From Phones to Wearables, Device Battery Connectors Deliver Secure Power

As more products go cordless, durability has become an imperative for battery connectors.

Batteries enable devices to operate using stored energy instead of a wired connection to an energy source. As more devices that once were wired become available in cordless versions for high-reliability purposes such as medical equipment or industrial equipment, the connectors that connect the battery or battery pack within the device must become more durable and more easily operable.

A few decades ago, battery connectors in consumer devices largely consisted of commercial assemblies made up of holders, clips, and simple spring or leaf-spring contacts. Today, consumers have access to powerful battery-powered devices such as cellphones, medical devices, and wearables — including those used in soldier-worn military equipment — that may have advanced computing capabilities and handle greater currents. The task of replacing or charging the battery may occur in challenging environments or be accomplished by inexperienced users. As a result, battery connectors have evolved to facilitate these requirements and support the overall durability and performance of the device.

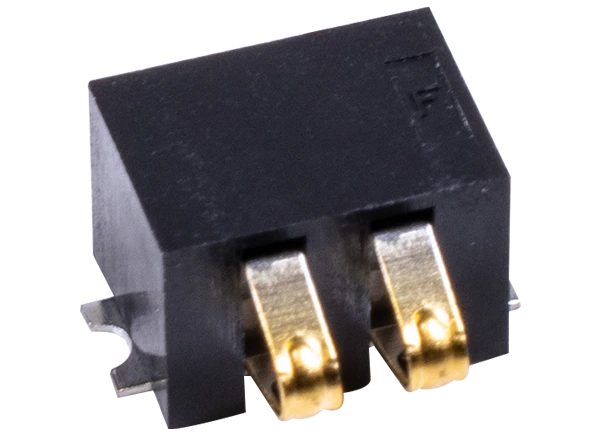

KYOCERA AVX 9155 Battery Connectors, available from Mouser Electronics, features both horizontal and vertical options. These robust KYOCERA AVX connectors are suited for board-to-board connections as well as battery pack integration in medical, commercial, and harsh environment applications.

“Many interconnects for batteries today have origins in the mobile phone industry. They are smaller and more robust because of that. They also handle higher levels of current,” said Giuseppe Rovitusa, business development manager for micro solutions at Molex. “A general trend impacting battery connectors is shrinking size. The combined volume of all the connectors used on the board can be as much as 50% of the available space in a device, depending on the number of modules. Shrinking those connectors allows the size of the battery to increase, which then extends the amount of time the device can operate on a charge.”

The miniaturization of connectors for use in the phone industry helped inspire innovation across other product categories and markets, as designers and OEMs availed themselves of these nano, micro, and mini connectors. The portable medical device market and military wearables in particular benefit from the arrival of miniaturized interconnects, and as those markets have developed exciting new applications, OEMs and device designers have pushed for even smaller connectors. Products like continuous glucose monitors (CGMs) and implantable devices require the tiniest of board-to-board connectors, yet due to the harsh environment requirements of medical wearables, they must also be rugged, waterproof, and long lasting.

Rovitusa says that Molex, which produces a huge proportion of the battery connectors on the market, is continually improving its interconnects to serve its customers’ requirements. For example, a critical parameter for ensuring performance comes in the form of a proprietary alloy used in the contact design. This material improves contact resistance. “With board-to-board connectors, a key design parameter is to keep contact resistance as low as possible, or as close to zero milliohms as possible. Our newest products have a contact resistance in the low single digits of milliohms.”

Another design strategy that improves the ruggedness of battery connectors is to assemble them using insert molded manufacturing technology. “Traditionally, connectors have been assembled into their set positions on the manufacturing line,” said Rovitusa. When the contacts are inserted into pre-formed or drilled holes, the possibility is greater that they could become loose or damaged. “An alternate strategy is to inject the mold around the contacts. They are then fixed into place inside the resin. This provides greater strength.”

