60-Year-Old SMA Connector Design Still Popular

SMAs represent the most connector sales in the coax connector category. This early, innovative design continues to serve microwave technologies into the 5G era and beyond.

Are you familiar with the SMA connector? Bet you don’t know all the hundreds of variations in use. Worldwide, SMAs have the highest dollar sales of all coax connector types, with current annual connector sales estimated to exceed $300 million. Adding in the value for cable assemblies, adapters, and housings that use SMAs could multiply that amount by several times.

The SMA was originally designed at Bendix Research Laboratories by Dr. John Bryant, James (Jim) Cheal and Vincent (Vince) McHenry in 1958 and began life as the BRM connector, an acronym for Bendix Research Miniature connector. A significant step in the microwave industry occurred in 1962, when they left Bendix and formed Omni Spectra Inc., where an equivalent to the BRM was pursued as the OSM (for Omni Spectra Miniature), which they designed to have low VSWR (voltage standing wave ratio) through 26.5 GHz. In 1996, the three engineers were honored by the IEEE MTT-S with the prestigious Microwave Pioneer Award, saying that this was “an entirely new approach to microwave construction for broadband, compact assemblies to use in missiles and spacecraft, as well as for replacement of waveguide and bulky coax in conventional applications at all microwave frequencies.” The OSM (future SMA) established the foundation for the miniature microwave connectors that are used today.

Cheal and McHenry, joined by Jim Kubota, who had been engineering manager at Omni Spectra, founded Southwest Microwave (SMI) in 1981, and developed an exceptional thick-walled SMA with uniquely stabilized Teflon that limited expansion at 165˚C to only about 0.001 inch at the interface. This SMA earned the title of SuperSMA; it was one of the first field-replaceable types and prompted industry usage of field-replaceable connectors for better performance and reliability, especially for hi-rel, medical, and aerospace applications.

Dr. John Bryant

Even today, most RF connector manufacturers (especially offshore) do not have the internal transmission line design knowledge or the specialized higher tolerance manufacturing capabilities used by Omni Spectra and SMI. From the start, many companies made look-alike copies of the SMA using MIL-spec drawings that defined the mating interface but did not detail internal construction. Many were barely useful to 3 or 5 GHz with degraded performance at higher temperatures (due to Teflon expansion at the interface), which is still true for many of today’s SMAs that nevertheless are acceptable for many current applications.

James “Jim” Kubota

MIL-spec documentation first occurred in 1965. Omni Spectra had copyrighted the term OSM, and therefore the OSM connector was designated by DSCC as SMA (for Subminiature Type A). Later, a smaller-than-OSM/SMA series was developed, termed OSSM and standardized as SSMA.

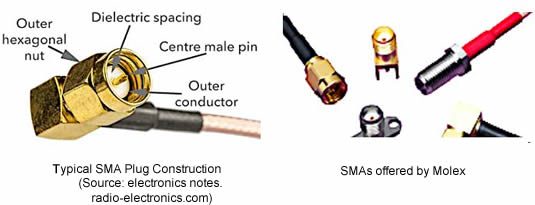

SMAs are standardized per MIL-PRF-39012 and CECC 22110/111, but most production is outside of spec-coverage (e.g., 39012 does not include field replaceable versions), or does not need to meet spec-approval for commercial applications. External appearance may belie the various versions that include:

- Thick wall plugs/jacks (for energy transfer and strength at mating interface).

- Brass housings (offering cost savings, usually plated gold over nickel) versus stainless steel. Alternate finishes include non-reflective black chrome.

- End launch and edge launch versions (for board I/O).

- 50 vs. 75 ohms (95 ohm and other impedance specials also exist).

- Incorporating field replaceable termination (with separate pin or seal accessories) vs. soldering to extended-length central contacts (extending rearward beyond the housing).

- Standard vs. Reverse Threaded (the latter is now known as RP-SMA).

- Non-magnetic options for medical, test, satellite, and quantum computing applications.

- Low PIM plugs/jacks for communication projects.

