High-Density MT-Based Optical Solution Brings Big Bandwidth Boost

A new high-density MT-based optical interconnect is coming soon. With up to four MT ferrules accommodating up to 96 optical channels, VITA 87 brings big bandwidth in a small footprint.

The addition of complex embedded systems to the next generation of multi-functional military equipment is driving a new wave of development in associated components. More speed, greater density, and higher levels of power are required to enable radar systems; sensor rich camera systems; unmanned and robotic systems; AI functions; Command, Control, Communications, Computers (C4ISR) systems; and a whole host of vehicles, surveillance and communication devices, weaponry, and avionics applications. Standards organizations and connector suppliers are working together to bring developers new interconnect options to serve the needs of external connections outside of boxes in high-performance systems where low weight, high speed, and ruggedness are key considerations. One highly anticipated product is a new high-density mechanical transfer (MT)-based optical connector designated as the preliminary VITA 87 standard.

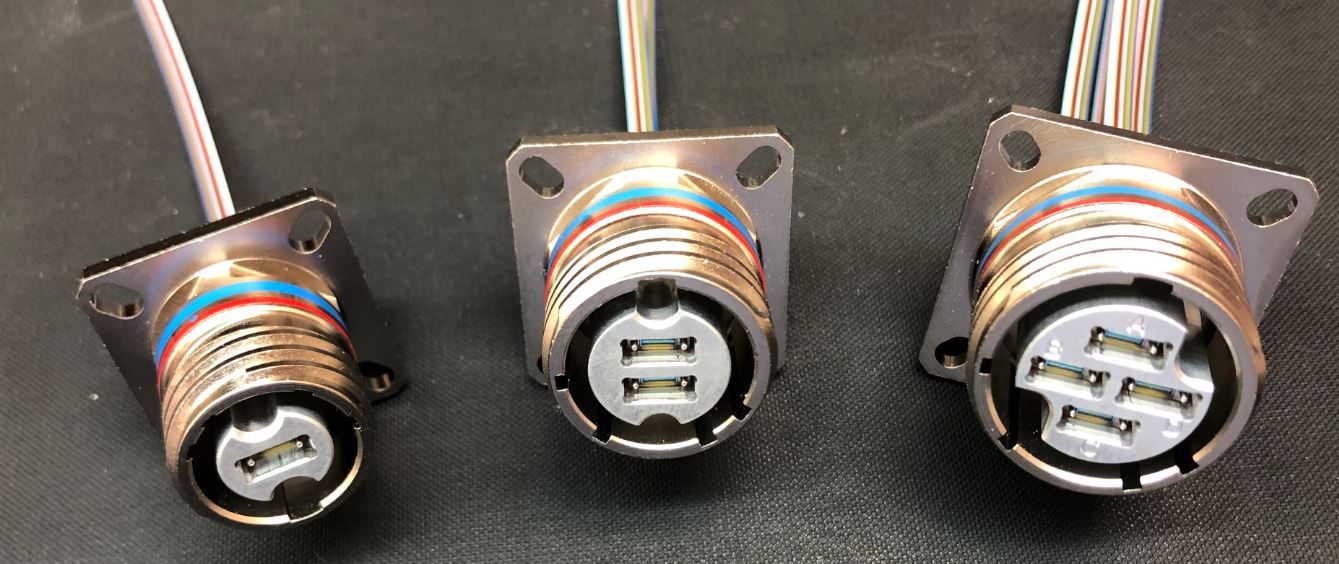

VITA 87 connectors in size 11, 13, and 15 receptacles

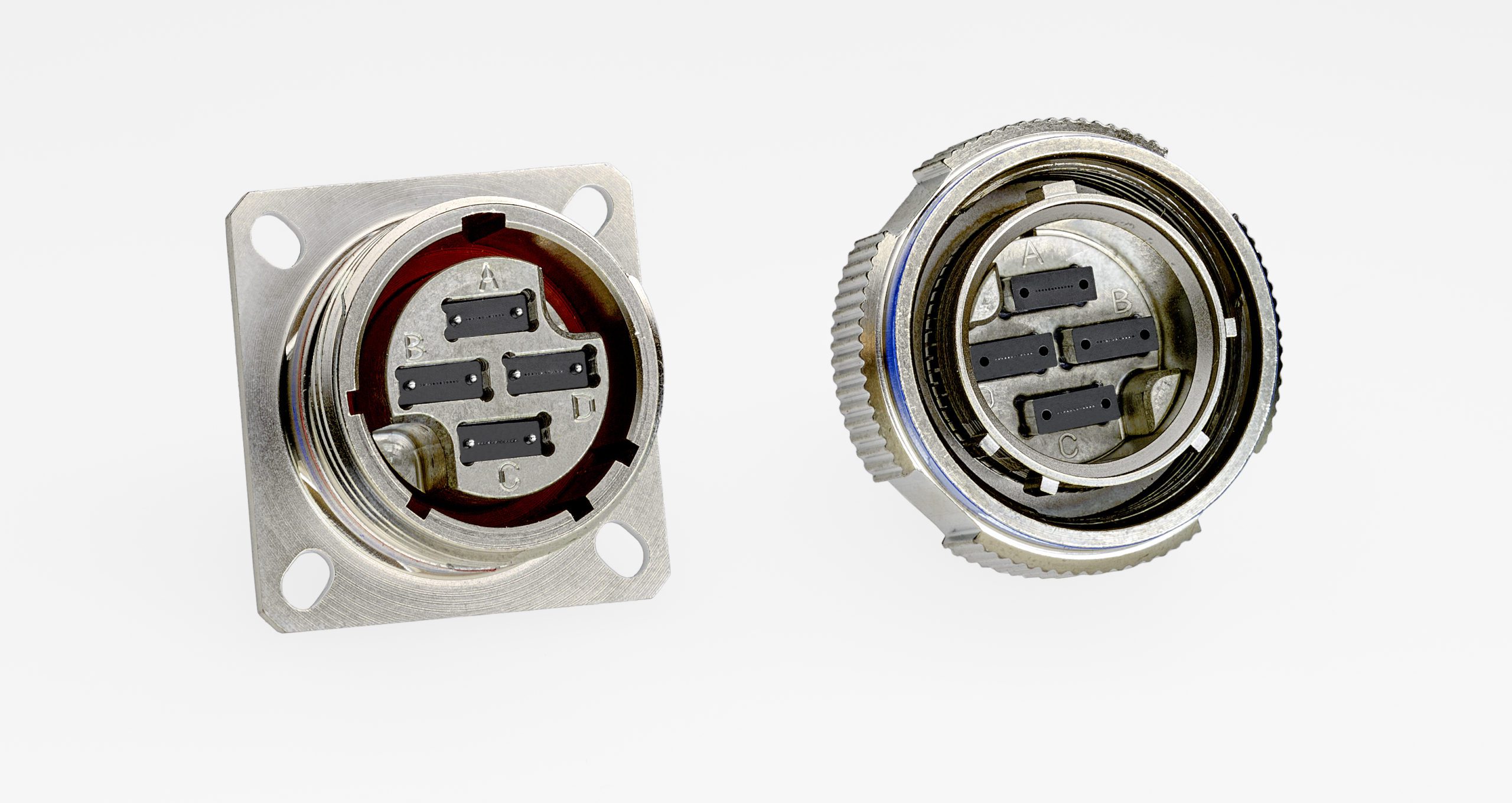

VITA 87 size 13 with a two-plug receptacle configuration

The VITA 87 connector is housed in a MIL-DTL-38999 Series III type shell (sizes 11, 13, and 15) and features 12 or 24 fibers on one, two, or four MT ferrules, respectively — with potential to increase in the future. A single connector could include up to 96 fibers. It is lightweight and available with physical contact MTs as well as a lensed fiber MT version. The standard configuration can be modified with keying and plating options. Future extensions to this product will see increased fiber counts. “This trend of density and high fiber counts is going to continue. We’re limited to 24 fibers today but higher count options, lensed and PC, are out there,” said Brent Hatfield, product manager – rugged fiber optics, at TE Connectivity (TE). The VITA 87 connector is expected to be in production in February 2022.

The VITA 87 working group, chaired and technically edited by TE Connectivity and including military vendors, developed this connector at the behest of the supplier’s customers. “Our customers were clamoring for it. This was largely driven by their need for a high-density product,” said Hatfield. “Land-based, ship, and airborne applications have taken a quantum leap in bandwidth needs, especially with the increased sensors and data explosions that accompanies sensors. In the last 18 months, we’ve seen the transceiver count going up, along with speeds increasing from 10 to 25 G and relying on existing solutions no longer made sense.”

