What are RAST Connectors?

Meet the Connector: RAST Connectors

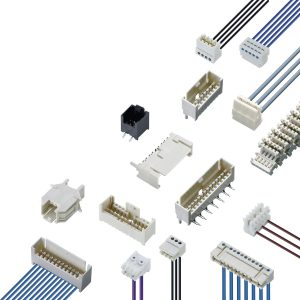

RAST connectors are an international standard originally developed for the home appliances market. The initial design featured a crimp-style contact, but today most iterations employ insulation displacement contact (IDC) technology, which simplifies the installation process, eliminates mis-mating errors, and improves connection quality by eliminating the need to cut, strip, and crimp individual wires. RAST connectors can be used as a direct mating system on the edge of a PCB, saving costs and installation space over crimp connectors and coordinating easily with other systems. Because the contacts are pre-assembled in the housing, there are fewer components to worry about and less chance of wires being inadvertently snapped into the wrong position.

The RAST standard was developed in the 1980s by a working group of European home appliance manufacturers, including Bosch, Miele, Siemens Hausgeräte, AEG (Electrolux), and Bauknecht (Whirlpool), joined by connector suppliers, including Lumberg, Molex, AMP (TE Connectivity), Stocko Contact GmbH, and Wieland Electric. The goal of the RAST development group was to eliminate incorrectly plugged connections and minimize incorrect wiring in the product assembly process. RAST also groups connections within the connector, avoiding the use of multiple individual connections and individual cable harnesses. Although the RAST standard originated with white goods, it has since been adopted for heating technologies and other industrial applications, as well as the automotive industry.

“More and more sub-assemblies in the automotive industry which are produced by Tier-1 suppliers must literally plug & play with a PCB in the final production process or the wiring system for the OEM,” said Lumberg’s managing director Ulrich Schmidt. “In addition, high flame-retardant qualities, originally designed for unattended household appliances, are met with growing interest by the automotive segment.”

RAST stands for Raster Anschluss Steck Technik in German, or “grid connection plug technology.”

Lumberg’s RAST 2.5 Series 35 features direct and indirect mating for cable-to-board and cable-to-cable connections in insulation displacement technology. For signal and low load currents up to 4 A, pitch 2.5 mm and 5.0 mm, RAST 2.5 Power offers signal and load currents 10 A, pitch 5.0 mm.

Design Notes

- Standardization: ZVEI, the Central Association of the Electrical Engineering and Electronics Industry (Zentralverband Elektrotechnik- und Elektronikindustrie) oversaw the development of the RAST connector system and finalized the standard in 1986. The standard is internationally used but has been adopted more slowly in the North American markets.

- Numbering: RAST connectors typically include a number in their designation that corresponds with the contact pitch; a RAST 5 connector has a 5 mm pitch, a RAST 2.5 connector has a 2.5 pitch.

- Voltages: RAST 5 connectors with a 5 mm pitch are designed to handle currents up to 16 A. 2.5 mm pitch connectors, on the other hand, can relay signal and small load currents of up to 4 A.

- Sizing: The larger RAST 5 connector is falling out of favor compared to the smaller, lighter RAST 2.5 connector, especially for applications such as EVs where size and weight reductions are critical. One solution: The RAST 2.5 plugs have open contacts next to one another, while the contacts on the RAST 5 plug are separated in individual, closed chambers. To send higher voltages via the RAST 2.5 connector, it is possible to assemble in every second grid step, essentially making a RAST 2.5 connector a 5 mm connector.

- Orientations: RAST connectors are available with mating headers in vertical and right-angle versions.

- Mounting options: In addition to through-hole PCB-mount products, many European manufacturers also offer surface-mount RAST connectors.

- Keying: RAST connectors are typically white, although suppliers may offer them in colors for easy identification in complex wiring architectures. A staggered footprint enables polarization on the PCB. They are available with polarizing ribs, side latches, and pip locks, in addition to open or slotted sidewalls on the 2.5 and Power connectors.

- Mating: Mates directly with PCB or via headers.

- Assembly: RAST connectors are suitable for manual or automated production methods. Connectors may be assembled on the board by lead-free reflow soldering, reducing assembly time.

- Cable considerations: Rather than use individual connectors and harnesses, RAST provides the ability to gang up connections, reducing the number of harnesses. Ribbon-type cable can be used with some products.

- Other certifications: RoHS, Glow-wire, UL, CSA, and VDE approved

Greenconn’s RAST Connectors are glow-wire-compatible and ideal for a variety of home appliance and automotive lighting applications. These connectors also offer various options for customization, such as locking mechanisms, position and keying systems, and color coding.

Markets, Sectors, and Applications

Consumer, Automotive, Industrial markets

White goods (washing machines and dryers, refrigerators and freezers, dishwashers and stoves, and small appliances); HVAC systems; EV and automotive systems (cabin lighting, headlights, sensors). RAST connectors are widely used in sensor, switch, actuator, and motor control lines that can be connected directly or indirectly with the PCB or components.

Molex’s RAST Connector System is UL-94V0-rated, Glow-Wire-compatible and delivers a range of current ratings to offer design flexibility for a variety of home appliance and automotive lighting applications.

Suppliers

Greenconn, Lumberg, Molex, TE Connectivity, JST, Wieland Electric

Related products:

- IDC Connectors

- PCB Edge-Mount Connectors

Like this article? Check out our other Meet the Connector and our Consumer Industry Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024