ODVA Standards for Industrial Automation

ODVA standards help ensure interoperability, safety, and security in facilities that that are integrating advanced information and communication technologies into industrial automation.

From materials sourcing to the production of goods to final-mile logistics, multiple levels of connectivity have become an essential part of the manufacturing world. Facilitating seamless communications between a wide range of devices and systems used in industrial automation depends on network technologies such as those based on the Common Industrial Protocol (CIP).

Since its inception in 1995, the standards group ODVA (Open DeviceNet Vendors Association) has helped ensure open, interoperable communications between networks with protocol solutions like DeviceNet, EtherNet/IP, CompoNet, and ControlNet. Interconnect suppliers that are members of ODVA play a key research and development role, updating ODVA standards and developing new ODVA-compliant products to meet evolving industry needs.

ODVA-compliant connectors, cable products, sensors, and antennas form the backbones of smart factories, facilitating communications, operations, and security in automation networks. “We invest heavily in R&D, which ensures we are on the cutting-edge of connectivity and able to anticipate the market needs for today and tomorrow,” said Jon DeSouza, president and CEO of HARTING Americas, an ODVA member since 2020. Other members include Amphenol LTW, Hirose Electric, METZ CONNECT, Molex, Phoenix Contact, TE Connectivity, WAGO, and Weidmüller.

“Weidmüller is heavily involved in standardization. We have members on the Profibus user organization (PNO) and the Open DeviceNet Vendors Association (ODVA),” said Simon Seereiner, head of product management SAI & IE at Weidmüller. “We use our specialist expertise in the area of standardization for cables and plug-in connectors to help implement the correct standards.”

ODVA standards have transformed production lines, bringing Industry 4.0 and IIoT efficiencies to numerous industries. In food and beverage processing plants, CompoNet plays a pivotal role in connecting sensors and actuators across various stages of production. DeviceNet and ControlNet ensure reliable communications and help manufacturers maximize production while adhering to strict quality standards.

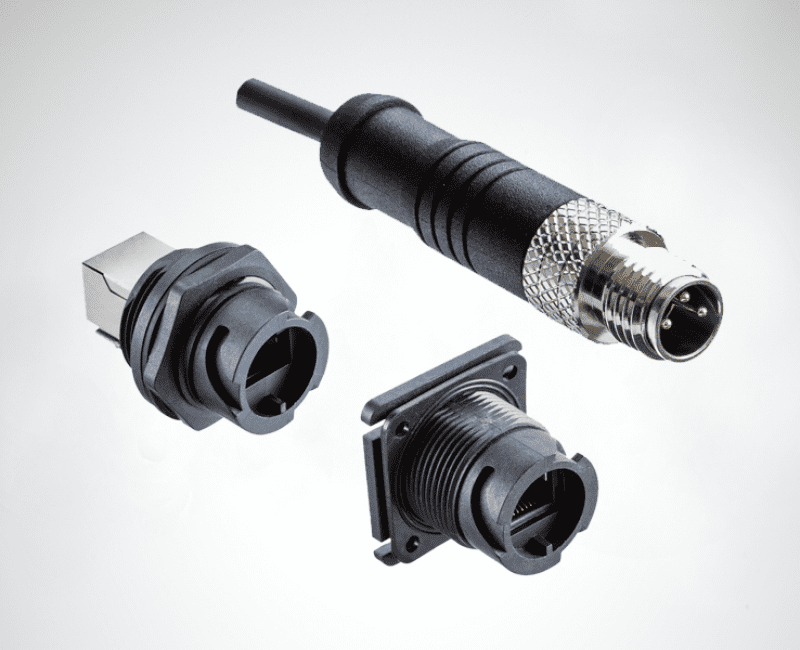

Amphenol LTW ODVA RJ connectors comply with protection class IP67 and offer Cat.5e and Cat.6A transmission speed with a rated current up to 1.5A.

In the automotive sector, ODVA standards have transformed production lines, facilitating seamless communication between robotic arms, conveyor belts, and quality control systems. EtherNet/IP enables high-speed data exchange, while CIP Safety ensures the safety of workers and equipment.

In pharmaceutical manufacturing, where precision and compliance are non-negotiable, CIP Security provides peace of mind. By safeguarding sensitive data and ensuring the integrity of processes, ODVA standards enable pharmaceutical companies to meet regulatory requirements while maintaining operational efficiency.

Security is an increasing focus for the organization. While greater connectivity brings myriad possibilities for production improvements, expanding a network has the potential to expand points of ingress. In late 2023, ODVA issued CIP Security, a cybersecurity network extension for EtherNet/IP. This new, device-based firewall enhances intrusion deterrence with a simple traffic filter similar to how the IP Tables program enables a firewall to be set up in Linux.

Al Beydoun, president and executive director of ODVA, said, “The prevention of unauthorized IP address and port numbers from accessing CIP Security enabled EtherNet/IP devices allows for another layer of protection for critical industrial automation applications as a part of a defense in depth approach. The addition of the device-based firewall profile for CIP Security is another important update to continue the fight against malicious cyber intrusions that can lead to financial and reputational loss.

TE Connectivity’s ODVA LC rugged fiber connectors are a low-cost and easy-to-use connector for harsh environment applications, available in cable assembly and connector product types, multimode or single mode options, with duplex, plug, and receptacle styles

What are the ODVA standards?

DeviceNet: In a manufacturing facility where sensors, actuators, and controllers seamlessly communicate, DeviceNet facilitates real-time control and monitoring, providing a robust network protocol for industrial automation.

EtherNet/IP: In an era dominated by Ethernet, EtherNet/IP extends CIP to standard Ethernet networks, enabling high-speed data exchange and real-time control capabilities. This standard revolutionizes industries by leveraging the ubiquity and efficiency of Ethernet.

ControlNet: For applications demanding high-speed and deterministic communication, ControlNet is the backbone of industrial control systems, ensuring seamless data exchange for critical operations.

CompoNet: Connecting field devices across vast manufacturing plants with CompoNet provides flexible and cost-effective protocol connectivity, enhancing efficiency and productivity.

CIP Safety: Safety is paramount in industrial environments. CIP Safety provides a robust framework for ensuring the safe operation of machinery and equipment, mitigating risks and ensuring compliance with stringent safety regulations.

CIP Security: As cybersecurity threats loom large, CIP Security steps in to safeguard industrial networks. With features like authentication and encryption, it fortifies systems against cyber-attacks, ensuring data integrity and confidentiality.

Phoenix Contact gateways allow different industrial protocols to work together, in a single network. Serial device servers provide a simple pathway when migrating legacy serial devices to Ethernet protocols. The new Modbus to EtherNet/IP gateway offers easy and intuitive web-based configuration for mapping Modbus data over the EtherNet/IP.

By fostering interoperability, enhancing safety, and fortifying security, ODVA standards help industries achieve efficiency, productivity, and innovation. The fourth industrial revolution is still underway, and ODVA will continue to play a role in the development of safer, more productive, and more connected manufacturing.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Amphenol LTW, Hirose Electric, TE Connectivity, HARTING, METZ CONNECT, Phoenix Contact, WAGO, and Weidmüller.

Like this article? Check out our other Automation and Standards articles, our Industrial Market Page, and our 2023 and 2024 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024