The use of MT fibers in military and aerospace connectors, as well as those specified in data centers, telecom, and other high-speed systems, is increasing due to their ability to provide high-density interconnection in a format suitable for harsh environment applications. Optical cabling enables designers to streamline cabling content in areas that can quickly became crowded.

“We needed an optical solution to better meet the needed traffic density on the I/O panels. Legacy multiple MT ferrule connectors are too large to fit the available panel space and support the required fiber counts for the to the system I/O density,” said Mark Benton, Actives product manager at TE. The company’s history with HD fiber interconnects positioned it to leverage accumulated knowledge to engineer a higher density product.

“VITA 87 is not TE’s first connector development with multiple MT fiber connectors. We have a lot of internal expertise that we were able to use,” said Benton. “The connector needed to meet the expected performance and quality expectations while taking on new levels of capability in a restrained package format. It takes a lot of engineering know-how to make this complexity manufacturable. There was a body of opinion that it was impossible to make, but here we are, and we aren’t done yet. The increased use of parallel mid-board transceivers has driven new capabilities in connectors that can support their potential. This connector enables designers to take advantage of current transceiver technology. We’ll get a little reprieve now, because the transceiver speeds are currently so high, but we’ll inevitably be coming back in the future with products that support the next level of transceiver speeds.”

Additionally, VITA 87’s obvious value to designs that include sensors means the new Sensor Open Systems Architecture (SOSA) standards will come into play. “There could be six or eight sensors on a drone, for example, and in that application low weight and high data rate are both crucial,” said Hatfield. “These connectors can manage non-optical control signals and Ethernet. They will have a lot of utility to designers working on small, high-capability equipment.”

ANSI standardization will be the next step. Once the VITA standardization process is complete, there will be open opportunity for other suppliers of MT connectors and ferrules, such as Glenair and Radiall, to produce the product. The VITA 87 connector pairs well with VITA 66 backplane solutions, which gives customers compatible options for inside-the-box backplane connectors.

A size 15 VITA 87 plug and receptacle with four ferrules

“We try to understand what the customer is trying to do on a system level and consider cost, performance, and operating environment to develop a standard that has the most capability, compatibility, and flexibility possible,” said Hatfield. “It is a strategic balance, but VITA 87 is the next step in the evolution.”

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024