Improving Device Reliability with Spring-Loaded Contacts

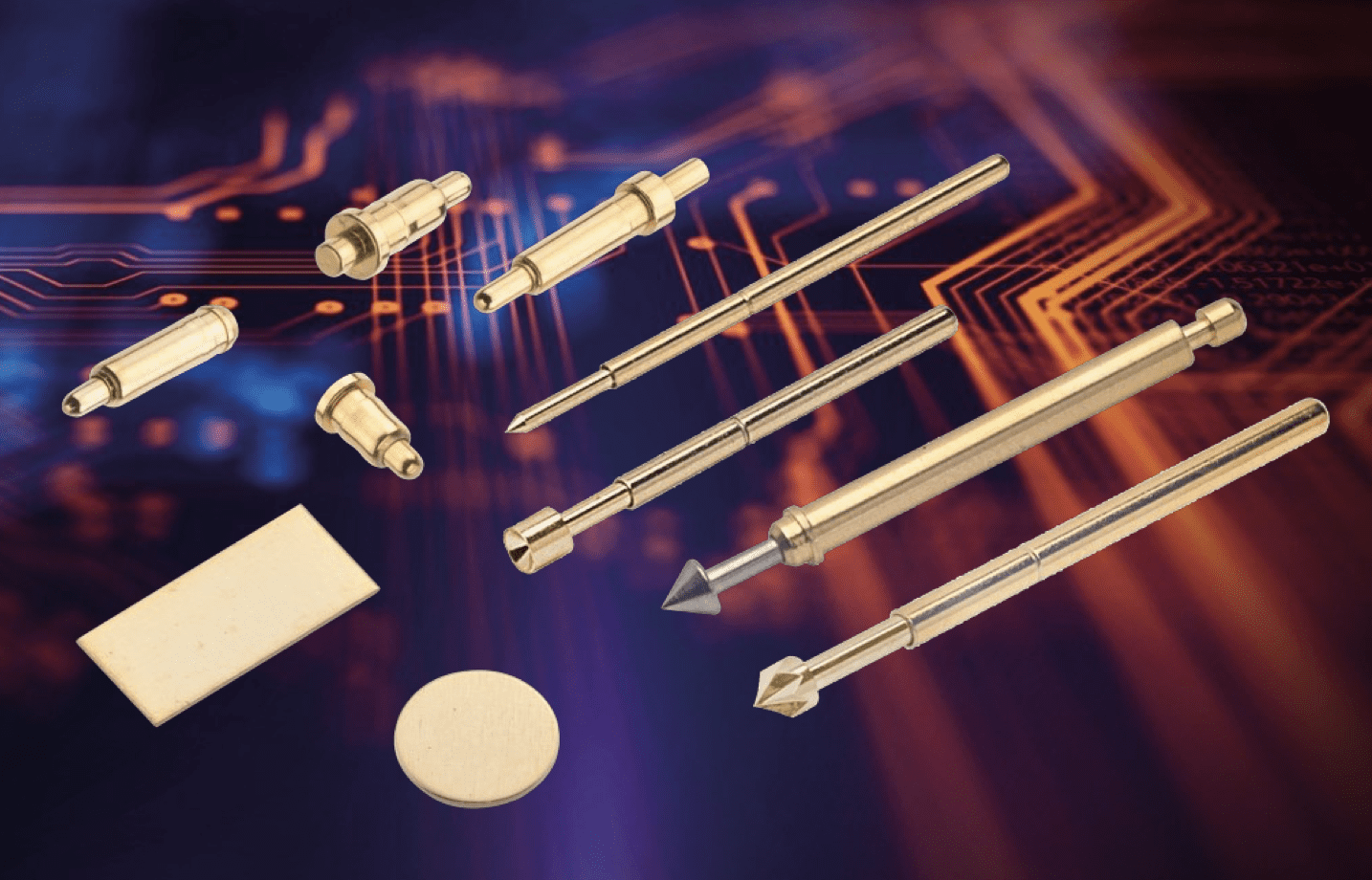

Spring loaded contacts, commonly called pogo pins, are essential in many electronic devices because of their excellent durability, tolerance, and wide range of applications. As the growth of the device market continues, these contacts are finding more use than ever.

