Custom Connectors Advance SWaP Goals for Hi-Rel Electronics

The size, weight, and power (SWaP) initiative has helped connector manufacturers focus on improving smaller and lighter connectors. Custom designs help make these goals achievable.

Modern electronic design dictates that our circuits do more in smaller packages but we still need reliable power and signal transfer. The military and aerospace sector has been particularly influential; its continual efforts to reduce equipment payloads (and fuel costs) and soldier-carried weight has led to reductions in form factors without performance loss. Every other market has adopted these design changes, and new configuration tools and customizable Interconnects have helped engineers stay ahead of a rapidly changing electronics industry.

Custom power handling capabilities

Customized connectors can be designed to include sets of 3A and/or 5A power lines adjacent to micro and nano signal lines to meet SWaP expectations. These devices offer smaller, lighter weight interconnect systems with a mixed variety of signal and power levels that still perform well in rugged and extreme environments.

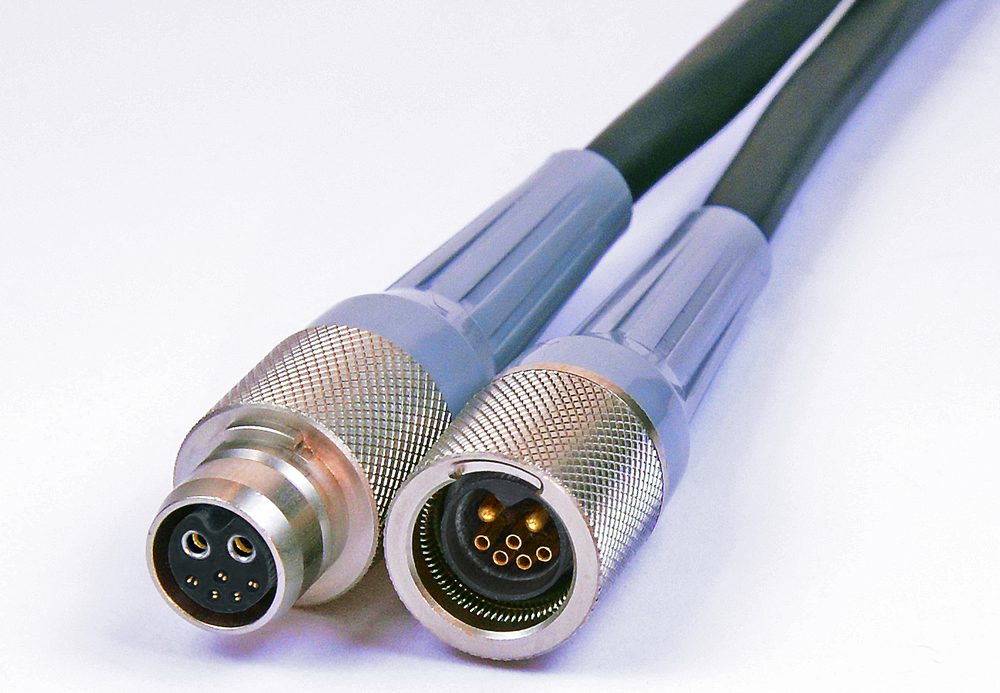

Hybrid circular connectors from Omnetics Connector Corporation have been configured with shielding and no outgassing for use in space.

For example, custom connectors that include combinations of USB 3.0 digital circuit speeds and are simultaneously running power sources that use 5A currents are ideal for highly portable military and airborne equipment. By adding power pins inside the same connector with signal pins, the designer reduces the number of cable and connectors running to and from the electronic module. This is essential in new space and remote-controlled drones as well as portable systems used by ground troops. The number of signal pins and power pins will vary from application to application and each design may be unique unto itself.

The good news: New configurator tools can reduce both cost and time to design these new mixed signal connectors. Custom is no longer a bad word in the application-specific connector world.

Designing custom connectors is easier

Updated design tools that use solid models can speed up concept drawing and provide the system engineer a visual and size specification in a matter of days. Connector designers have a broad family of commercial-off-the shelf (COTS) and standard designs already available from which to hinge changes. Often a standard connector can be changed into a custom application quickly with the use of an alternate insulator. Some suppliers stock solid insulator plugs and can machine first-article connectors to hurry the design to completion.

Costs are significantly lower than with the older methods of full-custom design. When a new connector metal shell system is needed, the supplier can use automated CNC machines to rapidly cut early prototypes directly from data received from the solid modeling software.

A custom cable harness by Omnetics takes into account every element of the interconnect assembly.

Custom power and SWaP connectors

Established micro and nano connector manufacturers that have offered military specification 32139 and 83513 now offer a wide range of design variations on these existing products. Both miniature rectangular and circular formats are readily available.

Custom power D-shaped micro connectors at .050mil spacing, a popular design for new applications, evolved from established standard D-shaped connectors. Omnetics’ high-reliability micro-D connectors are a good example and are available with mixed power/signal contact layouts. The number of power and signal contacts may be specified to provide the greatest flexibility in circuit design while ensuring that the connector is kept to the absolute minimum necessary size.

This hybrid combination eliminates the need to have a D-sub type or other higher-power connector next to the micro-D, making it easier for the operator who now only needs to mate a single connector. The power contact can handle 20 to 24AWG wire and is suitable for currents of 7A to 10A. These hybrid connectors can be available in wired or through-hole PCB-mount termination types. The wired power contact is an insertable/removable type contact, which can be optionally supplied for customer termination, except for through-hole leads that are permanently installed. These options can be packaged in the conventional screw-together-type micro-D shells or the Omnetics quick-latching micro-D form factor.

Micro and nano circular connectors optimized for SWaP.

Custom miniature connectors with mixed power and high-performance signal contacts have come of age. The move away from older standard designs has been empowered by the use of new tools and solid model designs that enable designers to package highly established standard pin-and-socket elements into new interconnect solutions that fit the specific needs of an application. Working with a supplier that has expertise in SWaP products can help achieve custom solutions that have the high reliability of experienced standard products. By specifying military-grade materials, internal elements, and design standards, these custom products achieve SWaP goals and deliver performance.

To learn more about optimizing interconnects for SWaP, visit Omnetics Connector Corp.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Custom Connectors Advance SWaP Goals for Hi-Rel Electronics - March 28, 2023