Remote Locations: How to Design Interconnect Solutions for Harsh Environments

Remote access to maintain electronic systems used in many harsh environments can be difficult or impossible. Strategic selection of interconnects can extend the life and ease the maintenance of this equipment.

Electronic systems and equipment used in hard-to-reach locations such as space, mountain-top observatories, deep sea rovers, or inter-continent data links face a common challenge. These remote and harsh operating conditions make it extremely difficult – if not impossible – to maintain, upgrade, or repair electronic equipment.

Environmental conditions can prevent human technicians from accessing components, including interconnects, for repair or replacement, even when they are close at hand. Radiation, vacuum, pressure, and extreme low or high temperatures may prevent easy access and maintenance. Operating conditions must be considered when selecting interconnect solutions for harsh environment applications.

How nuclear operating conditions influence the design of interconnects

The nuclear environment is a good illustration of the severe operating conditions to which interconnects can be subjected. The presence of radiation, vacuum environments, and extreme temperatures challenge the life span and performance of connectors, cables, sensors, and insulation materials with obvious limitations on personnel access. Both mechanical strength and electrical performance will be affected by this extreme environment, leading to premature aging and eventually failure of equipment.

Small modular reactors (SMR) and other newer reactors in development have exacting requirements, which makes the design of interconnect solutions even more challenging. Additionally, high temperatures and radiation can degrade components that initially meet these requirements. It is therefore of paramount importance to understand how each material ages under specific conditions, so that as its characteristics evolve, required performance is maintained throughout its expected use life.

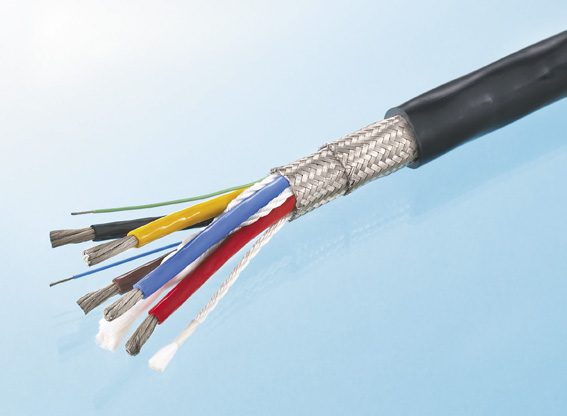

Interconnect solutions for harsh environments begin with insulating materials specifically designed to resist radiation and maintain guaranteed electrical performance should be employed in these designs. Materials that offer flexibility can also provide cables with additional support to meet these specific requirements.

A flexible 1 kV Poliax insulated cable assembly terminated with an Axon’ Cable round connector. This cable assembly, which is designed to resist 6 MGy radiation, is used in the Atlas detector (CERN particle collider). The confined installation area requires flexible cable assemblies with compact connectors.

Intervention on site by an Axon’ Cable engineer: The density of cabling in the Atlas detector makes it difficult to access the links. (Photo courtesy of CERN)

High-voltage cables and splices (>50kV) made by Axon’ Cable for the ITER nuclear fusion reactor. The system consists of cables insulated with an Axon’ special material that requires an innovative installation process. These cables are connected in a glass fiber/resin splice that can withstand high-energy radiation and extreme temperature variations (cryogenic temperature of 4 K).

Interconnect solutions for underwater equipment: watch out for the pressure!

Subsea applications include systems installed on the seabed, like pipelines or data cables; vehicles, such as submarines or rovers; and surface installations like oil rigs and ships. In terms of constraints, high mechanical stress related to pressure is combined with corrosion caused by salt water. In this case, waterproofing plays a key role to maintain the integrity of the electrical insulation around the cable or interconnect. These kinds of applications usually require high voltage with partial discharge-free insulation. Here again, the choice of materials does really matter, but even more important are the construction of each interconnect component and the design of the interfaces. The way the cable elements are constructed and assembled provides the resistance to the huge pressure exerted in the bottom of oceans.

Heating cables for pipelines made by Axon’ Cable. This custom-designed cable is made with a special insulating material able to provide the best compromise between electrical and mechanical performance. The custom process provides pressure resistance over very long lengths.

Protecting people and materials

Inside a manned underwater vehicle, there is no direct exposure to pressurized saltwater, but even the slightest risk to the safety of the crew must be considered. The key issue is clearly to avoid any risk of fire, while saving space and facilitating integration with a miniaturized flexible cable.

The main objective is, therefore, to select materials that will not burst into flames, and that will not release opaque, toxic, or corrosive fumes when burning. In this case, the best option is low-smoke halogen-free insulating materials with fire-retardant properties.

Axon’ low smoke and halogen-free composite cable with fire-retardant properties are used in submarines. Its high flexibility allows for easy installation.

Remote access and no access at all

When everything has been done to protect the safety of personnel and optimize the lifespan of equipment and this is still not enough, the last resort is to send in robots as an extension of the human arm. These robots, which handle or maintain the electronic systems, are subjected to the same harsh environment, with the added challenge of needing good flexibility to allow for their movements. Interconnect solutions for harsh environment robotics, including cables and cable assemblies, must be ruggedized against the environmental challenges, and miniaturization and weight-saving properties are typically also a priority.

Axon’ cable assembly made with a radiation-resistant Flexorad high flexlife power and data cable terminated with round connectors. The high flexibility of the cable enables applications such as the arms of rescue robots to move easily.