- Maximum frequency versions for 3 GHz, 12 GHz, 18 GHz, 26.5 GHz, and even 32 GHz.

- Various maximum operating temperatures (affects power handling and, if used, bead-retention).

- Polarized (with multiple Keyway Options).

- Unsealed vs. Pressure Sealed (moisture sealed) vs. Hermetically Sealed.

- Internal construction differences, including:

- Uncaptured vs. captured contacts, using epoxy or internal interference-fit beads. Lack of mechanical capture may permit insulator movement (or contact movement within the insulator).

- insulators secured by dimpling housings versus having interference-fit retention beads that secure contacts, insulators, and housings together.

- Insulators and contacts secured together using epoxy. They are easily identified by the two black epoxy spots in the housing.

- Smooth versus stepped or tapered internal cavity.

Amphenol RF’s SMA end-launch jack with gold-plated-brass housing. from Mouser Electronics. is mechanically dimpled to hold the insulator in place. Contacts may not be firmly captured or held in place by barbs, etc., and may move under temperature cycling. VSWR: 1.05+0.02 f (GHz) MAX. @ 0-18 GHz, (i.e., 1.36:1 @ 18 GHz), and 1.5:1 @ 18-26.5 GHz.

Amphenol RF’s SMA end-launch jack with gold-plated-brass housing. from Mouser Electronics. is mechanically dimpled to hold the insulator in place. Contacts may not be firmly captured or held in place by barbs, etc., and may move under temperature cycling. VSWR: 1.05+0.02 f (GHz) MAX. @ 0-18 GHz, (i.e., 1.36:1 @ 18 GHz), and 1.5:1 @ 18-26.5 GHz.

Epoxy-captured SMA jack by Pasternack Enterprises, from Digi-Key Electronics. Usually produced by drilling a hole through the connector after it is assembled and then injecting epoxy through the connector that will cure to provide a mechanical nail-like means to keep parts in position. Operating frequency can be DC to 18 GHz, with VSWR of 1.25:1. The housing may be gold-plated brass or passivated stainless steel. To reduce the RFI leakage “window” provided by the two drilled openings, suppliers may cover the holes with solder or silver-solder.

Epoxy-captured SMA jack by Pasternack Enterprises, from Digi-Key Electronics. Usually produced by drilling a hole through the connector after it is assembled and then injecting epoxy through the connector that will cure to provide a mechanical nail-like means to keep parts in position. Operating frequency can be DC to 18 GHz, with VSWR of 1.25:1. The housing may be gold-plated brass or passivated stainless steel. To reduce the RFI leakage “window” provided by the two drilled openings, suppliers may cover the holes with solder or silver-solder.

SMA female connectors called “jacks” comprise 90% of panel/box mount applications and are available in thread-in, bulkhead mount, or flange mount usually with 2 or 4 holes that are smooth or threaded/tapped, and many other choices. There are equivalent panel-mount versions with male (coupling nut) interface. Cables are primarily plug/male, with multiple means for attaching cables. Termination methods and operator technique affect results.

Since most applications (including 5G) using SMAs traditionally are up to 6 GHz, and some to 18 GHz, often designers do not know that SMAs are available up to 27 GHz. For needs above 20 GHz interconnect (such as the 5G band (n258) for 24.25-27.5 GHz, or 26 GHz local multipoint distribution systems [LMDS]), many users may unknowingly select 2.92 mm connectors that are several times the cost of higher-performance SMAs.

Special versions offer application benefits

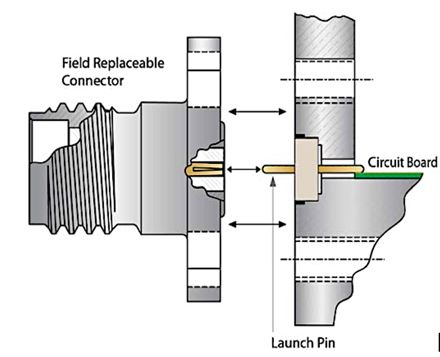

Field Replaceable Coax Connectors are preferred for hi-rel and sensitive microwave applications. Use of an intermediary pin or hermetic seal eliminates potential stress between the connector contact and mounting circuit from occurring due to parts’ movement/vibration or material expansion from temperature change. The connector’s rear socket usually is optimized to accept an accessory having a specific diameter. The connector has a 360˚ raised ring to assure proper grounding between the connector housing (outer coax circuit) and panel. Another benefit is that the connector can be removed without having to unsolder it from the assembly.

