Precision Interconnects Make Indoor Agriculture More Productive

Vertical farming operations bring food crops indoors for protection from extreme weather, continuous growing seasons, and increased production. Guided by sensors and enabled by LEDs, these smart farming strategies offer a solution amid growing climate challenges.

Indoor agriculture may be our last hope for a flavorful future. Severe drought plus pesticide-resistant insects have decimated the hot pepper crops in Mexico, India, and other pepper-growing regions, causing Sriracha and other businesses that need the ingredient to halt production. Your bratwurst or pretzel might have to go without mustard, due to drought in top mustard seed producers France and Canada. Climate change isn’t just drying up our favorite condiments, unprecedented weather extremes are destroying numerous other crops and impacting food supplies around the world. Electronically controlled indoor or vertical farming operations offer protected, predictable, and optimal growing conditions.

With another 2.3 billion mouths to feed on Earth by 2050, technology will be a critical part of future agriculture solutions. In the 1980s, NASA developed the first vertical farm in the U.S. The agency sought to produce food using the least amount of energy while maximizing the growth effects of artificial light source. Researchers found using a combination of red and blue LED lights provide the optimal photons for plant growth. Today’s vertical farms have fine-tuned this lighting strategy to the ideal light conditions each type of produce requires through all stages of the plant’s lifecycle.

“The blue light plays a role in many plant processes, such as the formation of secondary metabolites. The illumination with spectra individually created from the different wavelengths of monochromatic LEDs becomes even more efficient with the new mid-power LEDs, yet at the same time more homogeneous,” said Johann Waldherr, agricultural scientist with Würth Elektronik’s LED team. Würth is working with Dürnast Greenhouse Laboratory Center at the Technical University of Munich, along with other research institutions, to develop LED products for indoor agriculture.

