One Size Does Not Fit All: Optimized RF Connectors are Crucial to System Performance

New locking miniature push-on (TLMP) and locking miniature blind mate (TLMB) connectors overcome SMP connectors’ susceptibility to EMI and EMC interference, and liquid and salt ingress. These rugged connectors are suitable for use in harsh mil/aero environments.

RF reliability and performance depend on a perfect fit between the system design and specific application needs. One size does not fit all; the performance of these systems is heavily determined by RF connectors and how they fit together. Some RF installations demand standard products, while others need custom solutions to meet unique requirements.

Environment, temperature, vibration, density, and frequencies are just a few factors influencing performance requirements. Installation and maintenance must also be considered – for example, if the RF system is operating in outer space, it needs to be maintenance-free. Similarly, if components will be used for 5G networks, where high cable density is present, easy handling is required to make reliable connections within small spaces.

Several optimized RF connector designs, including bundled solutions and locking miniature connectors, were created to address needs not fulfilled by standard connectors.

Bundled solutions

Bundled solutions permit installation in tight spaces; instead of connecting multiple threaded connectors, just one will do the job. This strategy is faster and easier to install and maintain and provides one reliable, high-performance connection. Bundled design solutions are popular in applications such as space and avionics, where cable installations and rising operating frequencies demand coaxial cables and connectors that can deliver high signal integrity and reliability.

Industry Example: 5G Multiport Connectors and Bundled Cable Assemblies

To deploy 5G, existing broadband networks must be densified, which means more cell sites must be deployed in more locations to get the signal closer to users. 5G applications use antennas with multiple in/multiple out (MIMO) feeds, which substantially increases the number of RF ports.

5G antennas are also shrinking in size as higher frequency bands are used to accommodate higher bandwidth requirements. More antennas and the RF cables and connectors needed to power them must fit in a much smaller space. This type of equipment is also packed much closer together than traditional telecom towers; some cells are only 100 yards apart.

Designing an interconnect system that will perform well and withstand extreme environmental and technical conditions is a challenge. With so many components in such a small space, maintenance can be challenging. If an interconnect fails, it can be hard to troubleshoot the exact one. Moreover, installation can be a time-consuming, labor-intensive, and logistical nightmare. Hooking up the right cables, the right ports, and torquing are all concerns. Proper weather sealing is also necessary; it is imperative to ensure that the seal is good but not over-torqued. In addition, minimizing size and weight are also key goals.

New bundled coaxial cable and multiport connector solutions support optimal speed, coverage, and latency requirements for 5G installations. A bundled cable design can help create the perfect flexible antenna jumper for applications requiring multiple runs. A spiral configuration of multiple flexible and ultra-flexible low PIM jumper cables can be created under a common polyurethane outer jacket to promote easy installation and improved operation. The individual coaxial cable runs are spun together in a way that easily flexes, essentially creating a bundle, which is then run through a large jacket extruder where a ripcord is placed.

This design enables four or five individual cables to be fed into the back of a multiport connector such as the industry-standard MQ4/MQ5 designs that encompasses a four-contact connector and a five-contact connector. MQ4/MQ5 connectors incorporate multiple RF ports, greatly reducing the number of cables to hook up, saving labor, and creating a more rugged, weatherproof, and UV resistant solution.

TMQ4/TMQ5 bundled coaxial cable solutions from Times Microwave Systems

Using the four- or five-conductor solution eliminates the need to create individual weather seals, resulting in tremendous labor savings. Furthermore, it reduces the need to worry about coupling torque. This is critical because all it takes is an error on just one weather seal to create a point of ingress for water that could create a multitude of problems and even potentially shut the system down. With a bundled solution, the connection between the male and female cluster connectors is sealed to IP67, as are the connector bodies and the transition from the cluster connector to the bundled cable. Any potential system troubleshooting becomes much easier.

Finally, the possibility of hooking up the wrong cable to the wrong port is eliminated. The solution is keyed, so the cables can only be hooked up a certain way—no torque wrenches, know-how, or special technique required.

Locking miniature push-on and locking miniature blind mate connectors

The RF industry has been using sub-miniature push-on (SMP) connectors for decades. SMP connectors install by simply pushing connectors against each other to connect and then pulling apart to disconnect. Installers can mate connectors without threading, eliminating the need for tools. The SMP enables a small amount of radial misalignment during mating, which would be unacceptable with threaded connectors.

While SMPs are a valuable connector option for many designs, they pose problems as applications demand higher frequencies. One critical issue is shielding and electromagnetic interference (EMI). The SMP’s design affects other equipment in the same environment in terms of electromagnetic compatibility (EMC). The connector’s signal leakage issues often result in failed EMC tests and the SMP’s lack of proper electrical bonding and shielding exposes the conductor’s signal to external influence.

