What are Pogo Pins (Spring-Loaded Pins)?

Meet the Connector: Pogo Pins (Spring-loaded pins)

Pogo pins, also called spring-loaded pins, are electrical connector mechanisms known for their durability and their ability to provide and maintain an electrical connection that is resilient to mechanical shock and vibration. They are widely used in a variety of electronic applications and in the test industry.

The pogo pin is so named because the pin resembles a pogo stick. Although often used as a generic term, pogo pin is a registered trademark of Everett Charles Technologies (ECT).

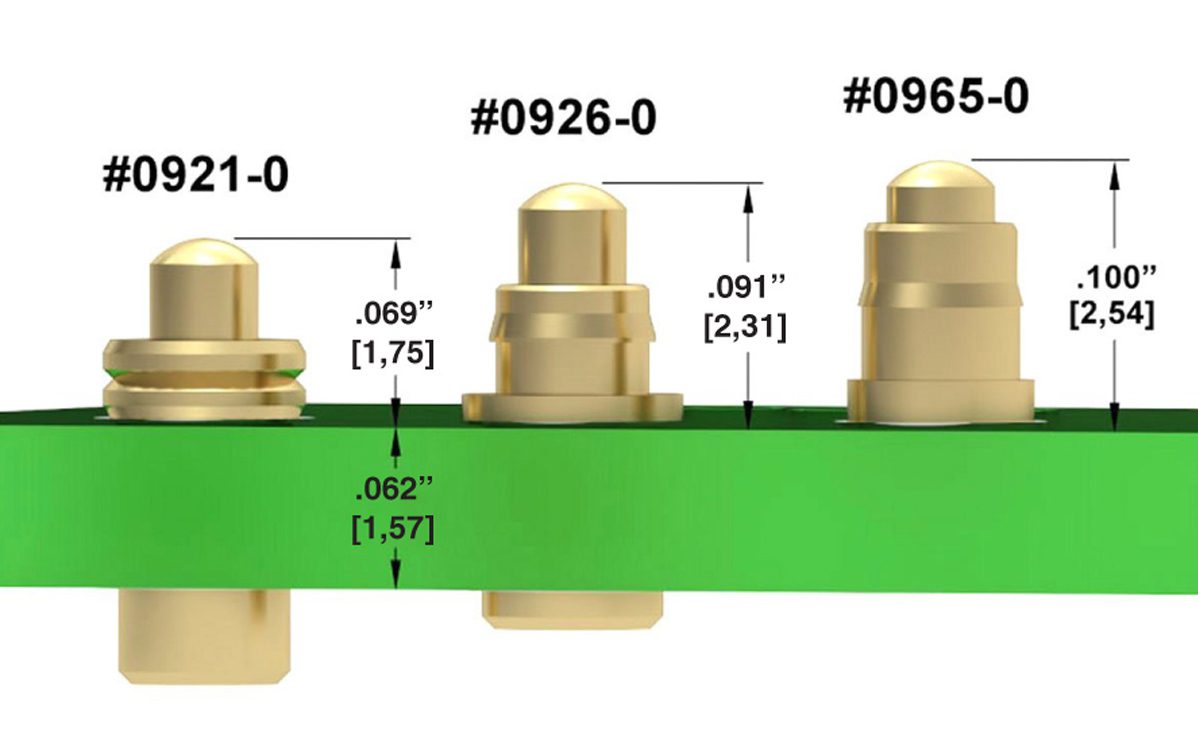

Mill-Max has five new low-profile spring pins that provide unique above PCB height profiles and through-hole or SMT options. The 0921-X and 0926-X series are through-hole mount and have either .0195″ (0,5 mm) or .0275″ (0,7 mm) rated travel (mid stroke). The 0965 is for surface mount applications and has .012″ (0,3 mm) rated travel (mid stroke).

Its unique construction has an integrated spring that applies a constant force against the back of the mating receptacle or contact plate. This prevents movement that could result in an intermittent connection.

