Sensors Take Center Stage as the Need for Data Grows

Updated: January 2023

Smart connectivity has grown out of the need for better information gathering. Sensors allow more data than ever to be collected at the source and transmitted to stakeholders where it can be analyzed quickly for decision-making, troubleshooting, maintenance, safety, and other critical functions.

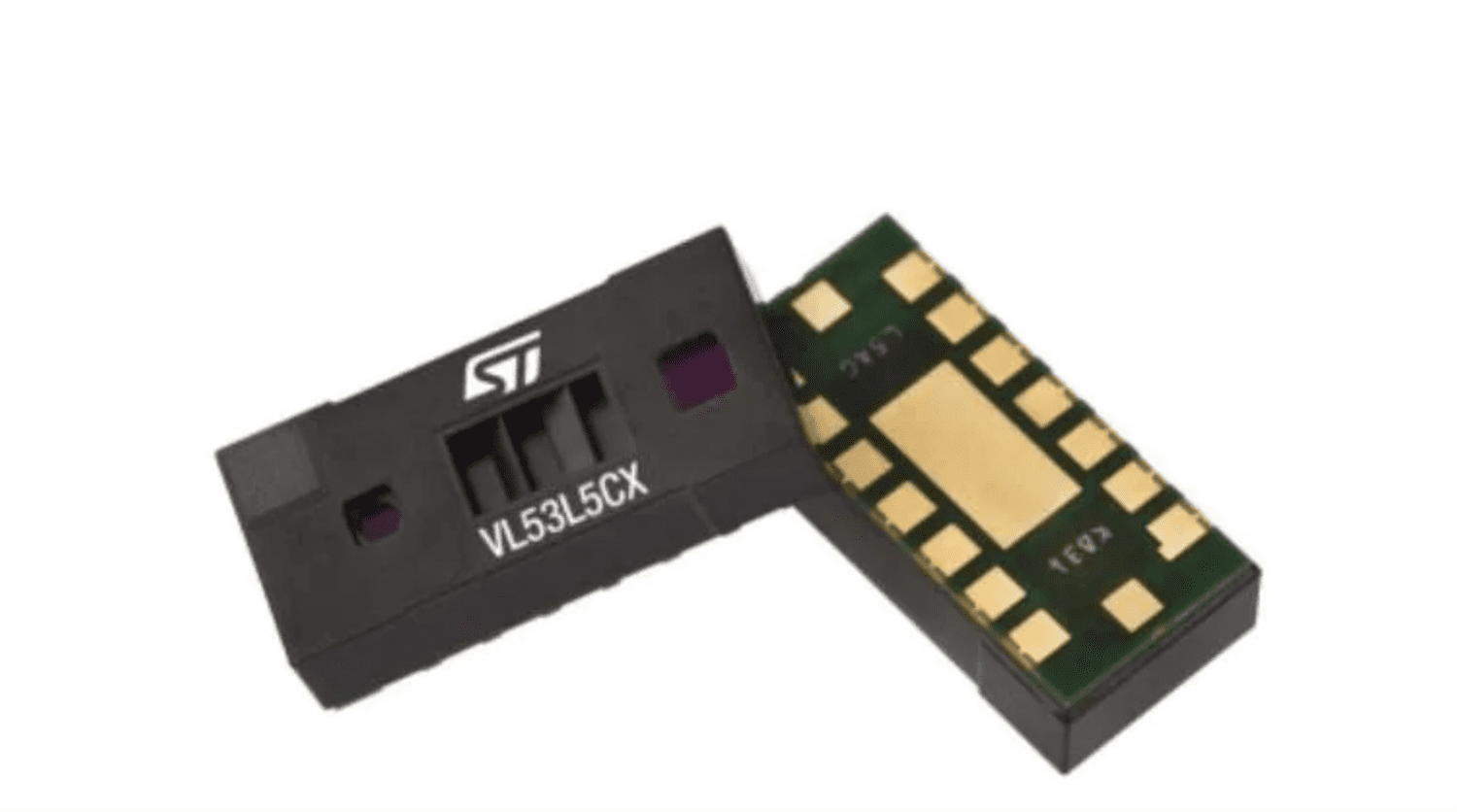

Sophisticated sensors are employed to gather and transmit specific, timely, and accurate data in a variety of settings. Sensors monitor temperature, pressure, shock and vibration, light, speed, motion, flow, and a host of other factors to ensure operational efficiency and safety as well as the health of equipment and people. In a world of increasingly smart devices, sensors increase functionality, precision, and safety. Most types of sensors are specialists, focusing on a single job. Others are versatile, such as Time-of-Flight (ToF) sensors, which have diverse capabilities, including object detection, depth estimation, and object classification. Applications include inventory management (counting), tracking people, and monitoring parking areas. ToF sensors can also be integrated and expanded into more unique applications.

