Automated Vehicles Drive Change in Warehouse Work

Efforts to improve automotive safety are trickling down to the smallest vehicles, including those that never hit the roads.

Automated Vehicles

The quest to develop safer cars is also influencing the design of smaller vehicles, benefitting manufacturing companies, warehouses, and the people who work in them. A new generation of autonomous guided vehicles (AGVs), also called autonomous mobile robots (AMRs), are essential to efforts to improve efficiency in manufacturing and warehouse distribution. New AGVs rely on autonomous technologies and sensors to guide robots that carry materials around factories.

Honeywell is partnering with Fetch to help its customers adopt autonomous mobile robots.

As online purchasing revolutionizes retailing, AGVs and AMRs are taking over many roles in the supply chain. Mass and e-commerce retailers such as Walmart, Target, and Kohl’s increasingly rely on these machines to move through their vast warehouses. Amazon may be the largest user, with over 45,000 robots in operation in over 320 warehouses throughout the US.

Equipment suppliers are moving quickly to gain market share. In October, Honeywell teamed up with Fetch Robotics to provide AMRs aimed primarily at distribution centers that fulfill e-commerce orders. “As staffing challenges and the continued growth of online shopping are pressuring supply chains, robotics can be an effective solution to help make large, integrated distribution centers more efficient,” said Pieter Krynauw, president of Honeywell Intelligrated.

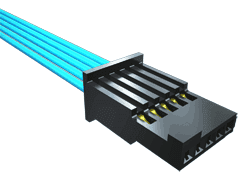

Compact connectors trim size, which is a critical factor in mobile robot design. (Photo courtesy of Molex)

A recent survey from the Material Handling Institute showed that members expect adoption to rise from 34 to 73% over the next five years, with more than half of the respondents saying that driverless vehicles have the potential to create competitive advantages. Adoption is currently at 11%, but half the respondents expect to adopt them within the next five years.

Cameras, along with LiDAR and radar, are driving this conversion to automation. Vehicles that use these technologies are more efficient and safer than robots that follow tracks or markings on the floor. As new demand for sensors comes from automakers and drone suppliers, sensor prices have declined across the board, making them accessible for companies that produce small vehicles.

High-speed connectors are needed to handle the high volumes of data created by sensors that guide vehicles that haul industrial goods. (Photo courtesy of TE Connectivity)

Seegrid, MiR, Locus Robotics, Fetch Robotics, GreyOrange, Swisslog, and Otto Motors are a few of the many young companies formed to address this burgeoning market. Most, including Fetch Robotics, use some combination of radar, LiDAR, and cameras developed for automotive safety and autonomy systems. Those sensors enable robots to navigate unpredictable warehouse environments safely and accurately, adjusting routes when obstacles get in the way.

Connector makers and sensor suppliers are expanding their markets by offering products that meet the needs of industrial transporters and cars. TE Connectivity’s High Speed Data Mate-ATX and compact 0.50 High-Speed Link lines are a few of its offerings for these sensor systems. A range of data connectivity modules can be configured for systems that don’t use conventional layouts.

Samtec offers a range of high-speed connector and cable assemblies for industrial and automotive applications. Its DW and SFSST lines are also suitable for mobile industrial robots, and its 75-Ohm HDBNC™ high-density BNC connectors substantially reduce the size of RF BNC components. Small size is also the focus of the Molex Mini50 Connection Systems line, which cuts the size of USCAR 0.64mm connectors by 50%, and its cost-competitive HSAutoLink interconnect system provides the high-speed performance required for high-resolution sensors.

Samtec offers many connectors, including the SFSST line, that meet mobile robot requirements.

These AMRs and AGVs also utilize high-power connectors to link battery packs to motors. Most of these connectors are for 100V systems or lower. That’s a marked difference from automotive power sources, which often go up to 300V.

Power requirements for robots that haul industrial package and equipment will vary depending on the weight of the payload. Many of the AMRs used in distribution centers run by Amazon, Walmart, and others carry 50 pounds or less. But some robotic vehicles carry hefty loads. Deutz, a diesel engine manufacturer based in Cologne, has about 50 AMRs carrying engines large enough to power large commercial trucks. The company previously used robots that followed a predetermined path. But vehicles with sensors can more easily avoid obstacles, including people. They are also easier to program.

It may be some time before autonomous vehicles hit the roads. But they are already driving change in warehouses and distribution centers, thanks to the same technology.

Interested in a specific market? Click a market below for current articles and news.

Automotive, Consumer, Industrial, Medical, Mil/Aero, Datacom/Telecom, and Transportation

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024