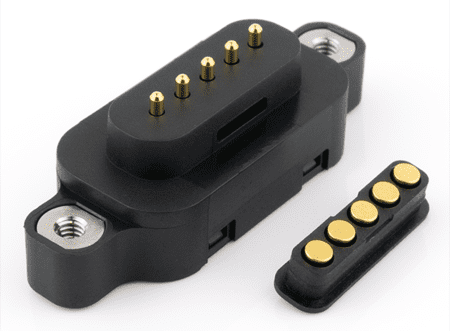

To complete the connection path, the mating receptacle that the spring-loaded pin engages, called a target or land, consists of a flat or concave metal surface. The target has no moving parts. It may be a plated area of a printed circuit board or a separate component in the connector assembly.

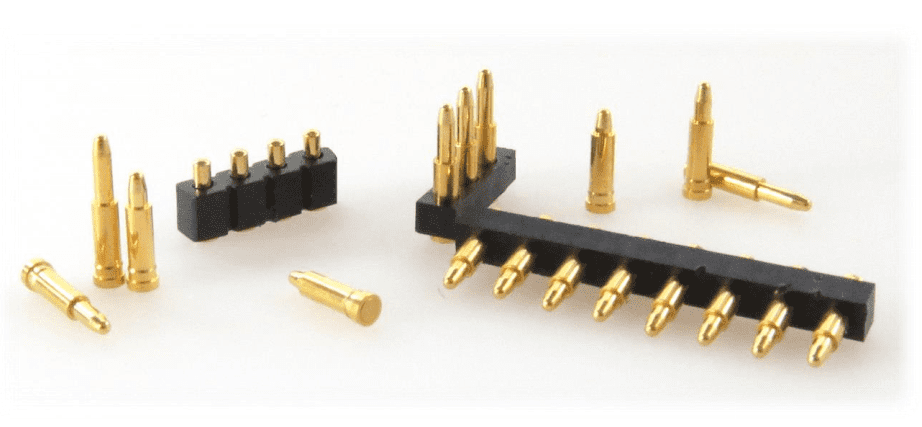

PRECI-DIP’s line of spring-loaded contacts, Series-0900-CLIP, can facilitate blind-mating and compensate for non-coplanar conditions. They are ideal for use in docking stations or in self-mating connectors when easy-handling and quick-mating are needed. The “CLIP” technology makes PRECI-DIP’s pogo pins highly reliable.

The turning and spinning fabrication process does not require a mold, which means spring-loaded pins can be produced in small quantities and at a lower cost than other contacts.

The pin construction includes a plunger, a barrel, and a spring. The spring is compressed and the plunger moves inside the barrel when force is applied. The barrel holds the plunger and prevents the spring from pushing it out when the pin is not locked in place. A slight gap between the plunger and the barrel allows the pin to move easily but can allow vibration to cause momentary disconnections. To avoid this and maintain continuous connection, the plunger typically has a slight tilt.

Manufacturers often develop proprietary variations of the interface. Sometimes a ball is added between the plunger and spring for greater stability and better performance.

Yokowo’s waterproof design has an IPX7 rating on both pogo and contact pad.

Design Notes

- Materials Brass or copper are commonly used as the base material for the plunger and barrel of spring-loaded pins, with a thin layer of nickel applied to the surface. Gold plating improves the durability and contact resistance. The springs are usually made of spring steel or copper alloys.

- Connector arrangement Spring-loaded pins are typically arranged in a dense array. In automatic test equipment, a “bed of nails” configuration facilitates the rapid and reliable connection of devices under test (DUTs). In high-performance applications, the arrangement must allow high reliability through many mating/unmating cycles and high-fidelity transmission of electrical signals. In matched impedance circuits, the pins may be arranged with one signal-carrying pin surrounded by grounded pins.

- Magnets may be added to improve the strength and reliability of the connection. This is done in consumer electronics and high-frequency data transfer applications.

Markets, Sectors, and Applications

Spring-loaded pins are used in many modern electronic applications and in the electronics testing industry. They are used with board-to-board connectors, ingress protected connectors (for consumer devices such as smart watches, or rugged computers), laptop battery terminals, laptop docks and chargers, high-frequency connectors (antennas), as well as for PCB testing, IC testing, and battery testing.

Suppliers

Digi-Key Electronics, Harwin, Mill-Max, Preci-Dip, Yokowo America Corporation

Related products:

Like this article? Check out our other Meet the Connector, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024