Mouser Electronics stock STMicroelectronics’ new Time-of-Flight proximity sensors, a 8×8 multi-zone ranging sensor with a wide field of view.

Sensor Technology Improves Deep Foundation Construction

Molex partnered with Pile Dynamics Inc. (PDI), an innovative technology company serving the construction industry. One of PDI’s products, the innovative Thermal Integrity Profiler (TIP), uses sensors to test the quality of deep foundations as they are being built in the ground or underwater. PDI is known for maximizing its use of technology. The company’s ability to gather information and make it accessible instantaneously, via the cloud, rather than in hours or days, sets its products apart from other integrity testing methods.

Molex incorporates sensors directly into the Thermal Wire cable to speed and simplify production of the Thermal Integrity Profiler from Pile Dynamics Inc. (Photo courtesy of Pile Dynamics Inc.)

TIP uses a series of sensors, spaced a foot apart on a wire that is installed in a drilled foundation. The sensors record a temperature reading every 15 minutes from the time the concrete is poured into the drilled shaft. The information is readily available on PDI’s cloud database. “Our mission is to catch things ahead of time so that there’s a quality foundation that’s poured each and every time,” said George W. Piscsalko, PDI production manager. “That level of accessibility is really something that stands out compared to other technologies out there. Time is money and our product is able to give results to the engineering firms much quicker than other technologies. And we are able to see it during the pour.”

This intelligent IoT platform from Wearin’ captures in-mission data from connected sensors and devices.

Sensors Keep Personnel Safe

The connected devices, found nearly everywhere today, and the volume of data they generate creates huge challenges for design engineers. Collecting information that supports mission-critical applications for security forces and law enforcement, firefighters, first responders, and lone workers or workers in remote locations, presents two specific technology challenges. The first is how to integrate end-to-end connectivity to establish the physical connection between interoperable sensors and communication devices in demanding environments. The second is how to optimize and harmonize power and data flows at increasingly higher performance and speeds, as well as transmit data to the cloud to be processed.

Wearin’, part of Conextivity Group along with Fischer Connectors, is an intelligent IoT platform that captures in-mission data from connected sensors and devices. Digitalizing the status of people in the field enables users and decision makers to obtain real-time insights based on an individual’s location, well-being, and environment. This level of timeliness and accuracy is crucial for detecting, managing, and preventing crisis situations. Wearin’ incorporates the right sensors and devices into the gear of personnel in the field, as well as in vehicles and in their surroundings to capture and process the data that is sent to the users and the decision makers. Coordination and faster response are enabled with automated alerts and two-way communication. Incident detection, such as heat stress and acute stress, man down or an attack on an armored vehicle, is accomplished with AI-powered data processing and helps prevent future risks.

Sensors Keep Industry on Track

Many types of sensors are used in industrial automation including level sensors, electric current sensors, humidity sensors, pressure sensors, temperature sensors, proximity sensors, heat sensors, flow sensors, fluid velocity sensors, and infrared sensors. Here is a look at a couple of these.

Optical sensors are used throughout industrial manufacturing. Also called photoelectric sensors or photoeyes, they use a light transmitter such as infrared and a photoelectric receiver to detect the absence, presence, or distance, of an object.

Optical sensors come in different functional types and packages. Opposed or through-beam sensors and retroreflective sensors detect an object when it breaks through a beam of light. Through-beam sensors have the beam of light between two sensors, while retroreflective sensors have it between a sensor and a mirror. Proximity sensors, detect an object using electromagnetic fields. An optical sensor may have self-contained optics and electronics, and perform its own modulation, demodulations, amplification, and output switching.

Omron’s compact E3FA series of photoelectric sensors, supplied by Mouser Electronics, is designed for machines that never stop. The series includes optical sensors such as ambient light, RGB, and a range of photointerruptors.