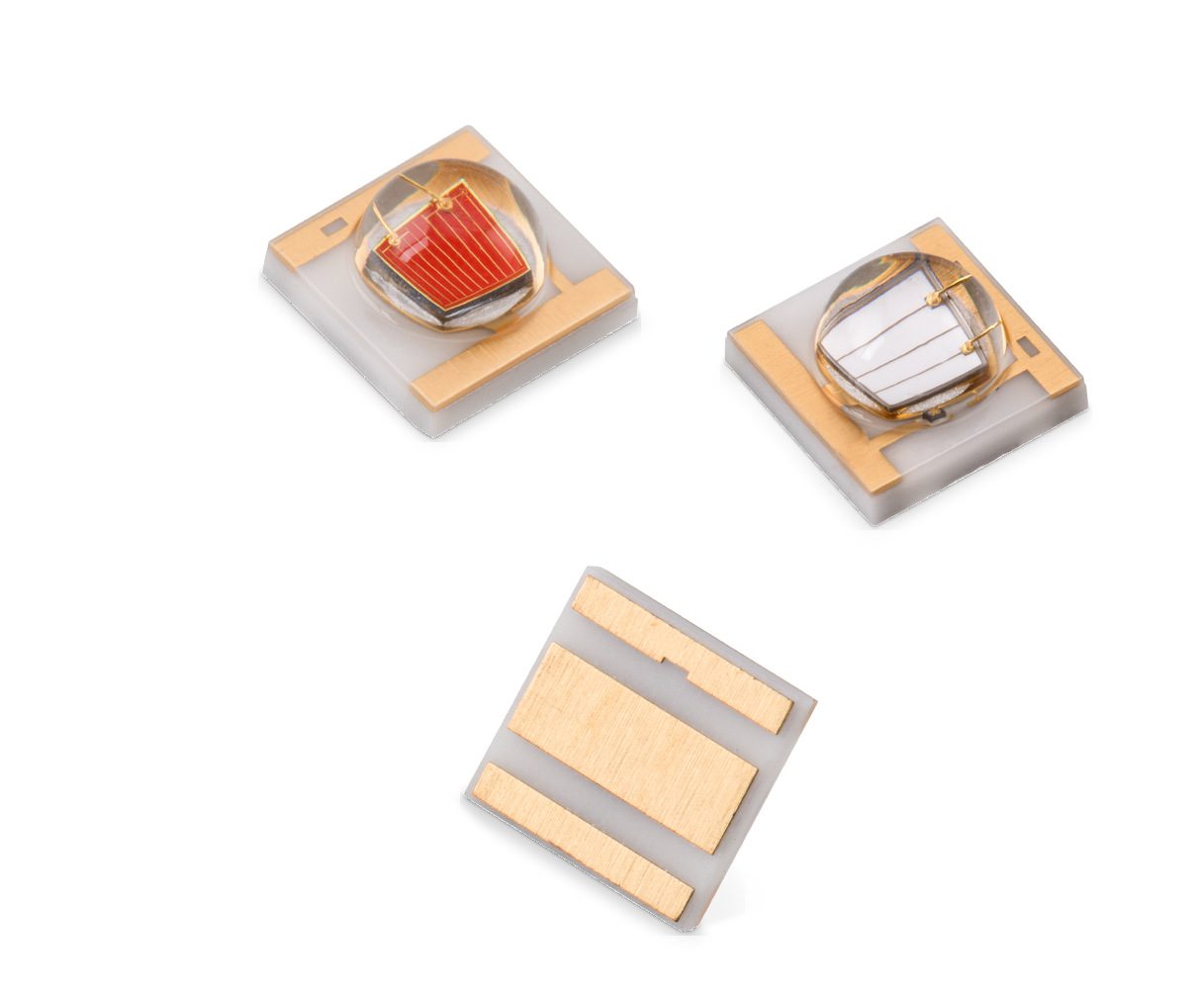

Würth Elektronik’s extensive range of horticulture LEDs include the WL-SMDC SMT Mono-color Ceramic LED Waterclear (above) for indoor agriculture, aquariums, and grow boxes. The WL-SMTW series LEDs emit light of the wavelengths 450 nm (Deep Blue), 660 nm (Hyper Red) and 730 nm (Far Red) to control plant growth through specific light mixtures. Würth’s Lighting Development Kit offers additional horticulture solutions.

“It is possible to create specific lighting recipes for a wide range of the horticulturist’s quality parameters, such as more blossoms, more fruit, more biomass, more vitamins, and so on,” said Waldherr. “As an innovation partner with research institutions, we conduct intensive research and share our knowledge with our customers.”

Weidmüller’s Industry Light (WIL) provides extremely small and robust lighting solutions with IP67 sealing and three-cone configurations for precisely controlling light arrangements. An M12 connector provides easy installation.

In addition to using LEDs to mimic a natural growing season, vertical farming operations must monitor and control carbon dioxide in an optimized combination with temperature, humidity, and ambient light. Accurate and reliable CO2 measurement is essential for the operation of supplemental CO2 systems. CO2 sensors support wired or wireless indoor agriculture climate control systems.

TTI Inc. offers Telaire T3000 Series CO2 sensors from Amphenol’s Advanced Sensors with IP67 sealing for harsh environment conditions where moisture, debris, temperature fluctuations, and chemical exposure are present. (Visit the TTI Sensor Resource Page or download the Amphenol Application Spotlight.)

LED technology is guided by the Zhaga Consortium, a global lighting-industry organization that aims to standardize interfaces of components of LED luminaires, including LED light engines, LED modules, LED arrays, holders, electronic control gear (LED drivers), connectors and sensing/communication modules. Amphenol Communications Solutions, Phoenix Contact, TE Connectivity, WAGO, and other member companies collaborate to develop LED and interconnect products and specifications and standards for the lighting industry. Zhaga Book 20 defines a separable mating interface for sensors in intelligent building networks such as vertical farms. Amphenol Communications Solutions’ FLM Series connectors were chosen as the Zhaga Book 20 Standard.

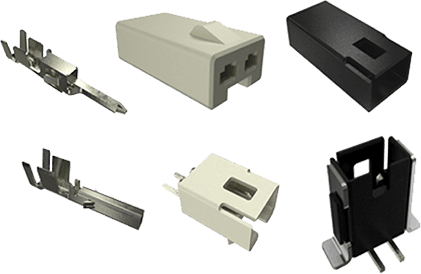

Amphenol Communications Solutions’ FLM Series, available from TTI Inc., connect modules to LED drivers and control systems. These Zhaga standard connectors are compatible with the DALI-2 smart interface protocol used for data transfer between indoor luminaires and sensors and communication modules. The FLM series is designed for easy field service and replacement.

“Design factors such as poka-yoke features to prevent incorrect mating and an integrated latch system ensure a reliable connection made the Amphenol product ideal for LED applications,” said John Sandy, supplier marketing manager at TTI Inc. “Designers are looking to make luminaires upgradeable in the future and connect to lighting controls systems which can be facilitated by Zhaga interconnect solutions. The combination of LED lighting and IoT sensors, facilitated by the Zhaga Book20 solution, allows customers to maximize energy conservation and annual savings. Most customers are looking for cost savings resulting from the transition to LED luminaire solutions. These savings can be further enhanced by adding additional functionality such as presence sensing, daylight harvesting, etc.”

Specialized interconnects support the precision and modulation needed for vertical farming, while also enduring harsh environment conditions such as moisture, debris, temperature fluctuations, and chemical exposure. Industrial interfaces, including M-type circular connectors, play a crucial role in delivering power, data, and signal to LED, irrigation, and sensor systems used in vertical farming operations.

JPC Connectivity’s waterproof line of M8s and M12s are available with IP65 and IP67 sealing to serve in industrial IoT systems, including Industry 4.0 automation control equipment and signal transmission, power, sensor, and cable connections.

Turning a natural process into an industrial operation is a complex endeavor that requires continuous advancement in electronic systems. Moving agriculture indoors protects crops from unpredictable weather and poor growing conditions but vertical farming presents new challenges. Significant energy use must be balanced with heat control, electronics must be selected for environmental ruggedness and UV resistance, and systems must be easily upgraded as technology evolves. Specialized interconnects will continue to provide increased efficiency to help improve the responsiveness of sensor systems and increased precision in lighting and liquid nutrient applications. As agriculture merges with industrial automation, growers will be able to maximize crop yields with minimal interaction.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Amphenol Communications Solutions, JPC Connectivity, Phoenix Contact, TE Connectivity, TTI Inc., Weidmüller, WAGO, and Würth Electronik.

Like this article? Check out our other Automation, Sensors, Waterproof, circular connectors articles, our Industrial Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024