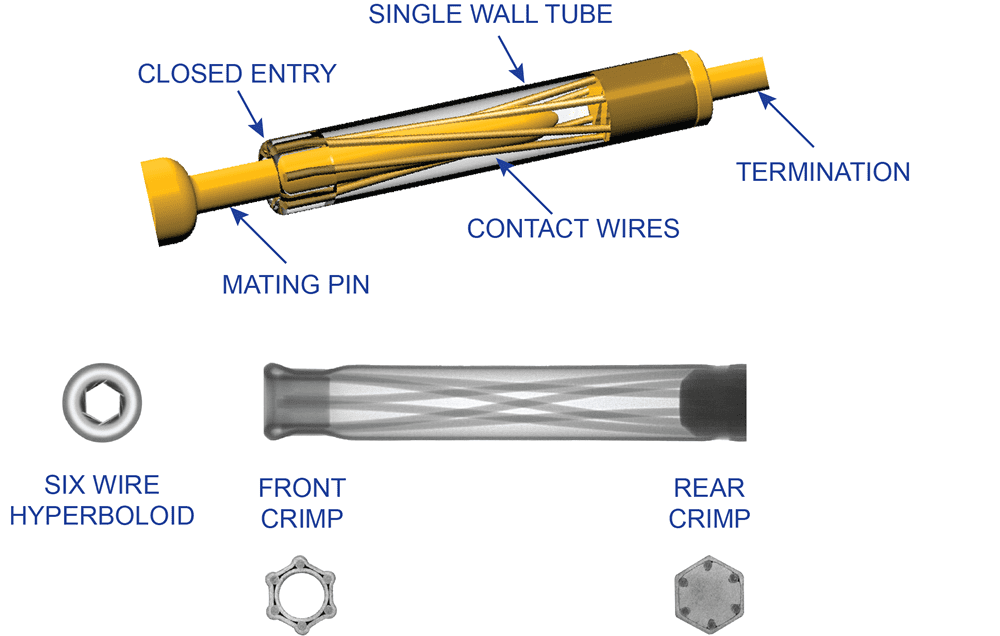

The connectors being used were simple stamped or machined contacts with a very small area of contact between the pin and the socket. “The bright idea was to create a contact with multiple connection points along the surface of the pin,” said Giuseppe Lancella, commercial director for the connector business unit at Smiths Interconnect. This was accomplished by creating a wire cage in a hyperboloid shape that wrapped around the pin when the connection was made. With multiple points of contact, the connection remained continuous even if some of the wires briefly lost contact due to shock and vibration.

Development of the technology continued in France into the 1960s and was eventually patented. The patent was offered to companies in other countries, expanding its use in new markets and applications impacted by shock and vibration, such as military and aerospace. Lancella explained that high-speed signals increased the use of sophisticated technology on fighting vehicles, such as helicopters, that needed to limit signal interruption to less than a microsecond, and eventually to less than a nanosecond, in the face of increasing vibration. This led to the success of hyperboloid technology in the defense market.

Low insertion force, high mating cycles

Another important characteristic of hyperboloid contacts is their low insertion force. Insertion force is a factor in applications that require high pin counts, or when the pins are larger in size.

High insertion force makes it difficult to physically make the connection and can lead to excessive wear and shorter life in applications that require high mating cycles, such as Test & Measurement. Improvements to the hyperboloid technology made it possible to easily reach 100,000 mating cycles without degradation, and without an increase in the current resistance of the contact. “The low insertion force became extremely important with the increasing density of the connectors,” said Lancella.

Smiths Interconnect’s Hypertac hyperboloid is the original superior performing contact technology for use in demanding environments where reliability and safety are critical. The shape of the contact sleeve is formed by hyperbolically arranged contact wires, which align themselves elastically as contact lines around the pin, providing a number of linear contact paths.