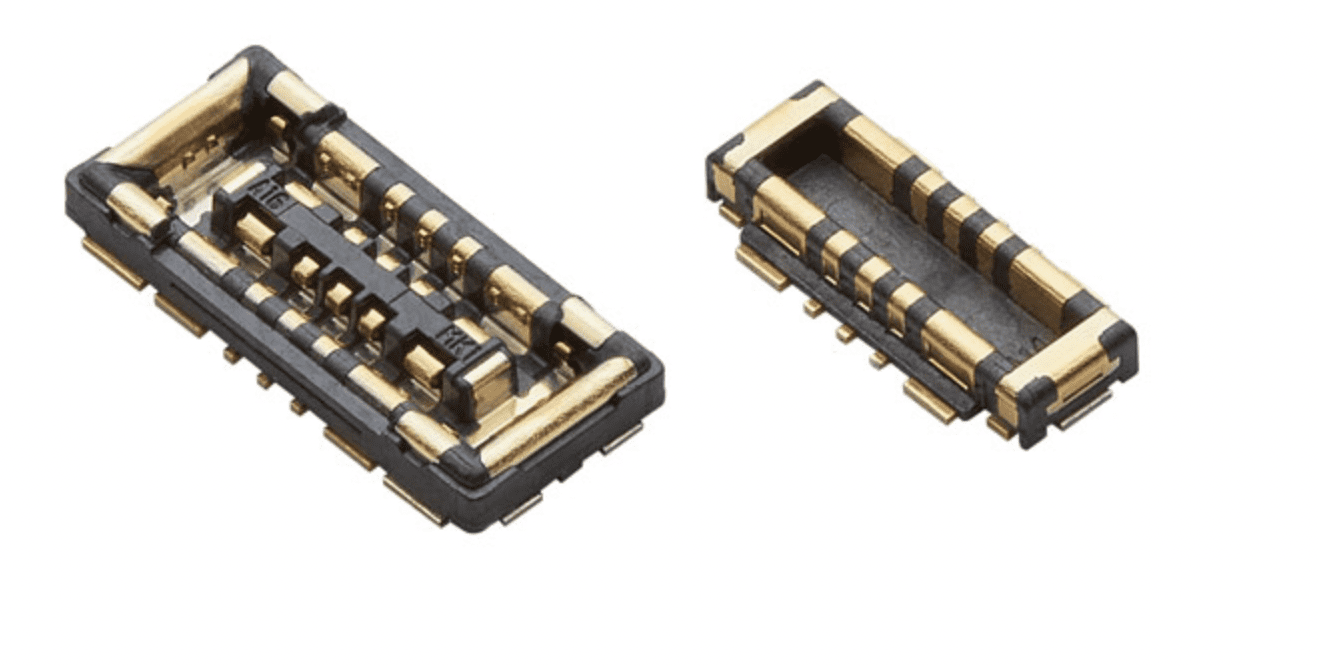

Molex’s SlimStack Board-to-Board Hybrid Power Connectors GCB7 (0.35mm pitch) and New GCB7 (0.40mm pitch) also available from Mouser Electronics, achieve up to 15.0A of power and electrical reliability in an ultracompact design for battery and other power applications.