Spring-loaded contacts or pins, also known as pogo pins, are not just the preferred contact, they are essential in many electronic devices. Spring-loaded pins facilitate efficient and reliable electrical connections between printed circuit boards and other critical components. Their excellent durability and tolerance gives them utility in a wide range of applications for both battery charging and data transmission. The small contacts are commonly used in charging terminals, including wireless charging and fast docking. They have a place in consumer electronics, portable medical devices, wearables, and handheld electronics used in a variety of markets.

The spring-loaded pin category features a wide variety of options, which can make it challenging to choose the best connector for an application. Specifying the wrong type of contact for a system can lead to inferior connections, negatively affecting overall device reliability.

Pin construction

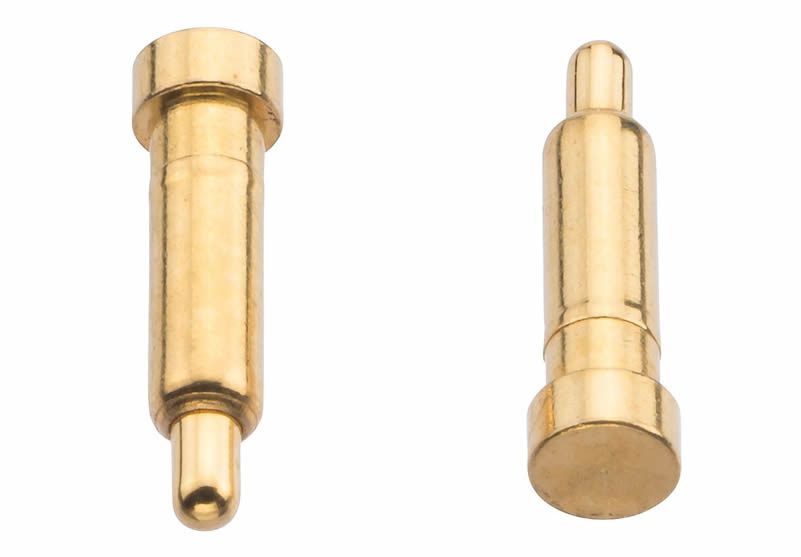

Pogo pins are spring-loaded contacts, so named because they resemble a pogo-stick. The pins consist of a plunger (head), a barrel (body), and a fully integrated coil spring which provides the spring force required to maintain positive contact. The connection type is a surface-to-surface connection that is maintained by the spring force.

Spring-loaded pins are available in two styles: Surface mount pins which have a flat bottom surface for easy soldering to a PCB and surface mount pins with location pegs for board location and added stability. The pegs can also be soldered as a through board termination.

When they are depressed from the top, a reliable electrical connection is established, either through the spring or via the plunger contact with the barrel. The connected contacts are held together against the spring force by other systems built into the equipment itself, such as locking toggles or spring hinges.

The plunger and barrel are typically made from a copper alloy material electroplated with hard gold to ensure excellent electrical conductivity, durability, and corrosion resistance. The springs are usually stainless steel and each pin is precision-machined to ensure high-quality contact.

Design advantages

Spring-loaded pins have many advantages compared to other types of connectors, namely:

Allow flexibility on mating height. The springs in the pins allow for flexibility in the mating height of the boards. This is particularly advantageous when other devices control the board-to-board distance as the springs adjust to any change in board height.

Maintain a positive force against a mating surface. A good, constant, and reliable contact is made between surfaces, thanks to the positive spring forces, which result in excellent conductivity and a stable current flow.

Tolerate lateral mating misalignment. The moving contact surface means that the pins can withstand lateral mating misalignment, which provides higher reliability where other connectors would fail.

Provide durability. The round profile of the plunger and the use of a hard-wearing gold finish, combined with a stainless-steel spring, means there is minimal friction and wear when connections are made. As a result, spring-loaded pins are extremely durable, and can withstand more than 10,000 mating cycles. Electronics designers specify these contacts to improve the reliability and quality of their devices.

Reduces height. The pin design and the compressed connection means they can be extremely compact and, as a result, boards can be stacked closely together. This saves space so devices can be designed smaller.