More and more connector applications require a high number of contacts, without increasing the size of the connector, or changing its ergonomics or functionality. Although in many electronic applications, space availability is decreasing, density is increasing. Higher density increases the force needed to mate the contacts. Hyperboloid contacts offer a huge advantage because they allow a smaller and lighter connector design. “For example, if you have a 300 position connector, and each contact is six ounces, that’s 1,800 ounces (112 lbs) of force, which is a substantial load to mate the connector. If that can be reduced to approximately two ounces per contact, you have reduced the force to engage the connector by two-thirds,” said Paul Gurrisi, engineering manager at QA Technology Company.

Design model and X-ray of QA Technology’s integraMate ICS series. QA manufactures and supplies hyperboloid contacts to the companies that make connectors. Its products offer the advantages of lower mating force and a smaller diameter than other contacts on the market.

“No one likes the idea of a connector that becomes a two-handed operation because the mating force is so great, or where the nice crisp click of the latch can’t be heard (or even felt) because so much force was required to mate the connector,” wrote Robert Lascelles, retired product manager-integraMate at QA Technology Company.

In addition to reducing the size of the connector, hyperboloid contacts can reduce the number of connectors required, by increasing the number of contacts. “Where there were two connectors on the interface on the front of the instrument, there can now be one. Because the insertion force is low enough, by adding the extra contacts to that one connector, it can still be connected without excessive force,” said Jeff Brown, product design engineer at QA Technology. “Our design approach offers a smaller outside diameter for a given pin size and closer center spacing. This allows higher pin counts in the same given area.”

Hyperboloid contacts allow the connector to remain out in the field for longer than a stamped contact. Some common medical connectors are rated for about 5,000 cycles, but with hyperboloid contacts rated for 100,000 cycles the significant advantage is that it lasts that much longer without needing to be replaced or repaired. This saves money overall, despite paying a little more for them compared to stamped or screw machine contacts.

By their unique design, hyperboloid contacts are resistant to fretting (micro motion) and corrosion. When a connector with stamped or screw machine contacts is subjected to vibration the gold plating can wear out, even though there may not be discontinuity. “That micro vibration can wear the gold and also wear out the connector, even without a high number of insertions. Whereas hyperboloid contacts, because they have that long line of contact on each of the individual wires without a lot of force, they are less susceptible to fretting wear,” said Jeff Smith, director of global sales at QA Technology.

Hyperboloid technology is often used in medical equipment, specifically with single use disposable devices that are frequently changed out, for example, catheters. “You can keep changing the disposable part and achieve more cycles out of the connection,” said Brown. “In an ER application where you have multiple patients a day and you have a disposable item being plugged into the equipment, you need that long life. Otherwise, your equipment will need servicing or replacing much sooner.”

Customization and prototyping

Hyperboloid contacts allow for changes in some parameters. “With a smaller pin diameter, less wires are needed. If you need a bigger pin to carry more current, you can increase the number of wires. You can also adjust the diameter of the wire. You can have a smaller wire with a small contact, or a bigger wire if you need more current rating. You can change the inclination of the wire for more or less insertion force. If you have a sharper wire angle, you will increase the level of insertion force. Some engineers don’t need such a low insertion force and instead want to have a better retention of the contact. The hyperboloid shape offers a lot of options in the construction of the contact for different levels of performance,” said Lancella. In addition, he said, cost can be optimized with selective plating. “The construction around the wire can be, for example, nickel plated, to save money.”

Another area for cost savings, explained Lancella, is at the beginning of development. Small quantities of contacts can be produced with very limited investment because only the wire is needed to build the components, compared to stamped contacts that require tooling, which can be quite expensive.

In the era of smaller, lighter, faster connectors, hyperboloid contacts play a significant role by reducing contact density, lowering insertion force, and increasing mating cycles.

To learn more about hyperboloid contact technology, see our Meet the Connector article on the topic.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Smiths Interconnect and QA Technology Company Inc.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024