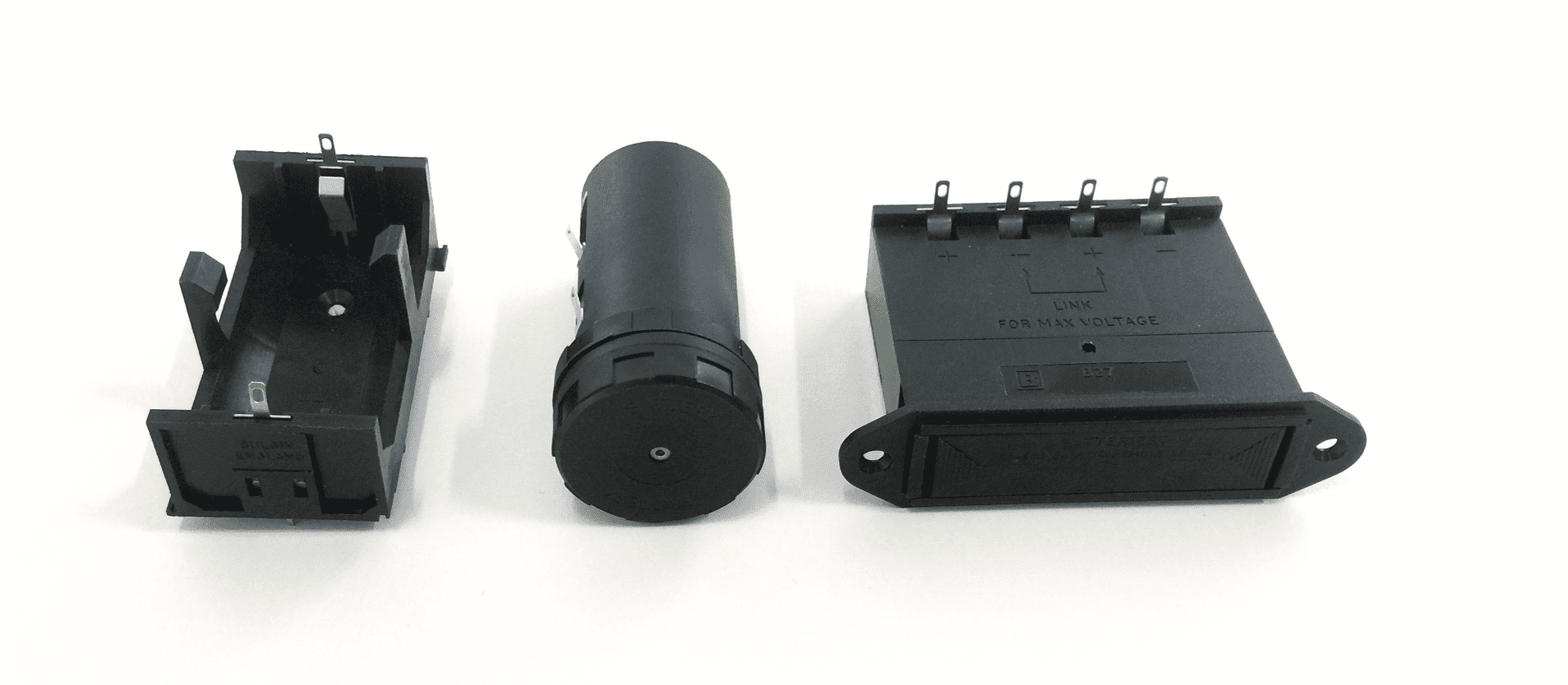

Some portable applications use a battery holder, a removable compartment in which batteries are inserted. The holder keeps battery cells fixed in place while conveying power from the batteries to the device, adding a layer of protection between the power source and the user. It also helps protect the battery and contacts from moisture or particulates in harsh environments. The battery holder typically has external connections made by contacts such as pins, surface mount feet, soldered lugs, or wire leads. The size and form of battery holders is determined by the battery type, size, and chemistry. The products that use these range from low-powered consumer goods to computing peripherals and memory backup.

Bulgin’s battery holder range, available from TLC Electronics, caters for battery sizes AAA(R03), AA(R6), C(R14), D(R20) and PP3(6R61), accommodating 1, 2, 3 or 4 cells.

Bulgin’s BX0023 Battery Holder has a removable loading drawer for the battery. The supplier offers a choice of fixing styles, including screw and flange panel fixing, PCB, and base mounting versions. The panel mounting versions include a front panel sealed to IP67, which enables it to serve harsh applications where dust or water would inhibit equipment operation.

Mouser Electronics offers KYOCERA AVX’s 9155-800 Vertical-Mate 2.0mm Pitch Connectors, which eliminate end-user damage when pluggable modules or packs are pressed vertically into a base unit. The unique contact design deflects cleanly and efficiently when a module or mating connector is pushed vertically into position.

The ability to store energy is a critical feature of portable, wearable, and carbon-friendly technologies. As batteries continue to scale down in size and scale up in power storage, designers will be able to create previously unimaginable new products that will improve our quality of life and our ability to move more freely through the world.

Like this article? Check out our other articles on Connector Basics, our Consumer Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024