Field Replaceable Coax Connectors are preferred for hi-rel and sensitive microwave applications. Use of an intermediary pin or hermetic seal eliminates potential stress between the connector contact and mounting circuit from occurring due to parts’ movement/vibration or material expansion from temperature change. The connector’s rear socket usually is optimized to accept an accessory having a specific diameter. The connector has a 360˚ raised ring to assure proper grounding between the connector housing (outer coax circuit) and panel. Another benefit is that the connector can be removed without having to unsolder it from the assembly.

Reverse-polarity SMA (RP-SMA or RSMA) is an SMA variation that reverses the gender of the interface. The term “reverse polarity” refers only to the pin vs. socket of the connector’s contact pin and not to signal polarity. Non-intermateable with regular SMA, they are specified by the FAA for antenna applications. Besides reversing regular gender, the use of RP-SMA provides additional polarization options.

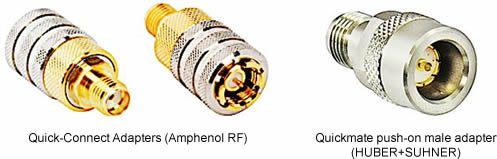

Quick-Connect and Push-On SMAs are useful for testing equipment or cables. A quick-and-dirty approach sometimes used is to remove the coupling nut and use the plug as a push-on test connector. However, this should not be done due to tolerances and mechanical “softness” of brass SMA housings (if stainless steel is not used) that could result in deformation due to wear and mis-alignment forces (mis-aligned mating also may damage contacts), etc. Instead, several suppliers provide special quick-connect versions with assured performance and dramatic reduction of mating time without requiring any additional tooling (such as wrenches) to confirm proper engagement. Products at left below by Amphenol RF have push-turn (rotational) thread-on, pull-off coupling to securely lock onto the mating connector. Most others have inline push-pull motion.

The extensive variety of SMA applications is illustrated by the many types of SMA adapters available. For example, Pasternack Enterprises’ online catalog offers same day or next day shipment for 186 between-series and 119 within-series adapters for a total of 305 different SMA adapters. (Next closest are BNC adapters with 174 different types.) For test applications SMA-to-7mm/APC-7 are offered as the 7mm (or APC-7) is the best test connector for DC to 18 GHz as defined by the IEEE 287 standard. Higher frequency test equipment usually requires use of coax connectors with air dielectric rather than SMA or any other connector with Teflon interface.

In closing, I’d like to note that we lost Jim Kubota to COVID-19 in 2021. He was the last of the SMA pioneers and a good friend. Dr. John Bryant died in 1997, Vince McHenry in 2015, and Jim Cheal in 2020. Bryant’s brilliant work influenced our entire industry, and I was fortunate enough to know the other three as friends and mentors. I spent daily time with Kubota (“getting trained,” as he put it), and McHenry was a teacher of “personal logic, international business, and mechanical fixtures.” Cheal could “see” fields whereas others had to use simulation software. Their incredible contributions created the communication and aerospace interconnect technologies that we have today, and they are all deeply missed. Many of their works can be seen in the historical displays at the IEEE Microwave Theory and Technology Society (MTT-S) show.

Dave Shaff will report on IMS 2022, the International Microwave Symposium, to be held June 19-22, 2022. Read his review of the 2021 event.

Like this article? Check out our other RF and Coax, and Circular Connectors articles, our Sensors & Antennas Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- New Circular Connectors Add to Multi-Billion Dollar Market - January 9, 2024

- Counterfeit Components Ground Airlines - December 12, 2023

- Cables, Connectors, Waveguides, and Hybrid Products for up to THz at IMS 2023 - July 11, 2023