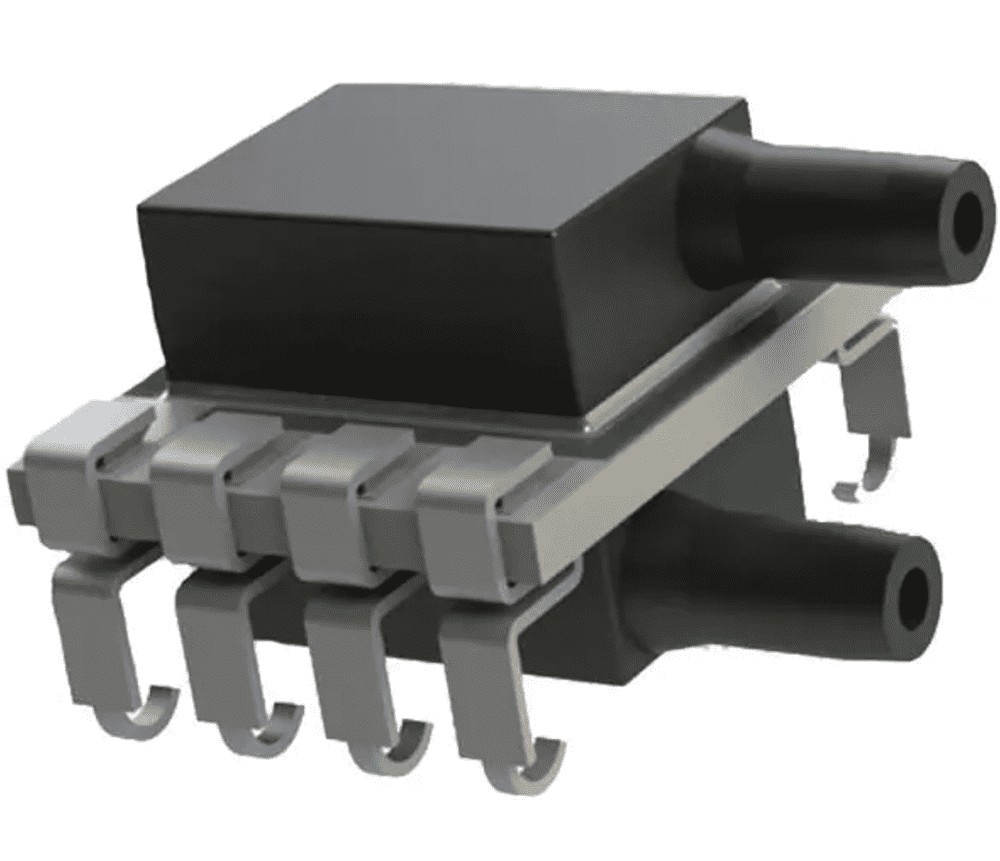

Pressure sensors — also called pressure transducers, transmitters, or meters — are typically used to measure the pressure of gases or liquids, or to calculate fluid and gas flow, speed, fluid level, and altitude. They sense pressure and, based on the pressure applied, convert it into an electrical signal.

Common applications include measuring the level of water in a tank, isolating a gas leak or water pipe leak, measuring pump pressure, measuring pressure in a high-temperature environment, measuring pressure differences on both sides of a filter bag (baghouse), and measuring pressure in food and beverage bottling lines.

Bourns pressure sensors, available from TTI, are used in industrial applications as well as in medical devices, and consumer appliances that require accurate measurement at low pressure.

ICC supplies TE Sensor Solutions M5200 pressure transducers, part of the Microfused line. This modular solution is designed for the measurement of liquid or gas pressure.

Sensors come in many forms to serve a variety of purposes within and beyond industrial applications. They no doubt will continue to evolve to provide more and better information for even greater safety and efficiency and more informed decision-making.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Molex, Mouser Electronics, Fischer Connectors, TTI Inc., Interstate Connecting Components (ICC), and TE Connectivity.

Like this article? Check out our other Sensors, Antennas, and IoT articles, our Sensors & Antennas Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Sealing Success: Overmolding for More Secure Connections - April 23, 2024

- Medical Cable Assemblies Product Roundup - April 23, 2024

- Mezzanine Connectors Product Roundup - April 16, 2024