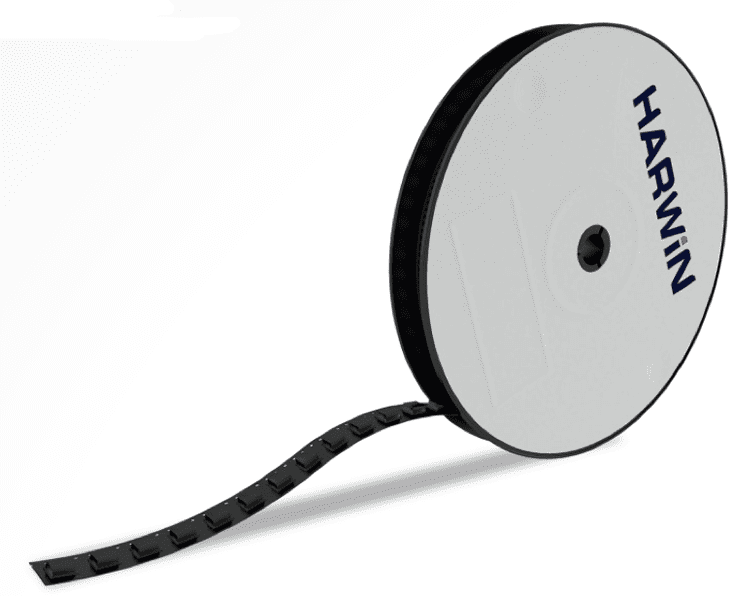

Lowers cost. Pins only need to be soldered to one board, and the mating side typically only needs a small pad to make a connection. Both parts can be provided in Tape & Reel packaging for automation and reduced cost during manufacture and assembly.

Key considerations when selecting a pin

Designers should ask a range of questions to help select the most appropriate pin for their application. The goal is to achieve a stable and reliable connection.

Size – Choose the right working height, not the free height.

The free height of the pin is the overall length when the spring is fully extended, whereas the working height is the length of the pin when depressed. The mating contact should ideally be compressed to the working height to ensure signal continuity.

How much space does the application have, and how small a pin is required? Harwin’s Spring-Loaded SMT Contacts pogo pins range in free heights from 2.4 mm to 7.3 mm and working heights of 1.85 mm to 6 mm for surface mount pins without location pegs. Whereas surface mount pins with location pegs range in free heights from 2.8 mm to 8.2 mm and working heights from 1.9 mm to 6.4 mm.

Using a spring pin at the right working height will increase the performance and the durability of the connector significantly. For example, Harwin’s P70-2200045R has a free height of 5.5 mm, a maximum working height of 4.7 mm, a normal working height of 4.5 mm, and a minimum working height of 4.2 mm.

Electrical requirements

What is the current handling? Spring-loaded pins typically carry both signals and power, and Harwin’s pogo pins deliver a lower power charging current of 1 or 2 A.

Easy assembly with locating pegs

Does the application require locating pegs? Pins with locating pegs will help with stability and assembly, and assist with surface mount placement, making them ideal for automated assembly systems. Some pins can be supplied in Tape & Reel packaging, whereby they are provided in the tape vertically, with disposable pick-and-place caps over the rounded mating end. These caps provide a flat area for vacuum pick-up.

Technical support

When specifying pogo pins it is also valuable to look beyond the technical aspects of the pin design and consider the manufacturer. For example, select pins from a reputable manufacturer that also provides technical support and design-in assistance.

Availability

The speed at which designers can purchase pins and how quickly they can be delivered is also an important aspect. How readily available are the pins, and can designers have access to rapid sampling?

Spring-loaded pins are reliable and durable contacts that support the demands of modern consumer electronic devices, including miniaturization and portability. Experienced manufacturers can help specify the contact that is most appropriate for the application, ensuring excellent connectivity and a high-quality device.

To learn more about spring-loaded contacts, visit Harwin.

Like this article? Check out our other Custom and Manufacturing articles, our Special Topics Page, and our 2023 and 2022 Article Archives.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Improving Device Reliability with Spring-Loaded Contacts - August 15, 2023