In space-restricted areas, flat flexible cables (FFC) designed to connect PCBs, devices, or actuators are a good solution. They are usually insulated with polyester or with polyimide for a higher temperature resistance. For repeated movements of the robot, high flexibility of the FFC can be achieved with very thick conductors and very thin insulating material.

Flexlife test of Flat Flexible Cables designed by Axon’ Cable. Extra flexible versions with 25 µm thick conductor and very thin polyester can reach 70,000,000 cycles (flexlife) with a 10 mm bend radius. This is an ideal solution for dynamic applications including robotics.

Interconnects are more than a sum of components

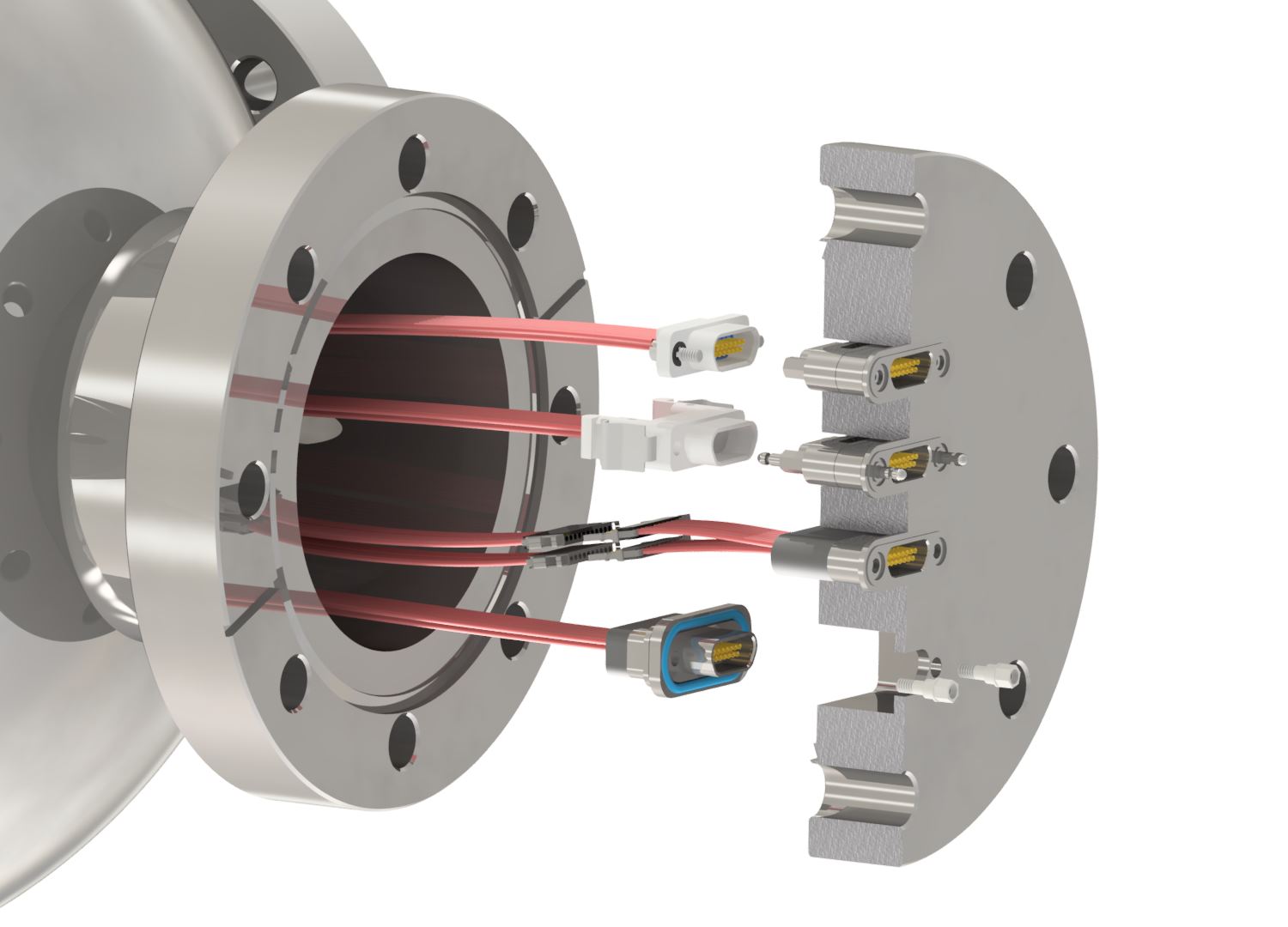

If not properly designed, interfaces between devices in electronic systems can be the weak point. This is even more critical in severe environments, including remote locations. For example, a hermetic system might need a hermetic feedthrough and matching interfaces with both air side and vacuum side cables. All different components can work in different environments but they all serve the same function. It is of paramount importance to consider the whole interconnect solution as a fully integrated system, rather than a sum of components, especially when it comes to extending the lifetime of the system or eliminating the need for maintenance.

Example of a complete solution with Axon’ Cable’s HermAx hermetic connectors and feedthrough in a hermetic system.

Visit Axon’ Cable to learn more about interconnect solutions for harsh environments.

By Pierre-Yves Mikus, PhD, R&D Manager; Armand Hattat, Sales Engineer; Christophe Tisserand, Sales Manager; Sandrine Hermant, Marketing Manager Axon’ Cable

Like this article? Check out our other How to Specify, Mil/Aero Market articles, and our and 2023 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.