The SMP’s design is also susceptible to ingress from saltwater, fuel, and other contaminants. The lack of an environmental seal due to their mechanical openings makes SMPs prone to corrosion and failure. Another problem arises when SMPs are used in high-vibration applications; their easy connect/disconnect design makes them susceptible to de-mating in high-vibration environments.

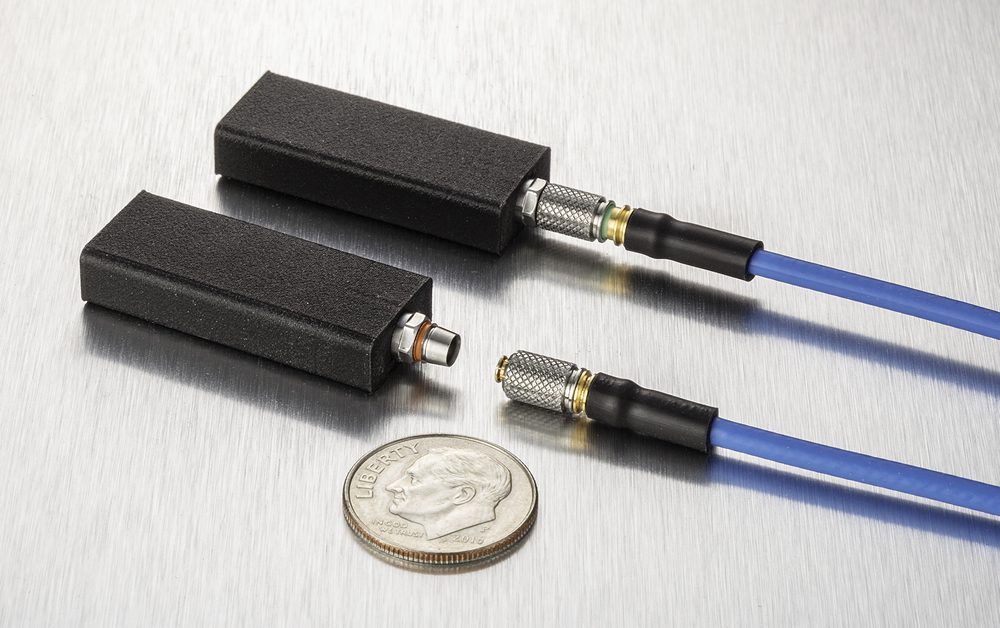

New locking miniature push-on (TLMP) and locking miniature blind mate (TLMB) connectors are designed to overcome SMP connectors’ susceptibility to EMI and EMC interference, and liquid and salt ingress. These rugged, sealed-design connectors are suitable for use in harsh environments.

The TLMP/TLMB connector retains the small form factor of the SMP and adds improved environmental, shielding, and power capabilities, with a frequency range from DC to 60 GHz. A positive locking feature with visible green (locked) and red (unlocked) color coding prevents de-mating under vibration and shock. At the same time, the high-power/high-voltage design overlaps the insulators, cutting off a direct path to the ground from the center conductor to the outer shield to enable higher-power or higher-voltage functionality.

The RF connector’s slots are also entirely covered with the mating part, preventing signal leakage, thus improving EMI and EMC. The TLMP has a latching mechanism that significantly improves mating retention, making it a better option than SMPs that use threaded bodies or similar designs that have attempted to overcome the problems of traditional SMP connectors. The mating connectors are also designed for board-level mounting. The TLMB version has fully shrouded tine protection.

The TLMP/TLMB was created for high-reliability, high-vibration environments such as military and aerospace. Areas where EMI may be an issue, such as shipboard or aircraft applications, need an environmentally sealed and shielded connector. While an SMP is at risk of disconnection in high-vibration environments such as aircraft carriers or weapons launches, a locking miniature push-on connector provides a reliable and secure connection.

Today’s challenging RF applications require a new generation of interconnect solutions that can ensure high reliability, high resistance to vibration, and high density. Innovations in this area include multiport, locking miniature push-on, and locking miniature blind mate connectors.

When it comes to selecting RF connectors and cables, partnering with a supplier whose engineers can design an optimized solution for the application’s unique needs will produce better electrical, mechanical, and environmental performance, as well as easier handling in the field. Look for a supplier with a long history of building quality cable assemblies and connectors, along with the skill, processes, techniques, and materials to bring custom solutions to life.

Visit Times Microwave Systems to learn more.

Like this article? Check out our other Harsh Environment, High-Reliability and How to Specify articles, our Mil/Aero Industry articles, and 2022 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.